Mortar selection criteria

When building masonry from brick, building blocks, as well as when facing surfaces with brick and clinker tiles, special solutions that will bind individual building elements and ensure solidity of the masonry cannot be dispensed with. For these purposes, it is convenient to use dry masonry mortars.

Special features

Masonry mixes are compositions of dry elements that, when filled with water, turn into a solution suitable for bonding masonry elements - bricks, blocks. We can say that the masonry mortar is an analogue of the classic cement-sand mortar, although this is not entirely accurate. Modern mixtures are maximally adapted to a specific type of building material, and also possess improved technical characteristics.

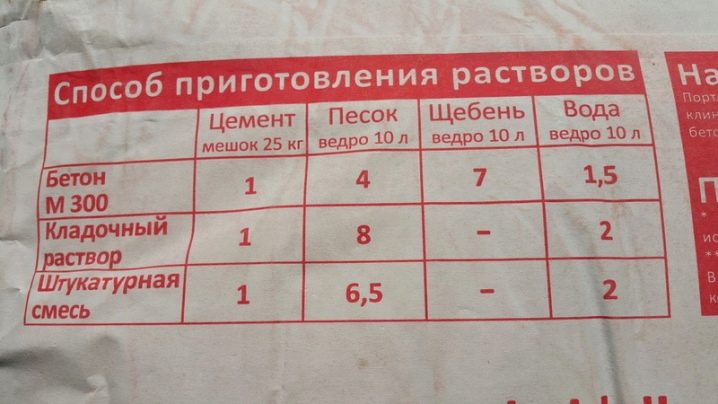

Of course, such a composition can be prepared by yourself, but it is not always possible to find all the necessary ingredients., and also to achieve optimal proportions.The advantage of ready-made compositions is the accuracy of the volume of ingredients, as well as ease of use. It is enough to fill them with water and thoroughly mix with a construction mixer or a drill with a special mixing nozzle.

Despite the variety of types of mixtures, they all must meet two main parameters:

- be durable (for this quality in the composition of the cement meets or its version - Portland cement);

- to be plastic (due to this quality it is possible to lay the solution in a thin layer, which in some cases is a prerequisite for installation, for example, when laying fireclay bricks).

The strength of the solution is estimated based on the strength of individual components of its composition, as well as indicators of its adhesion. It is clear that increasing the strength of the solution allows you to increase the strength indicators, the solidity of the masonry. However, an excessive increase in the strength of the mortar reduces the ability of the masonry to adapt to the stresses that inevitably arise during operation. This, in turn, provokes the appearance of distortions of the building, the appearance of cracks. Thus, it is important not to strengthen the manifestation of individual characteristics, but to achieve their harmonious and complex manifestation.

To give the mixture the required color, mineral pigments are added to it, providing one or another shade of the solution, which makes it possible to achieve the identity of the color of the seam with a hint of brick. If the laying is made of materials of light shades, then a mixture based on white Portland cement is used.

For masonry hollow bricks or cellular concrete blocks use special compositions that have insulating properties.

The basis of such compositions is always the same:

- cement or clay, acting as a binder;

- fine sand or crushed stone;

- mineral components that provide one or another property of the finished solution.

Practically all ready-made mixtures contain substances that retain moisture in the solutions, which helps prevent bricks and blocks of moisture from being pulled out of the solution, as well as reject pre-soaking of building materials.

Kinds

There is a wide variety of masonry mixes, but they are all conditionally divided into two types:

- General construction. Suitable for walling residential and public facilities. The most widespread compounds M-200 and M-150, characterized by high performance properties.Virtually every manufacturer uses these mixtures as a basis, adjusting the properties of the composition with the help of additives and modifiers.

- Special. Such options are used for the construction of facilities operated in an aggressive environment, including those used for masonry pools, stoves, fireplaces. In addition to strength, these compounds must demonstrate certain additional characteristics: fire resistance, heat resistance, increased moisture resistance with constant contact with the liquid and other indicators.

Depending on the composition and scope of application, there are also some types of masonry mixes:

- Cement. Such a mounting mixture is characterized by increased strength, rigidity, but does not allow to obtain aesthetically attractive seams. The composition is used in private construction (mainly when laying the foundation), suitable for the construction of high-rise buildings.

- Cement sandy. These are universal mixes suitable for most types of masonry and all types of bricks. Often this mixture is the basis for other compositions.

- Cement-clay. Suitable for low-rise buildings, widely distributed in private housing. The introduction of purified clay medium-fat allows you to increase the water-repellent properties of the finished solution.

- Cement-lime. The introduction of lime in the standard cement-sand mortar allows you to increase the life of the solution, produces a small insulating effect, however, reduces the moisture resistance of the composition.

