Features and scope of eurolining

Walls inside the house are made in various ways. But wallpaper, tile and decorative panels are not suitable everywhere. Sometimes you need a universal material that allows you to cover the surface of a residential building inside and out.

Special features

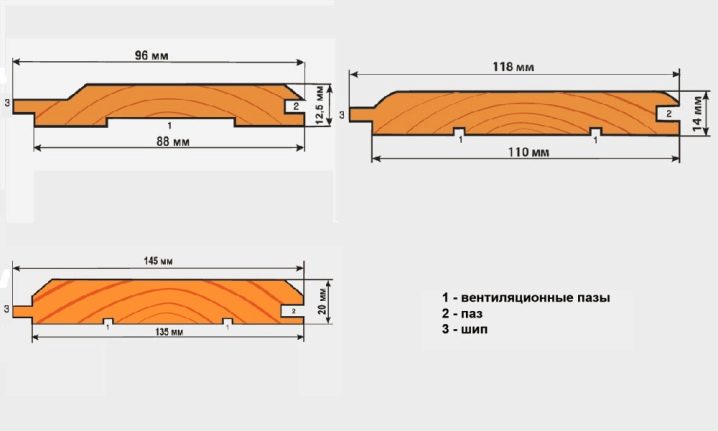

Euro lining - this is a coating that is formed from a simple board. It is processed in all four planes and is equipped with a groove-thorn joint. The typical width with spikes is 96 mm, without it - 88 mm. The thickness of the coating reaches 1.6 cm. Processing is carried out in the framework of a single technology, wood from one batch is necessarily taken.

Lining differs from the “simple” version in that:

- it is made more carefully;

- divided into varieties;

- different sophisticated profile.

The moisture content of the feedstock is a maximum of 15%, that is, chamber drying is obligatory.It is forbidden to classify products as shorter than 120 and longer than 400 cm as eurolining. The tongue is made deeper, and the spread of dimensions between individual parts should be minimal. The back side is covered with furrows, draining condensate. Professional manufacturers are sure to wrap the goods being shipped with a film that shrinks under the action of temperature.

Kinds

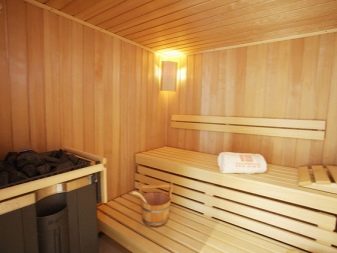

Great importance for the correct choice is the evaluation of the properties of the breed. So, the linden is considered the most qualitative and worthy material. An array made of it perfectly manifests itself in places with high temperature and humidity, such as a bath or sauna. Superb performance for consumers to pay increased prices. The only acceptable alternative is aspen.

Wood conifers are recommended for installation both inside and outside the houses. But the hardwood is allowed only in the interior decoration.

The advantages of aspen batten are:

- light color;

- ease;

- mechanical stability;

- zero risk of cracking.

Pine has an average density, quite heavy, immediately recognized by the characteristic reddish-yellow ebb. Gradually, the color becomes somewhat darker. Subject to processing with special mixtures, pine eurolining is extremely resistant to the effects of microscopic fungi, gnawing insects. The glued block can be easily obtained, does not cause technical difficulties coloring and impregnation with stain. Larch varies in tone from light yellow to red-brown.

This coating is durable and almost not warped. Even negative weather conditions will not affect the properties of this material. Good results are obtained using cedar. Similar wood differs in durability and value, looks more beautifully in large quantities used species. Another advantage of it is the good aroma provided by healthy substances.

The difference between spruce lining is a light yellow color and solid fortress. It is quite simple to process and paint it, so the cost is relatively acceptable for most people. The use of other types of wood raw materials is practiced very rarely.

Scope of application

Spruce wood is used on the balconies, but only after specially impregnation.The point is low resistance to water, significant temperature and attacks of harmful insects. Larch is used both inside and outside the house and is very much appreciated due to its practical qualities. Products from ash and oak are recommended for living rooms with low humidity, they look beautiful and last for a long time. In order to apply eurolining for interior walls, the material is carefully prepared, preventing rotting and swelling.

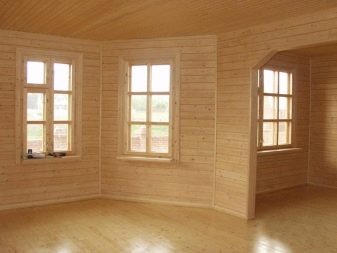

Contrary to popular belief, European lining is suitable not only for outbuildings. Modern designers and developers have managed to refute such an assessment. Wooden blocks are perfectly combined with tiles, various wallpaper, plaster and so on. Lining can be applied on the walls and on the ceiling to the same extent. But in the second case, the stacked canvas should be placed as closely as possible.

