Scope of concrete contact

Application areas of concrete contact are extremely diverse, but not everyone knows what it is and what qualities it possesses. In order to make a reliable opinion about this primer, as well as to figure out where it is used, you need to familiarize yourself with many of the nuances that distinguish this type of soil.

Special features

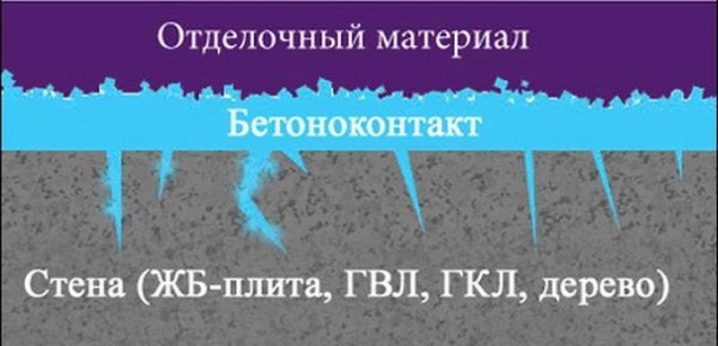

Primer concrete contact is designed to bond between the surface is absolutely incompatible. It can be used to attach new ceramic tiles to old ones, for example. It improves the adhesive characteristics of smooth surfaces, so that the adhesive can hold other coatings on them. And this applies not only to smooth materials, but also to all others, from concrete to wood. Contact between the material covered with concrete-based primer and the new coating will be optimal.

Such indicators are achieved due to the improved technical characteristics of the mixture.It consists of some additives that greatly increase adhesion, which makes the surface slightly rough to the touch after processing. This is the first feature: the surface will not be smooth, it will be rough. This will lead to the fact that dust will stick to the treated wall, so you will have to act quickly.

Unlike other primers, colorless concrete contact is not very convenient to use. This is due to the fact that the surface must be soaked with this solution evenly and well, and when processed with a transparent composition, the bald spots and empty places will not be visible. Another thing - colored soil: uneven color is visible immediately, and after drying you can correct the layer, “rolling” with a roller on the problem areas again. So, a higher quality surface finish is evident.

Concrete is safe for humans. When working with the mixture is required to take only basic precautions, and that the neglect of these rules will not lead to disastrous consequences. As a rule, even once on the skin, the composition does not cause allergic reactions, and simply removing it with water and soap is enough. Another thing, if the human body is prone to all sorts of allergies. Then it is best to work with gloves and fully enclosed clothing to avoid the possible occurrence of complications.

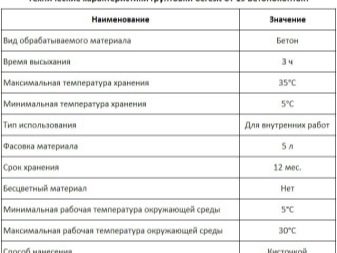

Another feature of concrete contact is the ability to preserve the surface, protecting it from the negative effects of moisture or low temperatures in the winter. At the same time, the mixture itself does not tolerate negative temperature. Thus, only treated areas can be cooled in a dry state. When storing the concrete composition, the temperature must be from +5 degrees to +30 degrees, otherwise it will lose its properties, stratify and become unsuitable for work.

Therefore, it is worth taking a responsible approach to the selection, making sure that the material was stored in the store under proper conditions.

Concrete is different from all other primers and drying speed. In order to "grab", it takes 2-4 hours, depending on the manufacturer, and full drying is achieved in two days. Therefore, you will have to work quickly, otherwise dust will stick to the treated walls, and the treatment will need to be repeated. However, too much hurry is not worth it. It is necessary to allow the layer to dry for the specified time (usually it is 2.5-3 hours), only after that apply a new layer of concrete contact, plaster or glue.

It should be borne in mind that betonokontakt designed exclusively for interior work. Do not use it outside - this is a common mistake. When wet, most concrete mixes simply go off with a film, so that they will not be of much use. It is much better to use ordinary primers designed for outdoor use. There will be more sense, and less money spent.