- Limy. It is suitable only for small low-rise buildings, since it is characterized by reduced strength and increased fragility.

There are also universal compositions, which are used by builders for all types of bricks, cellular building blocks, artificial stone. They do not apply only to clinker bricks or tiles, since the compositions for these materials must have a higher viscosity. However, professional builders prefer to select a special masonry mix for each type of material.

For example, for large-sized cellular concrete blocks, ceramic blocks with a porous surface, concrete analogues based on porous aggregates, it is recommended to use insulating masonry mixtures.By itself, such masonry has high heat loss, which allows the thermal insulation solution to level.

Warm masonry is obtained through the use of solutions with perlite or other small fractional bulk insulation in the composition. In this regard, this mixture may have another name - perlite.

To increase the thermal efficiency of the laying of foam and gas blocks also allows reducing the thickness of the masonry joint to 2-3 mm. This allows you to prevent the appearance of "cold bridges", but it is possible only with the use of thin-layer adhesive mixtures. Despite the smaller thickness (which also leads to a more economical consumption of the composition), adhesive solutions have improved adhesion.

For the laying of stoves and fireplaces requires a refractory mixture. As a rule, it is a clay-chamotte version, consisting of a special, pre-calcined clay with the addition of other elements. A feature of this mixture is the ability to withstand heating above 1 thousand degrees and at the same time become even more durable. The mixture for the stove or chimney masonry should be not only refractory and heat-resistant, but also environmentally friendly.

If the work is carried out at negative temperatures (of course, this method is not recommended, but all sorts of situations happen in life), then the so-called “winter” masonry mix will do. In its composition there are modifiers that accelerate the setting of the seam, preventing the manifestation of the negative properties of the components of the mixture with a decrease in temperature.

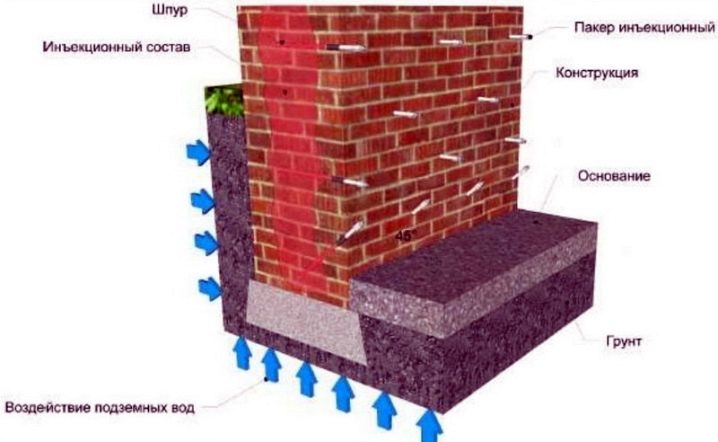

For surface and underground works also require different compositions. The density of the former is usually higher, and they are characterized by increased strength, the ability to withstand the pressure and the action of groundwater.

When jointing the facade, it is important to select the appropriate shade of the seams. For this there is a color and white mixture. The first option corresponds to the variety of shades of colored bricks, and the second is prepared solely on the basis of white Portland cement.

White mixture, as a rule, is used as a facing or in the restoration of the seams of buildings after many years of operation. Typically, this cement-sand compositions with the addition of modifiers and milk of lime.

Scope of application

Masonry mixes are used for the erection of masonry from all types of bricks, foam blocks, ceramic and concrete cellular blocks, slabs of wood concrete, gypsum plaster blocks.There are compounds intended for operation in aggressive environments: in mines, tanks in contact with water, industrial and household stoves, masonry, exposed to chemical elements.

Laying paving or facade clinker tiles can also be made using these compounds. They are suitable for cladding and repairing seams after prolonged use. Color compositions allow you to create a monolithic exterior masonry, or, on the contrary, to create an original jointing slightly darker or lighter than the shade of the brick.

Manufacturers

The leading manufacturer of dry masonry mixes is PEREL. In its lineup a large number of product modifications, so for each type of work, you can choose the most suitable option. Available in both white and colored mixtures, the latter totaling up to 14 shades.

The range includes summer and winter mixes. The first option can be used at temperatures up to +30 degrees, the range of application of the second - from -5 to +10 degrees.

In general, products can be divided into compositions for clinker bricks, analogues of imported bricks and products for domestic bricks and blocks. The differences between the compositions are due to the indicators of their water absorption.

A large palette (13 shades) of color mix is also offered by the Finnish manufacturer Lakka. In its lineup there are compositions for exterior and interior work, a separate line for clinker bricks. Buyers note the optimal combination of price and product quality.