Whether it is necessary to specially process the boards of eurolining before laying on the ceiling, interests many. There is no special need for this, it is only required to dry the material at room temperature for at least 14 days. It is extremely undesirable to speed up this process at home.Larch is not suitable for a bath, there it will very soon take on an unpresentable look. Coniferous wood is also bad there, especially in the steam room, as careless touching can cause a burn.

Alder, due to the increased concentration of tannins, is excellent when finishing the steam room. Such a tree abundantly absorbs water and passes a little heat. Birch has a bright texture, but does not tolerate high humidity. But it is very useful in the waiting rooms or in the rest rooms provided it is antiseptic. For your information: fixing lining in damp rooms, unlike the usual room, must also be protected from moisture.

Euro lining even better than the usual variety suitable in the bathsbecause it is equipped with a deep joint of a groove and a ridge, differs in the increased thorn. Water drainage is more active. Hidden behind a layer of material the surface is better ventilated. With vertical display, an increase in the tolerated temperature is achieved by reducing the resource. Basically, this method is suitable for steam rooms with dry air and saunas.

Sorta

Classification lining is determined solely by the quality of raw materials.There are no standards for this. More precisely, there is still GOST 8241-88 and East German DIN, but both regulatory acts do not meet modern realities for a long time. The standard from the GDR, for example, allows even for class A to drop knots up to 0.5 cm wide; in category B is not considered a violation of the appearance of bluish shades.

If you need to get the product grade "Extra", usually used the technique of splicing boards. Without it, would have to pay for such a product absolutely unimaginable amount. After all, the number of ideal pieces of wood of sufficient size, even in the forest of the highest quality, is small. To protect the material, it is often even transported in a vacuum container. In the delivery set, fasteners are most often present. A rare consumer of the 21st century will agree to buy products with such characteristics. A typical description of the European clapboard of the Extra group according to technical standards provides for the complete absence of cracks. Obtaining the necessary material is carried out using a variety of mechanisms.

In addition to the drying chamber, you need:

- circular saw;

- end;

- fugovalny;

- surface gauge;

- four-sided grinding machine.

The authenticity of the category must be verified during direct examination. No marking and supporting documentation will replace this test. If the seller refuses to demonstrate the product, it is better to refuse. It is recommended to check selectively several boards from above, from the middle and from the very bottom. As for category A, it may even be better than premium products or slightly worse, it all depends on the specific manufacturer.

What is important, you should not cover with paint the detected defects, if they meet the requirements for the grade. For masking apply only varnish. Additionally, wax and oil help to decorate the surface and give it a luxurious look.

Even the worst grades in the Lining are unacceptable:

- through cracks;

- cracking, reaching the end;

- coverage of rot more than 10% of the material;

- the appearance of more than 3 wormholes on 1 rm. m

Dimensions

Having dealt with the varieties of material, it's time to get acquainted with its standard dimensions. The size of the groove is 0.9 cm (0.4 cm larger than that of simple types of lining). If the lamellae are joined, the groove may increase to 1.5 cm.The length varies, as already mentioned, from 1.2 to 4 m; standard thickness varies between 1.3, 1.6 and 1.9 cm.

Width has such standard values as:

- 8;

- 10;

- 11;

- 12 cm

The specified dimensions are suitable for facing even a large room (hall). Spikes of 8 and 9 mm equally meet the standard requirements. Differences from typical dimensions in length are no more than 0.5 cm, in width - 0.1 m. The maximum deviation of thickness is 0.07 cm, and in the spike scale is only 0.05 cm. These requirements are not just invented, but in order to eliminate the occurrence of cracks and loss of appearance.

Colors

Coloring eurolining - no less important point than its size or other moments. Most manufacturers paint this material in one way or another. A universal solution in many cases is white or beige. If you want to decorate the interior cardinally apply any bright paint. It is used: even the initially low-key surface can be transformed by hand.

Slightly indifferent warm shades are an excellent choice in bedrooms and kitchens. But the study or corridor, which are purely utilitarian in nature, are painted mainly in the cold range.Returning to the white paint, it is worth saying that it should be used only where there is the least risk of clogging. Be careful with pearl shades. Despite their external effect, they get extremely dirty very quickly, and in bright rooms this only intensifies.

Despite the comparative simplicity of self-painting, industrial coating is still preferable. It is known to be even and clear. The quality of the paint is strictly controlled at the plant, there they even check it in the laboratories selectively, which is impossible in everyday life. There is no need to talk about a lesser expenditure of time and effort, about eliminating errors Moreover, the product arrives already dried and fully fit for installation.

Tips

Installation can occur in various ways. After impregnation the wooden slats dry for 48-72 hours, at the same time the tree adapts to the microclimate of the premises. Then they form a crate for the rails, attaching 1-inch pieces of wood at a distance of 500-600 mm from each other. When facing the outer surfaces, it is better to lay a heater in the gap from the surface to the batten. Its choice is made individually.

