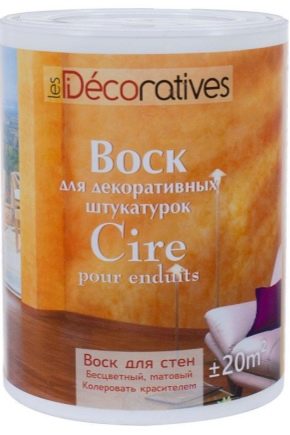

Wax for decorative plaster

Today, interior decoration of an office or home living room often includes the pretentious owner’s desire to emphasize a particular feature of the atmosphere. At present, the use of decorative plaster is most popular in the interior decoration. She allows to realize almost any imagination of the designer. Such finishing is often supplemented with the application of special wax.

Features and purpose of wax

When the walls are trimmed, the process should in no case be short-lived, no matter how hard the time is. The use of plaster for walls implies the fact that the shades of colors are already defined, since this finish should not be colorless. Finishing here plays an important role.To maintain the perfect appearance of the coating, wax mixtures are used, including those with protective functions.

Wax gives a layer of decorative plaster on the walls shine, favorably emphasizes the structure. It is applied so that the Venetian and other types of finishing mixtures correspond to the type that the contractor conceived or the customer wished.

Many believe that this is available only to real masters of their craft and artists. However, in fact, everything is much simpler and more prosaic.

Many craftsmen "fill their own value," telling of the incredible complexity of waxing to "sell their services more expensive." The reality is that if you work carefully and adhere to technology, it is quite possible to do everything yourself. It is quite simple, although there are some nuances.

Applying wax is a subtle operation. The thickness of the layer (it can be called not a layer, but a film) plays a special role, so you need to be very careful.

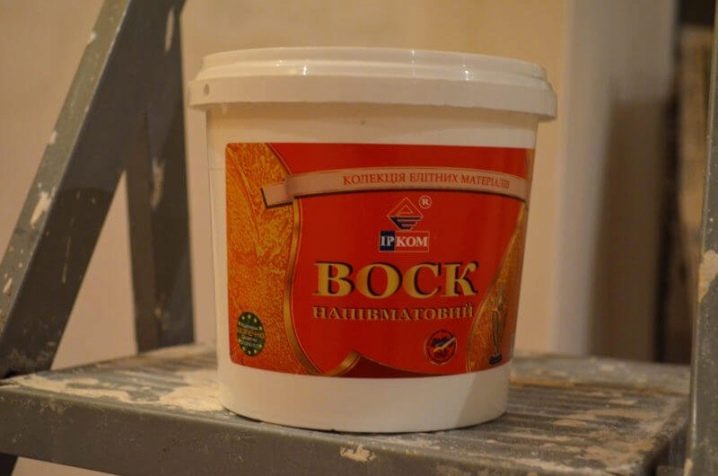

The mixture based on wax can be composed of both natural and synthetic components. It may seem strange, but natural components may be formulations based on natural beeswax.If we talk about synthetic products, then it can be options with artificial wax. It is more durable, but, as a rule, makes the surface slightly matte. The solvent in a mixture of any kind is liquid, but the rule of adjusting the layer thickness should be followed - use an alcohol solvent.

If the wax is too thick, it is recommended to slightly warm it (but not over an open fire), after which water is added not more than 3% of the total volume of the mixture. Then you will need to wait about a week or so for the wax solution to complete the blending process before use.

Types of plaster mixes

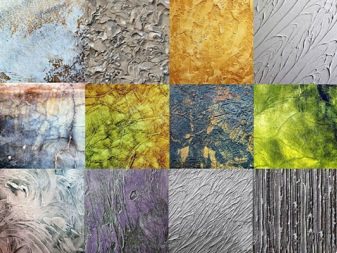

Consider some types of decorative types of plaster, so that there is an understanding of what needs to be achieved, using wax mixtures to create a beautiful effect.

- Structural type Gives the surface grit. It can be considered the simplest. The effect of graininess is achieved when mica or quartz is added.

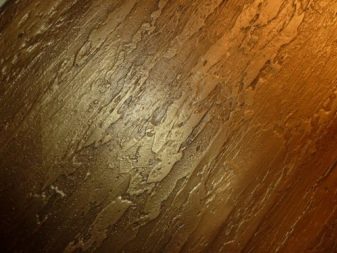

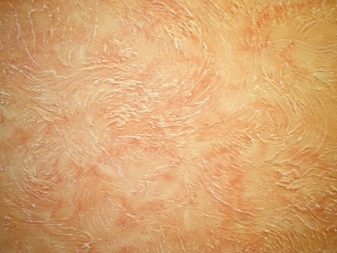

- Textured type. It gives the coating the effect of "ancient stone", "skin", "silk". All effects are achieved through the use of special tools and adherence to special techniques.Includes resin inclusion, as well as wax mixtures, fixing the picture.