Mixing concrete compositions from different manufacturers should not be. Despite the fact that they all have similar characteristics and ingredients in the composition, practice has shown that mixing different solutions gives a negative result: some of the properties declared by manufacturers are lost, and concrete contact is not much different from ordinary primer.

Advantages and disadvantages

If you collect all the specific features inherent in concrete mixtures, you will be able to make lists of their positive and negative qualities. So, The advantages include certain characteristics:

- Deposition rate Since the material can be applied with a whole list of tools, it does not take much time. However, it is necessary to consult the instructions on the package. It indicates whether it is possible to use any of the tools for working with this composition. For example, some concrete-contact primers cannot be applied with a roller, but only with a brush, while others are “friendly” with all the tools.

- Drying speed. Unlike all other soils, concrete contact has a record setting speed, which was already mentioned a little earlier.

- Waterproofing quality. When applied and dried, the concrete contact forms a moisture-proof film, thereby improving the overall waterproofing. If the composition of deep penetration is chosen, then it additionally protects the surface from water vapor. For example, such a high-quality moisture protection is needed before making a self-leveling floor.

- Efficiency. Mix consumption is calculated per square meter. So, the average is about 350 ml. According to approximate calculations, a standard 10-liter bucket will be enough for processing 3 square meters.m square.

- Long service life. Manufacturers claim that the coating can last for 80 years. Since the material has appeared relatively recently, it has not yet been possible to verify this theory.

- Versatility. This means that concrete contact is used for processing various internal surfaces. For example, it can be applied even if the old finish layer has not been removed. Betonokontakt perfectly keeps on oil or acrylic paint, whitewash, drywall, concrete, iron or wood surfaces and even glass.

- Antiseptic properties. With the help of a concrete-contact solution, it is possible to prevent the appearance of fungus, mold and other microorganisms on the surface, which will have a positive effect not only on functional qualities and durability, but also on aesthetics.

- Security. As a rule, all kinds of chemicals and toxic additives are not included in the composition, but mainly natural components are used, so that it can be considered environmentally friendly.

The abundance of advantages nevertheless does not exclude the complete absence of shortcomings, which include some provisions

- Scope of application. Thus, it is rational to use concrete contact only indoors, not outside the building, because when used in outdoor work, some of the declared qualities will be lost. It is necessary to pay attention to the purpose of the mixture: some of them are intended only for working with certain materials (for example, concrete).

- The limited temperature conditions. It is impossible to store or work with a concrete-contact primer at low temperatures. The temperature should be from +5 to +30 degrees, which creates certain inconveniences. Moreover, the deterioration of concrete contact during freezing does not speak in its favor.

- The need for preliminary surface preparation. To achieve a good result, it is necessary to properly clean the surface from dust and dirt, remove fragile places. In fact, the statement that the mixture can be applied to the existing finishing layer turns out to be a lie, because the old surface must be durable.

- The need for strict adherence to instructions. Depending on what material is bought, what company released it, the technology of its application varies.What remains unchanged is that water cannot be added to the finished mixture and operated at temperatures below +5 degrees. Only if you follow all the requirements stated on the packaging, you can achieve a guaranteed result.

- Proper application. It is necessary to take into account the nuances of surface treatment. For example, at a time it is necessary to process only such a site, which will be immediately further developed. Of course, if you immediately treated the entire wall with concrete contact, then nothing terrible will happen. Just need to re-impose the composition, which will lead to unreasonable cash costs. This situation is one of many that should be borne in mind when starting work.

- Cost of. Many find the price for such a primer above the average, but this is justified by the properties of the material. No other soil can guarantee that it will be possible to combine the two materials with incompatible characteristics. Of course, there is a cheaper alternative - installation of textile mesh with the subsequent application of putty, however, no one has been using this method for a long time, because it is more laborious and time consuming.

It is much easier to buy concrete contact and just cover the surface with it.

