Features plaster mix

Anyone who has ever made repairs on their own knows what a plaster mixture is. However, an unenlightened buyer, faced with the task of choice, will not understand the difference between dry plaster and plaster mix. Let us dwell in detail on the plaster compositions, let us designate their features, types, scope and selection criteria.

Specifications

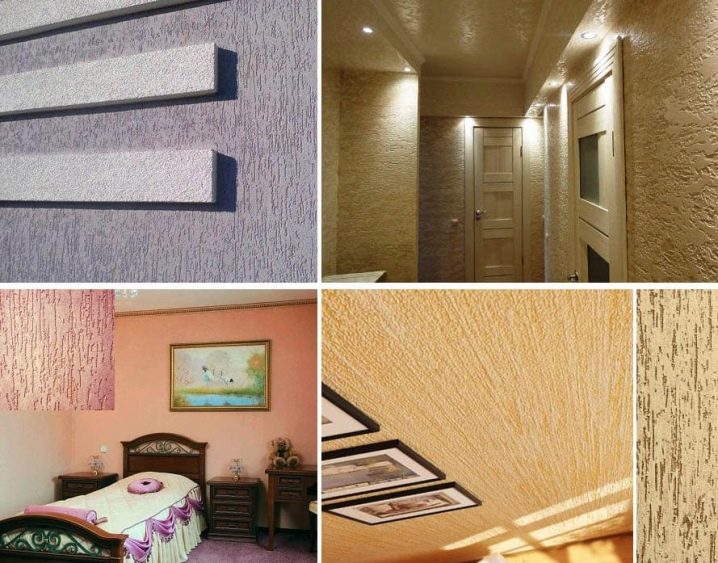

Plaster mix is a special material based on binding elements and various additives. Depending on its purpose, it is suitable for indoor or outdoor use. In addition, such compositions are granular. This factor determines the type of plaster. It is the composition and size of the fraction that determines the use of the plaster material as a starting or finishing coating.

Externally, the starting material is different coarse texture and often unsightly source color of raw materials. It is used mainly for decorative or finishing coating. The task of such raw materials is to prepare the base for finishing. For these reasons, the composition has a low cost. The finish version is different from the starting counterpart. Its structure is soft, creamy and plastic.

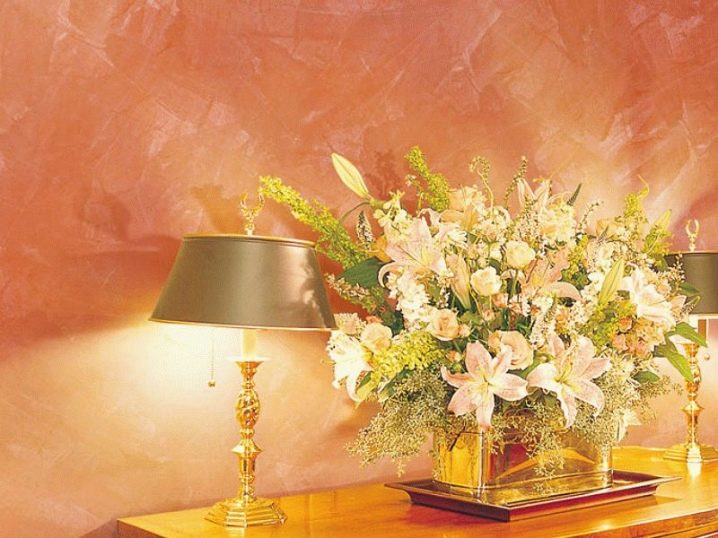

The cost of this type may vary significantly. This is especially noticeable if a separate category of decorative coating with a certain effect is necessary (for example, a bark beetle, a fur coat, a Venetian, a silk one).

The main distinguishing feature of plaster from dry plaster is the fact that dry plaster is commonly understood as plasterboard sheets. The mixture is not a material with a clearly fixed form. It is applied on the prepared base, stretching over the surface in a uniform layer. It does not need fasteners, like dry plaster, it is not glued. The structure includes all the necessary components that provide a high level of adhesion. The type of mixture of different brands may vary shade.This is reflected in the final color of the coating after drying.