After completing the preparation, mount the coating itself in a vertical or horizontal course. The second option is chosen mainly by those who intend to expand the perceived space. It is advisable to orient the slatted grooves down to eliminate the accumulation of dust and dirt. Quality control is done every 7-10 rails. The last board will be more difficult to adjust, and a lot of time will be spent.

Vertical layout implies the ability to visually raise the ceiling. In addition, it differs in that it allows you to put lining of various sizes. It is required to act from a corner, boards fasten in grooves of the previous laths. The first board is attached to the nails, the caps of which are overlapped with decorative caps. Fastening clamps made on the back wall. Whether to conceal caps that are driven inside the finishing board is decided by the builders themselves.

In addition to the division of eurolining into varieties and its fastening, attention should be paid to painting. Situations are different, in some cases, the color that initially seemed nice, in reality did not go. Or changed the design priorities.Or a new repair is being made, after which the old coloring becomes unacceptable. It is important to distinguish between compositions for internal and external works and never to confuse them in principle.

Before staining using protective mixtures, toning stain. Also, instead of paints, varnishes and oils for wood coating are widely used. Which of these options to choose - depends largely on personal preferences. We must not forget that the color on the monitor screen or in the printed catalog, even when opening a can, will not be the same as at the end. Sometimes you have to paint for the test barely noticeable area.

Snow-white textiles, if they dilute the wall paneling and timber, will be perceived even fresher. Bright, juicy walls as a background for light furniture fit perfectly. But it is unreasonable and uncomfortable to paint the entire paneling in an ideal white range. It is much more correct to make a small digression from it, to add a bit of a different color, even if it is only a low tide. To reduce paint consumption, wood primer with antiseptic additives.

Difficult tones with a sense of the presence of a layer of dust help set a sense of thoughtfulness, demonstrate a deep intent.A great move is a combination of colorful walls with a white floor or with a darker ceiling. But at the same time it is not necessary to combine all three elements, to make a competent decision whether it is justified, only trained designers will be able to. Prior to installation, remove all foreign matter and contamination from the surface to be trimmed. The crate is placed at a right angle to the future course of the wall paneling.

Work preferably from the corner. If you drive a nail into the first board or tighten the bolt, you can simplify the work. But the perception will be spoiled, and if necessary it will not be possible to dismantle the paneling, if not to break the integrity. Where better to use klyymery, besides they are more reliable. And if anything, remove the fasteners work out and without damage to the lining.

Lining, which is to be mounted vertically at some distance from the floor, it is advisable to support the "pallet". So called rail with a convex contour, held on the crate.

It is necessary to dismantle the wall panel not only if it no longer pleases. Gradually wood will lose the varnished covering. Its color will also deteriorate.Reconstruction of these characteristics best of all passes after removal of blocks. All work should be done at normal room temperature. Ideal humidity for installation and reconstruction - from 50 to 70%.

Restoration of appearance begins with the removal of the finish and processing. Then the material is stained twice (it should dry). Then put a varnish, dry it under normal conditions for two days. Then mount the wall paneling on the batten. Waiting time should not be wasted, the crate should also be investigated and repaired.

The original step - drawing on the walls of eurolining, differing in tonality. Different rooms located nearby are decorated with contrasting colors. An exception is made for completely dark colors, which only create a depressing impression. Another way to show your extraordinary approach is to choose an atypical ornament. So, along the perimeter of the board, you can put it in the form of a square, the inside of which is trimmed diagonally.

This practice is applicable both in isolation from color delights, and in close conjunction with them. The big role is played not only by a coloring, but also the general stylistic plan.For example, in a country setting, white color and its various shades are most preferable. No less good, he will be in the Scandinavian interior. Then the appropriate colors are selected for walls and ceilings.

Lining allows you to create and an attractive soft interior in an ecological manner. Kitchens are usually either fully sheathed, or they emit only dining areas with this material. An interesting and not yet beaten move - the packing of panels exclusively at the bottom of the wall. The use of moldings gives good results for the separation of heterogeneous fragments. If there is no understanding in which room the wall panel is most appropriate, you need to focus on the bedroom.

Varnish that will be applied to the material should not be intended for baths. Where it is better to use special formulations for exterior or interior work - depending on what is planned. Installation of eurolining onto brick and reinforced concrete walls without lathing is not allowed. On a wooden surface, it can be started immediately. But only under the condition of an exceptionally flat surface.

Beautiful examples of interior decoration

White lining can look quite attractive even in a very bright interior. Skillful use of black and color accents, even if they are inserted concisely, can demonstrate its charm in this case. For color contrast it is not bad to apply various decorative objects and patterns on textiles.

A light yellow surface looks pretty good if a dark cherry shade is used for contrast. But it is better not to focus blindly on the finished samples, but to take into account your own taste and specific situation; By observing these principles, you can get a high-quality interior that will last as long as possible.

On the installation of eurolining you will learn in the next video.