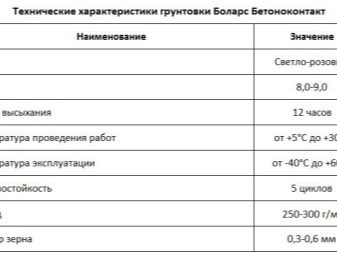

Specifications

All concrete contact soils have similar technical properties, which determine their strengths and weaknesses. By the way, in many ways they overlap with the advantages already listed, so it makes sense to list them briefly:

- high drying speed;

- increased moisture resistance;

- profitability;

- durability;

- reliability;

- safety for humans and animals.

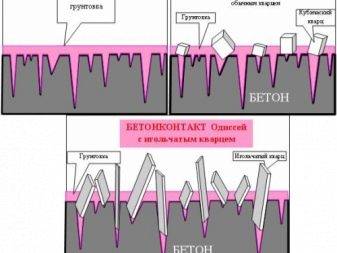

Concrete-contact solutions are available in two fractions: 0.3 mm and 0.6 mm. The first option is used when preparing the surface for puttying, the second - before plastering. The composition includes quartz, depending on the size of which this or that type of fraction is indicated. It is worth noting that there are two types of quartz in concrete contacts: needle-like and ordinary.

- Ordinary have a standard cubic shape. They are used in most formulations. It turns out that the faces partially close the microcracks on a smooth surface, improving the adhesive properties.

- Needle quartz flat. They fall into microcracks, penetrating them almost to the very base.Thereby, the concrete-contact primer is held much better on the surface, and the new coating is fixed more reliably.

The difference between the usual soil, the composition with the usual quartz and needle is visible in the second image.

As a rule, concrete contact is made on an acrylic basis, and this is due to its resistance to moisture. Acrylic is not a water soluble material. Usually, the primer layer is not removed, but if such a need arises, it will be necessary to use special solvents.

Concrete contact primers are usually available in white, but there are bright pink. By the intensity of the color it will be noticeable how evenly the layer of material is applied. To check the degree of dryness of the material, you will need to use a spatula. If you lightly hold on the surface, you will immediately see whether the concrete contact is dry or not. So, after 2-3 hours after the application on the spatula, there will be no more traces.

Please note that the setting speed depends not only on the characteristics of the soil, but also on the conditions in the room: humidity, temperature, drafts.

The release of concrete-contact compositions is consistent with the standards of GOST. So, it is necessary to focus on the group 28196, as well as 52020-2003, which regulate the production of concrete mixes.

Packing depends on the form of release of concrete contact. On the market you can find ready-made mixtures of consistency of liquid sour cream or powdered products, which in the future must be independently diluted with water according to the instructions. You can find ready-made primer in buckets and cans of the following masses:

- 1.3 kg;

- 3 kg;

- 5 kg;

- 6 kg;

- 10 kg;

- 12 kg;

- 20 kg;

- 25 kg;

- 40 kg.

Application area

The main purpose of concrete contact is to increase the adhesive properties of materials in which these characteristics are much lower than the average. As well as the solution helps to preserve the surface, protect it from sudden changes in humidity as a result of changing temperature regimes. In addition, it protects the surface from the appearance of mold fungi and other microorganisms on it, whose vital activity affects the appearance and functional component of the surface not in the best way.

Concrete is suitable for processing the following grounds:

- solid monolithic concrete;

- aerated concrete;

- foam concrete;

- brick;

- cement and cement plaster;

- gypsum and gypsum plaster;

- gypsum fiber sheets;

- drywall;

- cement particle boards;

