Features improved plaster

To carry out a quality repair meeting all technological requirements and standards, experienced builders constantly improve their professional skills, studying new trends and developments in the field of construction and finishing works. Increased requirements for the technical characteristics and aesthetic properties of the finishing coating led to the appearance on the market of building materials of modified improved plaster and innovative methods of its application.

The possibility of using high-quality plaster by professional builders and novice craftsmen made the material in demand and occupy a leading position in the sales rating.

Special features

Observing all the technological standards and rules of wall finishing with simple plaster, it is possible to achieve a high quality of coating and prolong its operational period.The use of high-quality plaster eliminates the technical and physical disadvantages of the solution, as it is an improved version of conventional plaster.

Improved plaster is a modern and innovative method of applying a finishing coat., featuring high quality and enhanced performance, used to finish walls of brick and concrete.

Advantages:

- getting a smoother and smoother surface;

- no unpleasant smell;

- high drying rate;

- mechanical resistance to cracks and chips;

- high percentage of sealing;

- no damage when in contact with moisture;

- resistance to aggressive environmental influences;

- the presence of refractory properties;

- preservation of the structure and all properties with prolonged exposure to high temperatures;

- the ability to immediately carry out finishing work (paint application, putty, wallpapering);

- minimum material consumption to obtain a flat surface with a thickness of 15 mm;

- compliance with established technical standards and technological standards;

- low percentage of error.

Disadvantages:

- high price;

- use only high-quality expensive components;

- high degree of labor intensity;

- obligatory presence of professional skills and experience;

- the inability to use in children's rooms and recreation areas (environmental incompatibility);

- the presence of contraindications for use by novice masters indoors.

Specifications

The use of improved plaster due to the use of special technologies and innovative method of applying leveling finishing material. Work with such compositions is carried out only in cases when medium or high requirements are imposed on the working surface with the need to obtain perfect smoothness.

The composition of the improved plaster includes high-quality basic components of simple plaster (water, sand, cement) and additional ingredients that improve the structure of the composition (modifiers).

The obligatory addition of PVA glue to the solution increases the adhesion of the cement base and sand.

For the preparation of high-quality mixture used a smaller percentage of sand than in conventional solutions.The process of mixing components begins with the combination of water and glue, only then is the gradual addition of the remaining ingredients. The structure of the composition should resemble liquid rubber, be elastic and viscous.

The technological process allows the replacement of a small part of the cement base with gypsum, but not more than 25%. The use of gypsum reduces the cost of the solution and improves its interaction with glue.

To an improved type of finishing material, SNiP imposes a number of mandatory regulatory requirements.according to which strict quality control is conducted:

- deviation difference during installation - no more than 2 mm;

- sand fraction for soil - no more than 2.1 mm.

Scope of application

The use of such plaster allows you to create a flat and smooth surface, protect it from moisture, fire, climatic changes and adverse weather conditions, improve thermal insulation properties.

Due to high quality characteristics and operational advantages, improved plaster has a wide range of applications.

The material is used both for interior decoration of premises for various purposes (apartments, offices, industrial buildings), and for facade finishing works. It can be:

- finishing of facades from a stone, a brick, concrete or a tree;

- design of various elements of the decor of the facades of buildings made of various materials;

- interior wall and ceiling decoration;

- finishing window openings and trim frames of complex shapes;

- application as a base coat for decorative plasters and tile coating.

Application technology

High-quality plaster has found its application in the finishing of various surfaces, but most often it is used on brickwork and concrete foundations. Improved plaster allows you to create a perfectly flat surface with high performance characteristics without the installation and installation of the frame. The scheme of applying the solution depends on the required quality of finish, the number of coating layers and the features of the technological process.

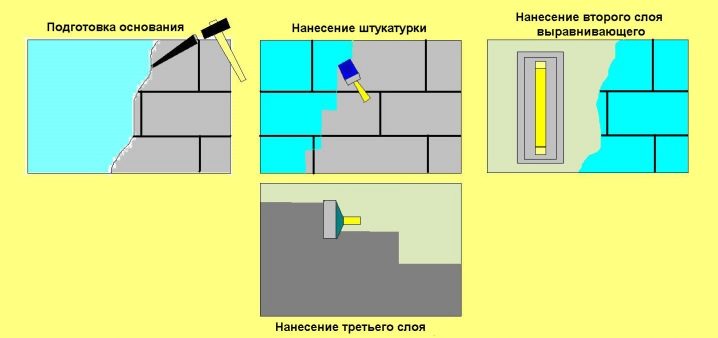

Proper preparation of the preparatory stage - the key to quality and fast execution of finishing works.