For private housing construction, Weber Vetonit’s mixtures for silicate and ceramic bricks have proven themselves well. It is convenient to work with these mixtures, even without having the necessary building skills.

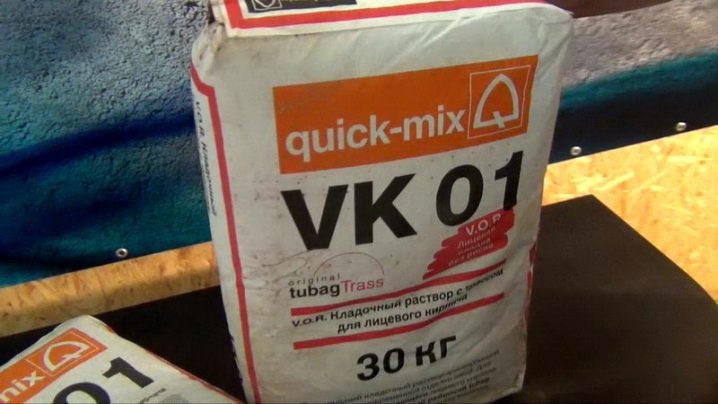

Products manufactured under the Quick mix trademark are considered optimal for use in the domestic climate. The solution tolerates low temperatures, as well as sudden temperature fluctuations, high air humidity. There are compositions for warm and cold time span. The most famous among the latter is Quick VIX VK 01. In the line you can find products for materials with different water absorption, density, as well as mixtures with thermal insulation characteristics.

Sand-cement mixes with the presence of modifiers from the brand BROZEX also enjoy the confidence of buyers. They are characterized by ease of preparation, durability,moisture and frost resistance, as well as qualitatively fill both horizontal and vertical seams, demonstrating high adhesion. Such compositions are suitable for use only at temperatures from +10 to +25 degrees. Additionally, it should be noted that within 2 days after installation there should be no frost.

Among the mixtures with domestic production, it is possible to distinguish products under the brand name "Rusean". Most of the compositions made on the basis of M-150, they are characterized by increased strength and weather resistance.

Professional are considered "Shakhty mixtures" with enhanced performance properties. However, due to their greater viscosity, their use may seem difficult in the absence of the necessary skills.

Also popular are cement-sand mixtures “Osnov” and “Hercules”, which demonstrate resistance to shrinkage of buildings, and increased indicators of stability. Due to the variety of options for mixtures, they are suitable for the construction of different types of masonry.

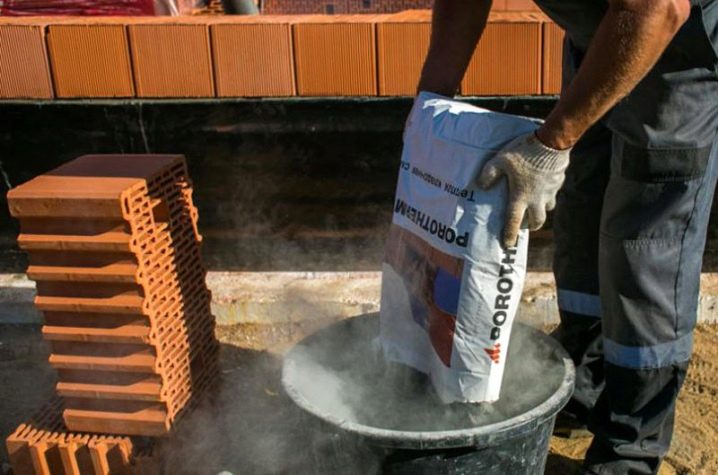

For block construction, it is better to choose a warm eco-friendly blend Porotherm tm.

Tips and tricks

For the preparation of masonry mortar it is necessary to add the volume of water that is specified by the manufacturer. Mixing the solution should be done only with a mixer. In its absence, you can use a special mixing nozzle on the drill. It is unacceptable to try to mix the composition manually, because it will be difficult and may cause the desire to add more water, and the violation of proportions in the finished solution leads to a change, more precisely, the deterioration of its technical properties.

The stated characteristics have only high-quality original products. It is not recommended to buy unnamed mixes from unknown manufacturers. Before buying, it is better to ask the seller to show a certificate of conformity to make sure that it is not a fake that is being purchased.

Pay attention to the terms and conditions of storage. Most masonry mortars are suitable for use within 12 months from the date of manufacture, provided that they are stored in sealed original packaging protected from moisture and direct sunlight.

Since the viability of the diluted solution does not exceed 45-60 minutes, it is necessary to dilute the amount of the composition that will be used during this time.Frozen, but not lost the viability of the solution can be re-knead. It is forbidden to add water and other liquids.

Review of masonry mortar "Shakhty mixtures", see the following video.