If necessary, you can always buy a version of the base white. This is what they do when plastering is a preparatory stage for the subsequent surface finishing. Decorative coatings on the basis of the finished solution can have coloring. However, the color palette of tones of the finished solutions is small.

In case of need of change of color it is necessary to add color of the necessary shade to plaster mass. This technique is used to decorate the surfaces to be finished when using finishing decorative plaster.

Advantages and disadvantages

Consider the features of the plaster based on its advantages and disadvantages. Highlight the main advantages.

- Plaster mix is a quality material. It is produced on modern equipment using new technologies. Due to this, it has high performance.

- This material aligns the base.. Depending on its type, it is possible to hide surface defects in the form of chips, hollows, cracks, holes.

- Such compositions are variable.. You can choose a mixture for the base of a particular type.The use of starting and finishing mixtures allows you to give the base the desired degree of evenness and colorful decorative background.

- These mixes possess anti-fungal impregnations.. They are a kind of antiseptics of bases, preventing the formation of a comfortable environment for the emergence and development of microorganisms.

- Such compositions eliminate the accumulation of moisture.. Due to their structure, they will eliminate the formation of condensate.

- They are heat insulation. Regardless of the type of plaster, it warms the walls. This is especially felt in the cold season.

- These compounds absorb sound. Even with a small thickness of the applied layer, they reduce the level of sound coming from the street or neighboring apartments.

- They strengthen the foundation. During operation, they do not crack, in most cases do not fade. Decorative coatings do not shrink during drying and are not deformed.

- Thickness of the applied layer is possible.I. Based on the peculiarities of the base, it is possible to apply plaster with a layer of 1-5 mm.

- The composition includes additives that increase the time of the life cycle solution. Virtually every compound is reinforced with an additive to increase adhesion.

- Such materials are resistant to fire.. In addition, they are durable and designed for long-term operation.

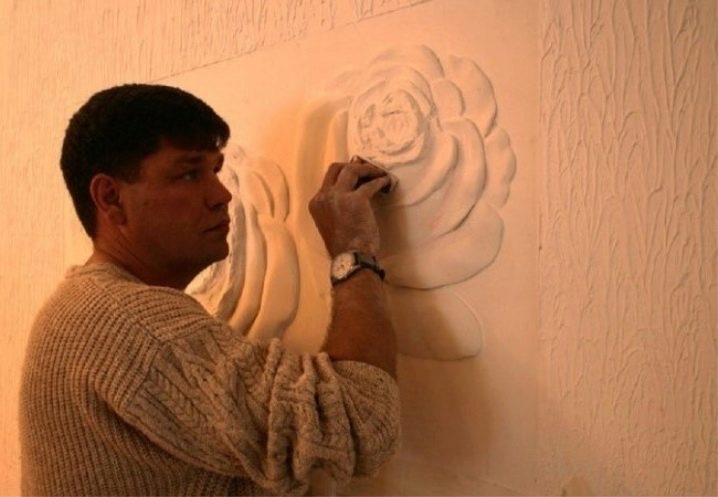

- Some varieties involve working with tiled material.. Others allow the decoration of the surface elements of stucco from the bulk.

The main mass of plaster coatings does not contain any harmful impurities.. They can be used in any room of the apartment and even the home of allergy sufferers. The line includes anti-radiation varieties and plaster insulation. In addition to them, manufacturers produce products with an acid-resistant composition.

The addition of liquid potassium glass allows the use of such plaster in areas where negative effects of aggressive vapors are possible. Virtually all types of mortar can be applied with a plastering bucket. This factor allows you to save up to 40% of the mixture and apply it on the base with a uniform layer in a short period of time (consumption is 50-60 cubes per hour). It is possible to simplify the execution of the relief pattern on the surface of the plaster.

Highlight the disadvantages of plaster.

- Not every type of this material is suitable for finishing rooms with a high coefficient of humidity.

- Some types of plaster mix are cold. Others need additional finishing plastering.

- With a large layer of deposition (more than 1 cm), deformation of the coatings (especially vertical ones) is not excluded. Sometimes this non-compliance with the technology leads to the formation of cracks.

- Some varieties of individual brands do not meet the stated characteristics, differing in low viscosity.

- Some types of coatings are not resistant to abrasion. In the process of cleaning, they will gradually fade. Others do not withstand significant mechanical shocks.