- Venetian type. One of the most spectacular types, giving the surface of the walls a visual similarity to a marble surface. Venetian type of plaster coating is known since the days of the ancient Romans. Slaked lime, marble flour and other components are added to make a similarity. With the help of emulsifiers, the degree of thickness of the mixture is achieved.

Wax varieties

Wax coatings offered by manufacturing companies today can be divided into the following types:

- Wax gels are applied on dense and solid layers of plaster.

- For a porous plaster surface, a liquid solution is perfect. It has a higher degree of absorption than gel wax and better protects porous plaster on the surface.

- Substances, the main component of which is natural wax, have water as their basis, which gives the surface a gloss after application.

- Compounds based on acrylic synthetic components may include polymers, which increases their mechanical stability, surface protection and service life.As a rule, they give the surface a matte finish.

- The transparency of the wax coating makes decorative plaster particularly attractive, so the use of transparent wax is more common here. Ordinary coatings are covered with colored variants, giving the bases different tones, as well as the “silk surface effect”.

- Wax mixtures with shades of color are suitable for use if there is a need to change the color scheme of the finished plaster walls or change / correct it. Trading networks of the corresponding direction offer mixes for every taste, therefore the choice remains for the performer.

- Specific shades of wax impart a special depth to the surface imitating the stone, and can also provide a silky effect. When silver, bronze or gold powder is added to the transparent mixture, an impressive effect is obtained, since after the wax layer hardens, the wall surfaces will begin to overflow with reflections of the corresponding metallic color.

- Optimal is the use of a transparent wax mixture, or its yellow shades.Most often, yellow waxes are used when creating the surface in the Moroccan style.

- Shades of silver and bronze colors made to mix with their own hands. They are most often produced by combining natural wax with a powder of the required color. The degree of saturation of shades will depend on the amount of powder that is added to the finished composition. The wall will play with modulations in the rays of the sun, on it the details that emphasize the special unique features of this coating will be perfectly visible.

When there is a preparation of the composition, remember - in color terms, the liquid looks more saturated. When it dries completely, there is a slight change in shade. When deciding to cook the wax yourself, you should knead it in slightly dark colors. They are used if there is a purpose of giving imitation the texture of a stone.

If the mixture based on wax contains only natural ingredients, they are usually diluted only with water.

Application Tips

The beginning of the waxing process should be only after the plaster has completely cured:

- Dust is removed from the surfacewhich can cover it during freezing.Best of all, if the dust is vacuumed up - it will give the maximum degree of efficiency.

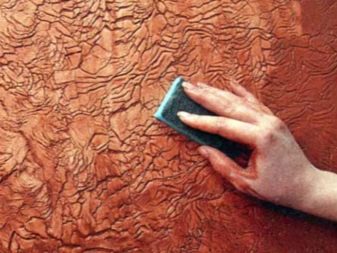

- If according to the instructions it is recommended to apply the composition with a trowel, and experience with similar tools is missing, to achieve a uniform layer, most likely, will not succeed. In this case, it may be advisable to use a spatula made of rubber. It will help in obtaining the most even surface. But do not get carried away. It is recommended to start from small areas, gradually capturing all large sections of the walls.

- In the next step, soft tissue is taken. The wax mixture is rubbed into it until the gloss or even the sheen of the treated area appears. This is the most important point of the entire application process. As a result of these actions, the penetration of the wax mixture into the layer of plaster is ensured, and it can accept only a certain amount of it.

- All excess wax must be removed.

We advise you to remember that wax helps in concealing any flaws in the decorative coating, provided that it is done no later than 4 hours after its application. An overly thick layer of wax mass is removed either with a cloth,or using solvents based on white spirit.

There should be no joints / transitions on the wall, so they try to remove excess material at a time. Each wall should take one cycle to achieve a uniform and uniform structure.

Before purchasing a wax mixture, you need to know the exact dimensions of the treated surface., even with previous experience of application, since different compositions differ significantly in their consumption. Each surface has a different coefficient of porosity. The form of the composition will affect the coating process and so on. It can be argued that the average consumption varies from 50-80 g / m2.

How to make homemade mixes?

Wax composition can be prepared independently. The recipe is simple.

You can use the following components:

- various types of adhesives that are used with non-woven wallpaper;

- panel glossy varnishes;

- paints with silver shades of color.

The adhesive must be diluted in accordance with the manufacturer's instructions. Usually use this proportion: glue / varnish / paint - 1/1 / 0,5. The mixture (on average) consumes no more than 120g of the wax mixture per m2.Do not miss such an important point as the weighing of components.

Procedure:

- glue is first diluted;

- to dissolve it completely, you will need to wait up to half an hour

- after that add varnish and paint of the desired color;

- components are mixed until they reach the desired thickness of the mixture.

For how to make wax for decorative plaster yourself, see the next video.