Subtleties of the process of attaching the clapboard to the clamps

Wood panels are used in modern construction almost everywhere. They are framed by the surface of the facades, trim the pair and attic, of which erect fences and other structures. Kleimers have recently been actively used for fixing lining. This article will tell about the intricacies of fastening material with such details.

Alternative fasteners

Until recently, in the process of finishing works with clapboard, craftsmen often had to decide which fastener to use to fix the material. The choice was made between nails and screws. Today, this question is no longer so acute, because now the method of attaching the wall panel to the surface using the so-called cleats is used as an alternative.

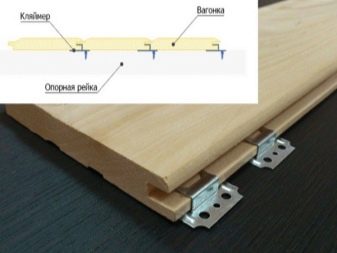

Kleimer is a stamped bracket of a special form. Such elements are mounted on a previously prepared base and attached to it by means of nails or screws. The hook of such a klyaymer contributes to a strong fixation of the wall panel, completely hiding all the fastening details from the eyes. In this case, hardware of this type is used not only for the installation of wall paneling.

They are also often used for fixing PVC panels and installing MDF elements.

Benefits

The hidden method of fixing the wall panel through kleimer gained increased popularity with good reason. Thanks to its use, the finishing process has received significant acceleration. In addition, the use of kleymernyh hardware reduces to zero the risk of damage to the material, the appearance of splits and cracks, which often happens when using standard fasteners made of nails and screws.

Klyaymery are selected individually under the type of lining used in the work. The high degree of fixation of such hardware is a guarantee that in the future, the boards fixed with such brackets will be fixed, will not allow backlash and will not be loosened.

There will be no extra holes from them.

The use of Kleimer does not provide for the use of any additional components. To carry out the installation of the brackets themselves and nails or screws, which complete the fixation.

All products of this type have anti-corrosion coating or are made of stainless steel. Due to this, reliability and service life of parts increases many times.

Due to the low cost of klyaymerov and their availability for buyers, they are a vivid example of the optimal combination of price and quality.

The installation of the wall panel and its dismantling in this way are performed rather quickly. Klyaymery virtually invisible, so the design has a holistic appearance, without gaps and indents, any damage and protruding parts fasteners such as nail heads and heads of screws.

Installation with the use of such hardware is simple, does not require the use of special tools.

It can hold even a person who does not have construction qualifications.

Hardware consumption

The method of calculating the number of brackets required to perform the work is based on the consumption of fasteners per square meter of material.As is known from practice, about 20 staples are usually spent on this unit of area. More precisely, their number is calculated based on the length of one element of the wall paneling and the determination of the pitch between the battens of the batten. Here, standard values for such frameworks are typically used.

Next, the length of the rolling plate is divided by the pitch of the sheathing framework, a unit is added to the result. The resulting value is multiplied by the total number of lining slats, which is planned to be used for finishing. Then it is necessary to calculate the total number of packages with clears. It is calculated by the number of ridges in the box.

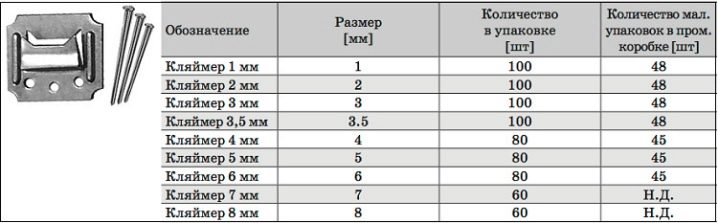

According to the standard, each package contains 100 staples.

Selection method of mounting bracket

The choice of claimers depends on the type of wall panel used in the finishing work. Varieties of material vary in thickness and weight of sheets, so the brackets for fastening must have the required size and height of the tongue corresponding to the task.

Plastic lining and finishing elements made of MDF can be mounted on clamps having a height of about 1-2 mm. Hardware with a three-millimeter tongue is used to install materials from chipboard.

For fastening of eurolines used clamps, the tongue height of which is 4 mm. If ordinary wooden wall paneling is used to finish the house, then to fix it to the working surface, brackets 5 mm high are used. The most powerful fasteners are needed for the block house. It should be fixed with hardware clips with a tongue 6 mm high.