- Textured coatings are difficult to maintain. Often they are difficult to vacuum, it is impossible to wipe with a damp cloth.

Kinds

The modern market of building and finishing materials is replete with a variety of plastering materials. Mixed brands are offered in various forms of release. Conventionally, the entire range can be divided into:

- dry building material;

- ready mix.

The first option is more in demand from professional builders and finishers.This is the composition of the powdery type, which is sold in packages of 25 kg or more. Before the working process, such a powder is diluted with water in the desired proportions indicated on the packaging by the manufacturer. The finished mixture is a variety that does not require adjustment. These are products in plastic buckets, which are applied on the plane immediately after opening.

There is a difference between the two species. The finished material dries faster, so working with him is easier for a professional master. In addition, such a plaster composition is worse stored and has a great value. It is convenient, but only for finishing small areas. For large spaces, its purchase is often impractical because of its high cost.

By composition

The composition of modern plaster mixtures has its own classification. It is this factor that plays a decisive role in the choice of material for specific needs, dividing the varieties into building and finishing options. The composition of plaster mixtures are:

- cement;

- gypsum;

- clay;

- calcareous-carbonate;

- calcareous;

- glue;

- polymeric.

Each type of plaster has its own characteristics.Cement-sand construction options are the usual cement mortars. They are particularly resistant to mechanical stress, durable and moisture resistant. Suitable for use in rooms of unheated type and on the street. However, in the process of drying give some shrinkage. The best representatives of such compositions are masonry materials.

- Cement-lime dry the varieties in the composition have fine sand. They are simple and convenient in work, elastic, vapor permeable, stand out anti-bactericidal properties, acceptable in price. Suitable for indoor repairs. In order to avoid cracking they have to be applied in a thin layer.

- Clay mixtures used for finishing sites exposed to high temperature (fireplaces, stoves, chimneys). To improve their quality properties in the composition include asbestos, lime and cement. By their properties, such plasters are environmentally friendly, eliminate the formation of condensate. For durability inferior cement analogues.

- Plaster Compounds considered to be universal plaster mixtures.They are the best leveling walls and ceilings, but not applicable for leveling the floor. Such mixtures are characterized by plasticity, they are hygroscopic, not suitable for finishing bathrooms and toilets. With constant contact with water, these coatings deteriorate rapidly.

- Glue plaster mixes necessary for fixing layers of insulation or waterproofing materials. They include cement, sand, specialized fibers and polymers. Use this material in the case of alignment of the walls with the laid grid. The disadvantage of raw materials is the high cost.

- Polymer plaster mixes include silicate, silicone and acrylic options. Due to the special components of such a composition, its noise insulation is improved, moisture resistance and fire resistance are ensured. Such compositions can be painted by selecting the desired tone. The disadvantage is poor ventilation.

Criterias of choice

Since the world of plaster mixture is limitless and has a lot of varieties, it is easy to get lost in it. When choosing a store should follow the step by step instructions.

- First ask the sellerwhere is the rack with options for the desired type of work (internal or external). Look at the manufacturer's brand. Well-known companies produce quality products. Decide in advance on the desired brand, for which you can get acquainted with the reviews of masters about it.

- Specify the type of material: the starting one prepares the foundation, the finishing one decorates it, the waterproofing has its own purpose. The fraction (particles) of them varies, take what you need.

- Look at the integrity of the packaging.. This will allow you to understand the conditions in which the material was stored. Sometimes this factor is the cause of poor quality goods. Especially important is tightness for plaster in buckets and cans.

- Pay attention to the volume of raw materials. The stock is desirable, but a substantial surplus will deteriorate due to the short shelf life (6 months). Pre-home calculate the required amount with a margin of 10-15%.

- Decide on the view. For decorative trim the best choice would be a dry mix of white. It is better stored, minimizes surplus.

- Look at the label. It must be specified GOST.

- Pay attention to the density: This is an important selection criterion.The higher it is, the greater the likelihood of cracking of the plaster after drying.

- Read on the type of substrate base on the label.for which the mixture is intended. The universality of such compounds is relative.

- Look at the expiration date. If a week or two is left before its end, and the repair is just to be done, it is better to choose another option. Consider the pattern: the fresher the composition, the more demanded the material.