- tongue-and-groove plates

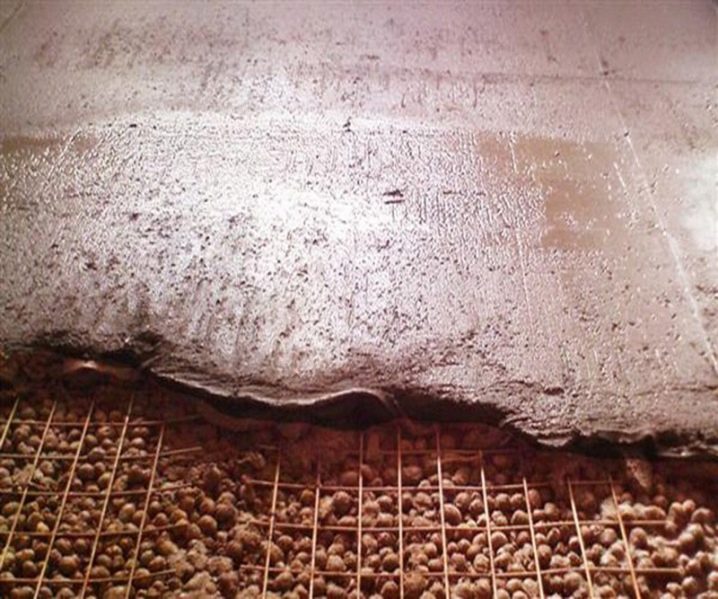

Basically, concrete contact is used when the base cannot absorb moisture normally, and precisely because of this, its adhesive properties are practically at zero. We should also single out the cases when the ceiling surface is treated. Then only primer concrete contact is used without subsequent plastering. Concrete is used immediately before the application of the finishing layer. You do not need to process it on top. It is enough to apply glue or decorative plaster at once - in a word, a finishing layer.

It does not matter what kind of surface is treated - floor, ceiling, wall. Concrete contact is equally suitable for the installation of the ceiling, and for the design of the base under the self-leveling floor or concrete screed. Most often, of course, the walls are treated with concrete contact, if the repair is done only for cosmetic purposes, and you don’t want to waste time, money and money on dismantling the old coating. Does not play the role and complexity of the architecture.No matter what will be processed - a ledge, a niche, a multi-stage architectural structure.

The primer concrete contact penetrates equally well into the surface, ensuring an optimum degree of adhesion even on protruding elements.

The production of special formulations applied for some materials has been adjusted. The advantage of choosing such a solution is that during the development and production all the specific features of this or that coating were taken into account, and the ratio of ingredients in the concrete-contact primer was selected in such a way as to ensure the maximum degree of adhesion. Concrete contact soils for concrete foundations are very popular.

There are special concrete contacts for sale outside the building. If there is no emergency, it is better to abandon their use - the effectiveness of their use is greatly exaggerated. If such a primer is really needed, you need to look not for universal concrete contacts, but intended exclusively for outdoor work. Only such a composition will give a more or less good result.

Subtleties of use

So, the necessary conditions for the use of concrete contact is a preliminary surface preparation. To do this, you must perform a certain sequence of actions:

- First you need to remove dust from the surface with a brush or brush. Here dry processing is applied: your task is to assess the scale of the contaminants, and also to remove everything that is possible without resorting to complex cleaning. In the future, this will greatly simplify wet work.

- Using water and a cleaning agent, remove all dirt from the surface. Pay attention to the thoroughness of the work. There should be no contaminated and dusty areas, stains.

- Clean the surface with clean water again. Removes all traces of detergent. The base should be washed, so to speak, before the squeak.

- It is necessary to leave the surface until completely dry. Mixing with water, primer concrete contact loses some of its properties, so it is better not to risk it.

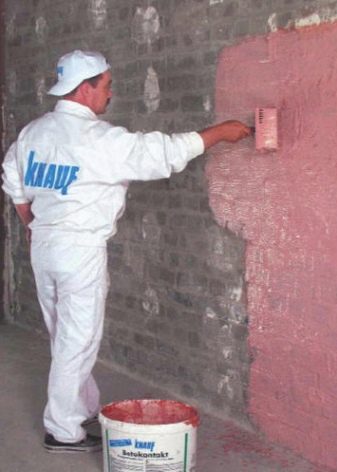

The procedure of applying the composition does not present any particular difficulties. You can use the following toolkit for this:

- paint brush;

- roller;

- brush or wide brush with thick bristles;

- spatula or mallet.