The most reliable are kleymernye brackets, whose thickness is equal to 0.5 mm. They are made of steel with zinc coating, so they are not afraid of corrosion and are durable. Due to this, parts can be equally successfully applied both to interior decoration and to exterior works.

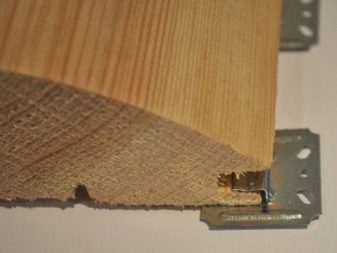

Today, clays with spiked hooks are also on sale. These brackets are driven into the ends of the wall paneling, creating the effect of additional fixation of the wooden board. There are several varieties of such elements. Correctly choose the appropriate option, based on the thickness of the board on which the part will be mounted. Klyaymera No. 3 and No. 4 are selected for the eurolining, for No. 5 and No. 6 for the aspen and linden boards, the No. 2 for the clapboard is taken for plastic.

The nuances of editing

As already mentioned, to fasten the wall panel, the Kleimers are placed on a panel, which is then fastened with nails or screws to the wall or crate. When working you will have to use the square, tape measure, hammer, screwdriver, screwdriver and building level.

Under the clapboard is mounted obreshetka. The purpose of its installation is to align the deviations of the walls and the ceiling vertically for the most accurate installation of eurolining panels.

If the crate is created from wooden bars, they should be treated with an antiseptic to prevent rotting. The second option may be a metal profile, also used for fixing sheets of drywall. In this case, it can be used due to its moisture resistance. The voids between the bars or the metal profile of the frame are filled with insulating material.

The whole process of installing the wall panel should take place with continuous monitoring of the accuracy of the placement of its elements and their leveling. The distance between the individual bars obreshetki should not exceed 550 - 600 mm.

Nails or screws for fastening clamps are taken at the rate of 2-3 pieces per bracket.

Fastening with just one element gives poor-quality fixing of the panels, which can lead to deformation of the structure.

Fixation methods

Installation option is selected depending on the location of the panels. If horizontal lining is used, the element is mounted at the very bottom in close proximity to the floor.

Kleimer fastens on the spike panel. It is installed in the proper place, and fixation is performed with nails or screws that have been passed through the holes in the body of the kleimer and clogged or screwed into the crate. Each bracket usually has at least three mounting holes, but you can also use two of them.

The first panel of the wall panel is placed in the body of the bracket on a hook. Subsequent panels are inserted into the groove in the groove and are fixed with a clamp. The thickness of the tongue part allows you to enter the next carriage panel into the groove of the previous one, with the kleimer mounted on it. So the whole process is repeated cyclically.

The first and last boards are fastened with nails.

Vertical installation of the wall paneling is carried out by very tightly pressing the butt with the comb to the wall surface and fixing the bracket with hardware. In this case, the panels should be cut to exactly the size to avoid cracks in the body of the structure. It is worth remembering that liquid sealants should not be used to treat joints.

It should be noted that the horizontal method of installation of the finishing covering of the lining is one of the most popular. Some varieties of this material (for example, "American" and "quarter") are attached to the surface they trim only by this method.

If you plan to set up a steam room in a Russian bath or sauna, then you will need to install the slats upwards with a spike. It is in this position that water and steam condensate will flow along the wall without stopping.

Installation works in this case start from the ceiling.

Vertical installation of panels visually increases the volume of the room, visually raising the ceiling. This technique is usually used when finishing baths and other rooms that do not require special originality of design. Installation of panels with this method can be conducted from any angle, placing the first board outward groove. It is recommended to fix the clapboard to the ceiling surface, moving from the light. This avoids the formation of shadows between the trim elements.

There are also diagonal and combined-patterned styling methods. Such decorative installation methods are often used to decorate walls and to finish ceilings inside residential premises.

The artistic combined-patterned method involves the installation of elements of lining at different angles. As a result, you can achieve a very interesting picture, make the interior more expressive. However, this version of the installation of the material requires considerable professionalism. Unlike other methods described above, it is not available to novice performers, despite the simplicity of fastening parts.

You can learn about the non-standard method of fixing wooden wall paneling by watching the video below.