Glass cloth plaster net: purpose and types

The glass cloth plaster net is a necessary element when carrying out facing works, water insulation of ceiling and floor constructions, reconstruction of various surfaces. This product has reinforcing properties, strengthens the finishing layer by strengthening the frame, contributes to a better adhesion of coatings to the surface.

Main characteristics

Fiberglass mesh is made from thin filaments obtained by melting aluminosilicate glass. Special processing technology makes the canvas flexible, durable and elastic.

The main qualities of this unique material:

- resistance to aggressive, chemical, including acid and alkaline effects due to polyacrylic impregnation;

- high adhesion with plastering and putty solutions, mixtures on mineral base;

- resistance to pressure, shock, longitudinal and transverse loads;

- resistance to significant temperature changes;

- improvement of the performance of any coating and increase the period of its use.

Fiberglass does not bend and does not break, it can not be broken, the material is not susceptible to corrosion and decomposition, has maximum elasticity and is resistant to fire.

When purchasing it for repair in your home, you should make sure of the quality, and this is, first of all, a technical certificate that confirms the compliance of the plaster material with the necessary requirements.

The canvas is available in roll, has a length of 100 m and 1 m in width. It is convenient to transport it, and it is possible to apply, cutting off strips or sheets.

Benefits

The undoubted advantage of fiberglass reinforcement is its low weight, and therefore it is ideal for the ceiling. Since the web is flexible, it can be used even with uneven planes. Compared to metal reinforcing products, the glass fiber material does not corrode, so even after a long time, there is no rust on the coating.

There are also disadvantages to this product, and you need to know about them:

- during the working process, care should be taken, as small particles of glass dust can provoke allergies;

- It is difficult to work with the material alone, especially when finishing the ceiling - this can lead to insufficient tension of the web, its sagging and the appearance of air bubbles;

- primer and putty work because of the high absorbency requires a large amount of solution.

In addition, the construction grid has a very high cost. On the other hand, it is a necessary material, which greatly increases the life of any coating.

Fiberglass Varieties

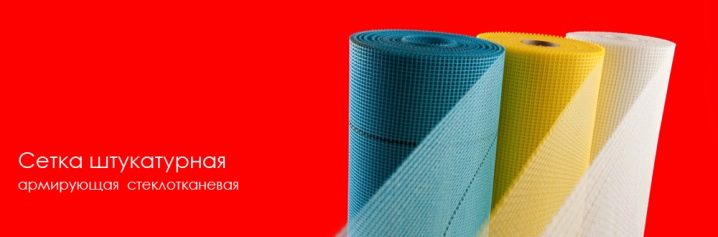

The main characteristic of glass fiber network is its density. Depending on this indicator, the main types are distinguished:

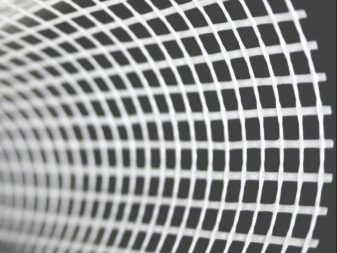

- Products intended for interior decoration. The painting option provides cell size from 2x2 mm to 3x3 mm, the density of the material - 50-60 g / cm3.

- Glass cloth (interior) product has a cell size of 5x5 mm and a density of 60-70 g / cm3. Basically, it is used for leveling bearing surfaces, finishing openings for windows and doors, waterproofing self-leveling floors, under plaster and plaster.

- Fiberglass cloth for the reinforcement of solutions for warm and self-leveling floors, paths, side walkways, stair steps and other structures with high traffic and, consequently, a large load. The mesh density is 100-120 g / cm3, the size of the cells of the web is the largest - 10x10.

- Universal glass cloth material - for the quality says the name. This option is the most durable - it can be used to reinforce walls intended for several thin layers of plaster, external and internal, its strength reaches 120-130 g / cm3, cells - 5x5.

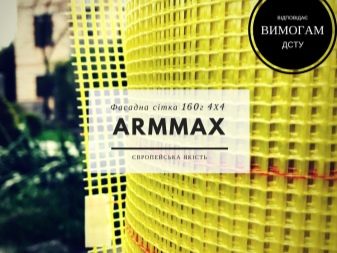

- Grid for puttying and plastering facadesfinishing them. The density of this canvas is much higher - from 145-160 g / cm3. Its cells are larger from 5x5 to 10x10 mm, depending on the processes. Usually, this is the treatment of external insulation with plaster, restoration, waterproofing of the foundation.