One of these tools must be applied to the surface with a thin layer. Please note that the surface should initially be completely dry.y. The same applies to cases where concrete contact is applied in two layers. So, the first one must dry out completely before you can proceed to re-treatment.

The best option for applying primer concrete contact is a brush, because it allows you to vary the intensity of the layer at will, but many people prefer the roller because of its ability to completely “give” the recruited composition, thereby rationalizing the flow of funds.

After the surface has been treated and the applied layer is even, it is necessary to wait until the primer is completely dry. This may take 24-48 hours. This is not about grasping, but about complete drying. So, after 3 hours to apply the finish layer is still too early. Testing the readiness of the wall is done easily: the material on which is carried out with an ordinary metal trowel, easily moves away. If this happens, the concrete contact is not dry.

However, it is also impossible to wait too long.This is fraught with the fact that dust and other contaminants will stick to the surface treated with concrete contact, as a result of which the adhesive properties will suffer greatly. To avoid this, all activities should be carried out according to the time given in the instructions on the package. A win-win is to treat the surfaces in the evening with concrete-contact primer, and in the morning proceed to the rest of the finishing work.

Tips and tricks

Professionals are willing to share some useful tips that will help to perform work on the application of concrete-contact soil quickly, simply and efficiently.

- In accordance with many recommendations, the surface before applying concrete contact need process ordinary primer. This will strengthen the surface in case there are flaking areas somewhere inadvertently. And also it completely removes dust from the surface, allowing concrete contact in the future as well as possible to adhere to the original base.

- Do not be guided by the price of the composition. It is not an indicator of quality at all. However, it is worth remembering that too cheap mixtures a priori cannot be of high quality,since the raw materials used in the production of concrete products are quite expensive. The best solution is to get acquainted with the reviews on these or other compositions, as well as buy soils only from trusted manufacturers.

- When calculating the material consumption, keep in mind that it depends not only on the characteristics of the mixture, but also on surface reference. Porous bases require a larger amount of concrete contact, the application of several layers, while for a smooth surface one thin layer can be sufficient. So, the least mixture is used when priming plasterboard structures, since drywall has practically no pores on the surface.

- Before buying, be sure to ask availability of quality certificate for goodsas well as the conditions under which the mixture was transported and stored. It may be that when you come home you will find that you have bought low-quality products. It is not uncommon for concrete contact to simply stratify, with all the additives responsible for improving adhesion at the bottom. Putting such a solution on the wall, it is impossible to get an even layer.

- It is not always possible to determine the quality of products "by eye", but the presence of lumps in the mixture is a clear indication that you have low-quality or expired goods. And in fact, and in another case, it can not be used. It is best to return the concrete contact to where you bought it. For this reason better to buy a primer in specialized hardware storesand not in the markets, as in the second case the seller of a poor-quality product may quickly disappear and you will lose money.

- Works with concrete contact without problems can do it yourself. They require neither special professional knowledge nor preliminary training. However, if you need everything to be done promptly, it is best to entrust the finishing to professionals. They will be able to process the entire room at a time, which is simply beyond the power of one person.

Manufacturers

Buying goods from a trusted manufacturer that has proven itself in the market is already half the success. Below is a list of the 10 most sought-after firms in the market that are trusted and respected by builders not only in Russia, but throughout the world.

- Axton. The company offers a wide range of dry mixes, intended for subsequent personal preparation. If you follow the instructions, you will receive high-quality concrete contact with a low consumption (about 300 g per 1 sq. M) and a high drying rate (it “sets” in about 2 hours at room temperature).

- "Plitonite". This brand belongs to the German concern Mc-Bauchemie. The latest production technologies and the excellent quality of the raw materials used guarantee the high quality characteristics of the concrete contact produced by this company. Sold in ready to use form.

- "Optimist". One of the few companies offering a truly worthy concrete contact for outdoor work. But the disadvantage is that the drying time of this material is twice the rate of "setting" of all other similar products. Here it is 4-6 hours.