Preparation includes several points:

- cleaning the surface from dirt, residues of old materials and flaking coating areas;

- alignment of the surface with a height of deviations of no more than 2 mm;

- drawing on a working surface of soap solution.

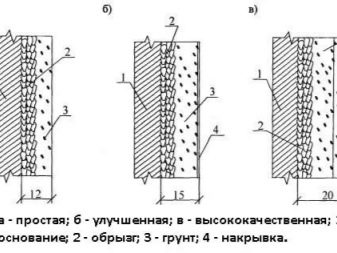

The work of applying plaster consists of three stages:

- applying a base layer with a thickness of not more than 2 cm;

- accurate and fast execution of the finishing covering (covering) up to 1 cm high;

- holding grout.

Carrying out finishing work with the use of improved plaster, it is necessary to consider some of the features:

- The average thickness of the spray should be no more than 5 mm. It uses a liquid solution, which is distributed over the surface without leveling.

- A thick solution with a filling of sand particles of 2 mm in size is applied to the soil. It is recommended to apply one coat no more than 10 mm thick.

- Coating is carried out with a layer no more than 2 mm thick. The size of the applied sandy filler should not exceed 1 mm.

- The thickness of the plaster should not be more than 15 mm, which allows it to be applied to complex surfaces with difficult relief.

Application of repeated layers of the solution is possible only after complete drying of the previous coatings. Reinforcing mesh is used to increase the thickness of the plaster. Metal mesh prevents cracks and fractures on surfaces made of metal, wood and foam concrete.

Tips

For high-quality and fast execution of the tasks, novice builders should take into account the advice of experienced craftsmen:

- Before starting work, the surface must be treated with a deep penetration primer (this increases the adhesion of the plaster to the working surface);

- Addition of PVA glue to the solution increases the strength and elasticity of the mixture, prevents cracking and separation of the applied material from the working surface, maintains a uniform coating structure, improves moisture impermeability;

- the presence of glue in the solution allows to increase the thickness of the formed layer and eliminate the use of construction mesh to increase the reinforcement;

- re-use of excess solution is prohibited (due to the formation of lumps and changes in the structure of the mixture);

- for determining irregularities on a brick or concrete surface, a rule of about 2 meters should be used;

- Before using a building material, it is necessary to check the date of manufacture, brand, weight and standard;

- strictly follow the manufacturer's instructions.

Independent production of the solution will significantly reduce the estimated cost of the work.

In the manufacture of the mixture, experts recommend that you strictly follow the following recommendations:

- for the manufacture of the mixture it is necessary to use ingredients such as water, sand, cement, PVA glue;

- not cement, but plaster is allowed;

- the addition of a plasticizer ensures the plasticity and viscosity of the solution;

- connection with water should be carried out in a large container;

- if necessary, increase the amount of glue;

- components need to be connected gradually, taking into account the consistency of the solution, its functional characteristics and difference from other compositions.

To obtain high-quality coverage, control over compliance with SNiP and GOST standards should be carried out at all stages of the work:

- at the preparatory stage - quality control of the mixture and the degree of cleaning the base, checking the temperature level of the working surface and its humidity;

- at the stage of work - determining the level of quality of work performed and the percentage of errors;

- during the inspection and final acceptance of the base - quality control of the adhesion of the solution and the working surface.

Before starting work, it is necessary to carefully study the properties and characteristics of the finishing material, as well as the reasons preventing the use of conventional plaster. The use of environmentally friendly components and fillers simple plaster can not only improve the performance of the coating, but also significantly reduce the cost of finishing material.

Competent and professional approach to the choice of ingredients, as well as the study of all norms and technological standards - the key to a quick and high-quality implementation of the tasks.

For more information on improved plaster, see below.