- Reinforced shell materialwhich reinforce the grounds under the tile to strengthen the basement. With a cell size of 5x5, the density of the product is 270-340 g / cm3.

As you can see, each product has its own purpose. Based on the thickness of the coating, the type of material is also chosen, since the reinforcement must be completely closed by slabs, panels or layers of plaster. The greater the density, the higher the resistance of the reinforced coating to various influences.

If the grid is of high quality, it must necessarily have a label on which the tensile strength and density are indicated, as well as its main purpose. When marking, for ease of selection, special symbols are affixed indicating methods of use: “H” for exterior work, “B” for interior work, a putty paint grid for wood, “A” for beech wood, reinforced strength is indicated by the symbol “ Wu. This facilitates the selection of products and gives an idea of the properties of the material.

When choosing it is important to pay attention to the type of polyacrylate impregnation, which depends on the color, as well as resistance to aggressive media. It is desirable that the indicators of strength and resistance to alkalis differ by no more than 50%. Products may have bright red, blue, white, yellow and other colors.

Scope of the reinforcing mesh

The plaster grid has wide application, its presence provides high-quality covering of surfaces with different types of coatings. During construction and repair, it performs the following tasks:

- strengthening of the skin when heat insulation and waterproofing is required;

- reinforcement of screeds, warm, as well as self-leveling floors;

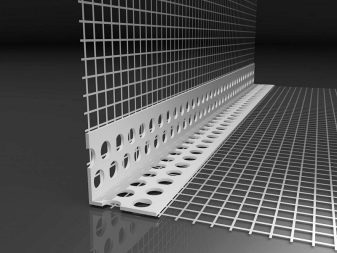

- facing of joints with gypsum-fiber sheet, panels of plastic, wood, metal, polystyrene foam, other blocks and plates;

- increase adhesion of finishing fragments, as well as plaster and plaster with bases of foam plastic, silicate brick;

- giving the optimal strength to the inner frame, in order to avoid peeling, cracking and other violations of integrity;

- increase the resistance of surfaces to mechanical stress.

Glass cloth material can be used for internal and external cladding, it plays an especially important role in large working planes, providing the possibility of uniform drying and deposition of putty and plaster, not allowing the coating to crack prematurely.

For external systems, strengthening of facade coatings, their decorative finishing, especially durable types of reinforcing material are used that can prevent damage due to significant temperature fluctuations, high humidity and other factors. In places of irregularities, seams and voids, the material performs the function of a frame, protecting the finish from partial destruction.

Installation of glass cloth mesh

It is better to mount the construction grid together, this will ensure maximum tension. For lower floors, you should use a dense canvas due to the large load and possible deformations.

All work is carried out sequentially:

- the preparatory stage is a thorough cleansing of particles of dust, small litter, dirt, the use of detergents is allowed;

- after complete drying, a primer is required for disinfection and better adhesion followed by a solution of putty or plaster, it is advisable to wait a day until it is completely dry;

- a layer of putty before reinforcement should be from 3 to 5 mm, the first plaster coating - no more than 2/3 of the total thickness;

- prepare the plaster solution in advance, prepare glass-fiber by cutting strips or sheets using simple scissors;

- Observing the proportions and recommendations of the manufacturer, an adhesive base is prepared from a dry mix for the mesh in a plastic container, and glue for expanded polystyrene will also work, you can stir it manually, with a drill with a special nozzle or a construction mixer;

- then it should tightly lay the reinforcing fabric on the surface, practically pressing it into the plaster layer;

- glue mixture is applied with a spatula or roller, rubbed, eliminating irregularities, folds, smooth the mesh and remove the leaked solution;

- the edges of the grid, when using cutting with whole canvases, should overlap each other by no less than 10 cm, the width of the sheet overlap varies depending on the complexity of the area being processed - this is usually associated with greater than expected material consumption;

- It is possible to apply the next layer of the finishing solution immediately or by letting the glue dry, it is important to ensure that the reinforcement does not protrude through the coating.

A feature of the use of plaster material is that it is impossible to fasten it to the surface with nails, metal screws and brackets, as is usually done with a metal grid.This causes rust spots on the surface of the coating.

Fiberglass mesh is ideal for any work, prevents shedding and cracking, so that the finish can maintain its original attractive appearance for a long time.

How to reinforce the putty glass fiber, see the following video.