- "Bolars". This manufacturer produces a high-quality product, which greatly increases the adhesion of subsequently applied compositions with a base. Betonokontaktny solutions are suitable for preparation for putting plaster, cement or polymeric means.Sold in finished form.

- Kreps. The company manufactures dry mixes. A distinctive feature is that it offers concrete mixes, suitable for different rooms: bedroom and living room, bathroom and kitchen, as well as for external work.

- "Founds." Concrete primer from this manufacturer deserves special attention. This is due to the fact that it has special cold-resistant properties, and also tolerates extremely high temperatures. So, the temperature range is 120 degrees - from -50 to +70 degrees. It is worth noting that there are no more analogues with the same characteristics on the market.

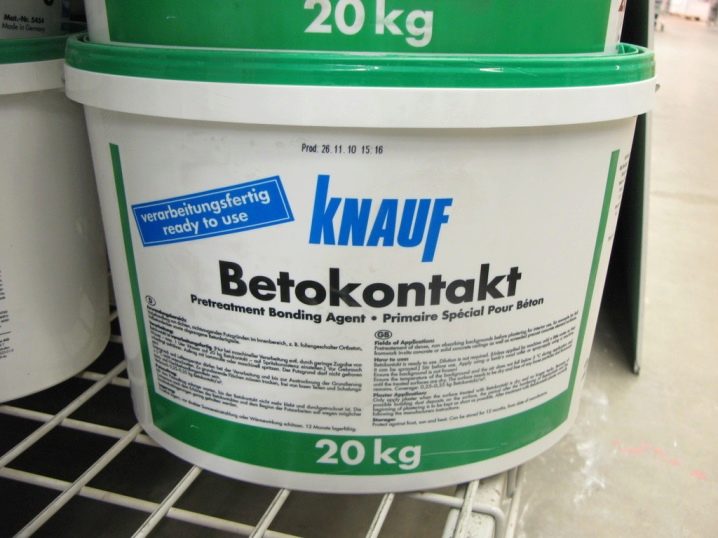

- Knauf. This manufacturer has proven itself. He has long been offering his products, which is characterized by consistent quality and reasonable price. This also applies to concrete contacts. Specifications remain at an average level: setting time - 3-4 hours, consumption - about 350 g per 1 square. m

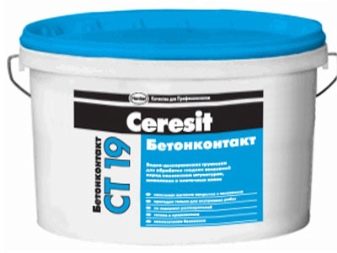

- Ceresit. Concrete from this manufacturer applies to those that can not be applied with a roller. Here it is imperative to use a brush. It is worth mentioning that this material has a water-dispersion base, and not acrylic.For this reason, it should not be allowed to mix with water: the concrete-based primer from this brand is water-soluble.

- "Miners". Concrete has a wide range of applications. It can be used with a variety of bases ranging from old tiles and ending with the preparation of monolithic concrete for subsequent filling. The material has the highest drying speed, which is 1.5-2 hours depending on the room microclimate.

- Odyssey 2000. This manufacturer from Russia for many decades engaged in the implementation of various paints and varnishes, the quality of which is beyond doubt. The same applies to concrete contact primers. In particular, this company was the first to start using compositions with the addition of needle quartz instead of ordinary ones, therefore its developments can rightly be considered one of the best in the field of primers.

Reviews

Feedback on the use of various concrete soils mainly positive. This is because With the invention of this material, it became easier to repair. Now you can quickly update the appearance of the room without the need to completely clean the paintedoil paint wall, for example. After all, the dismantling of this paint causes a lot of problems, as it cannot be washed off with ordinary water. It became more convenient to revet concrete walls, since there was no need to construct a gauze bandage so that the plaster could hold on at least somehow.

Some negatively respond only to the fact that there is a need for additional financial costs for this type of primer. This is especially worried for those who have to handle porous walls, for example, brick.

How to use concrete contact, see the next video.