- Consider adhesion. Compositions based on quartz or sand stick to the surface better.

- Consider the type of room. The best composition is the one that says "for rooms with high humidity." To finish the facade you need an option that is resistant to adverse weather conditions. For laying tiles need a viscous adhesive composition. To decorate the walls or ceiling, take a mixture with additional additives for the desired effect (malachite, quartz chips, mother of pearl). For a foam block or plasterboard it is worth taking a plaster, for a wood cement-lime composition is better.

- Pay attention to the cost. Quality material is not cheap. The low price hints at a fake or expired product.

- Select your option, ask the documentation.. Quality material is always certified and has documents confirming its compliance with established standards.

- If you need to buy starting and finishing plasters, buy products from one manufacturer. Buy a water-based lacquer to the topcoat to prolong its durability. Choosing structural plaster, push off from the fact that its consumption will be more. A special relief is different texture of a fur coat.

- Look at approximate consumptionspecified by the manufacturer. Add a little to it so that the material is enough with the adjustment. To minimize excess consumption (at marriage and the performance of textured patterns), buy together with the plaster mixture the necessary tools for decoration.

Application area

The scope of use of plaster solutions is extensive. They are used in the construction and decoration of residential and industrial type buildings, as well as medical, educational type buildings. Such mixtures are especially common in the decoration of apartments. Depending on the composition, type and classification of plaster mixtures used for the walls and ceiling:

- polyclinics, laboratories;

- schools, libraries;

- cafes, studios, hairdressers;

- beauty salons;

- pools, baths, saunas;

- hotels, catering buildings;

- private buildings, country houses, summer houses (including with an attic);

- apartment buildings.

Based on the components and type of planned works, in the same object plaster mixtures can be used for internal and external works. Depending on the type of material it is used on different types of bases. This allows you to choose a material with special inclusions in the composition and additional properties that increase the life of the finished coating. Based on the characteristics of the composition, such mixtures are designed to work on the surface finish:

- concrete;

- wooden;

- brick;

- stone;

- drywall;

- mineral wool;

- aerated concrete.

Certain types of trademarks are available for styrofoam plaster, walls and ceilings of wet rooms. In each case, the manufacturer indicates the purpose of the products, indicating the type of basic plates (for example, for aerated concrete).

The best types of plaster mixes are decorative.They are used more often to finish the apartment, decorating the walls and ceilings of living rooms, bedrooms, study rooms, home libraries, corridors.

Manufacturers

Not every building material gets into the rating of high-quality raw materials. Even in the line of plaster mixes, the opinions of customers are contradictory. There are the following main manufacturers, whose products are more likely to be found on the market.

- Ceresit - a recognized leader in the production of plaster mixtures based on cement. Noted by a high score of professional craftsmen.

- Knauf - gypsum universal compositions-rotators "Rotband", providing the average thickness of the application. Recognized as worthy purchases.

- «Miners"- gypsum and cement materials, marked by conflicting customer reviews.

- «Volma"- gypsum plaster that does not require pre-filler.

- «Quick Mix"- lime fine-grained plaster of white color for application on plaster soil.

- Forman - cement plaster for interior and exterior use, providing manual and machine application.

- «Yaroslavl colors"- ready-made plaster for decorating prepared bases.

Each brand is ready to offer the buyer a wide range of products. The range allows you to find the approach to anyone, even the most demanding customer. For greater convenience, most manufacturers provide packaging weighing 5, 10, 25 kg. This allows you to get acquainted with the products in action.

Reviews

Consider reviews of plaster mixtures together impossible. Each species has its own characteristics, which emphasize buyers. For example, decorative plaster is the best choice according to buyers and craftsmen. Gypsum-based products simplify the work of masters, but at high humidity and leakage they are able to peel off from the base. Options with cement like buyers durability. Some new levelers do not justify the stated characteristics, users notice.

However, if we consider the benefits of plaster as a whole, this material has earned recognition in our country from ordinary people and professional craftsmen. This is evidenced by the numerous reviews that constantly appear on the pages of the World Wide Web building forums.Glue compositions allow coatings to be reliable and durable. This aspect is like both experienced craftsmen and beginners in the field of repair.

About this - in the video.