Features of mosaic plaster

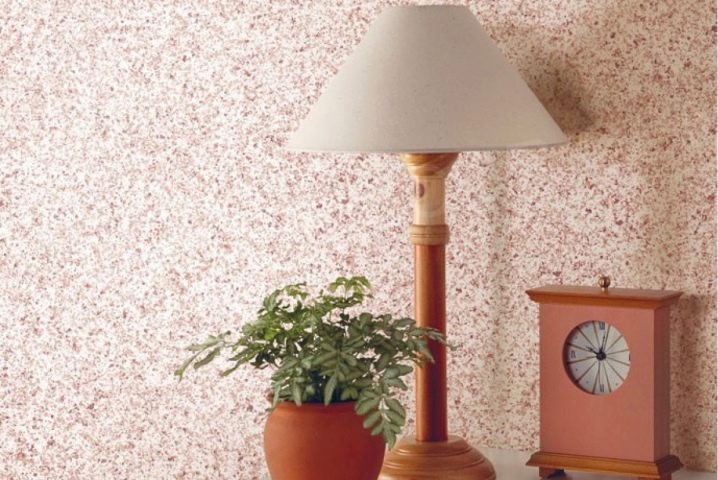

The choice of modern finishing materials is quite diverse. Every year thanks to the latest developments and technologies, more and more new products appear. Mosaic plaster appeared on the market of finishing materials relatively recently, but has already gained popularity among buyers. Due to its excellent technical characteristics, the material can be used to finish the interior and exterior surfaces of a building.

Material advantages

Mosaic plaster has many advantages and positive properties.

- The material has a high resistance to sunlight. Due to this property, the finish does not lose its original external data for a long time.

- A distinctive feature of the finish is increased resistance to precipitation, strong winds, moisture and temperature extremes.

- Strength.The coating is resistant to mechanical stress.

- Practicality. Plaster can be used to finish brick, concrete, cement and other surfaces.

- The surface, which is finished with mosaic plaster, is well ventilated. Moisture does not accumulate. This property of the material allows it to be used for finishing surfaces in rooms with high humidity.

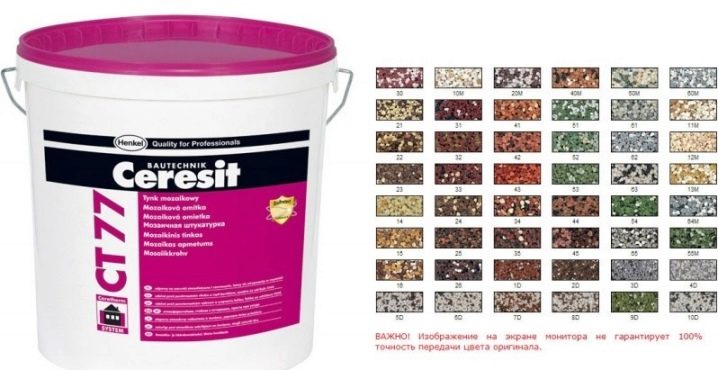

- In modern retail outlets you can find mosaic plaster of various colors. Thanks to this, you can create an individual, original interior.

- Durability. Thanks to its excellent technical characteristics, the finish will last for a long time.

- Maintenance and care of the coating does not require much effort.

- The material does not contain substances harmful to human health.

- To finish the surfaces using mosaic plaster, anyone can, even an inexperienced master.

The presence of a large number of advantages and excellent technical characteristics, plays a significant role for the popularity of mosaic plaster. In this case, we should not forget about the shortcomings of this material.

The disadvantages of mosaic plaster

Just like most finishing materials, mosaic plaster has negative properties.

Those with this material is not much, but when choosing finishes should be considered:

- When finishing surfaces made of metal, it is necessary to comply with certain conditions to avoid the appearance of corrosion. The surface must be pre-primed. You also need to opt for a special solution that does not contain water.

- In some cases, with certain damage to certain parts of the surface, repair will be impossible.

- The material has a high cost.

- Material based on various resins cannot be used for finishing surfaces insulated with glass or mineral wool.

- The services of a specialist in surface finishing imply additional financial costs.

The negative properties of this finish are not significant, and the advantages compensate them to the maximum. When buying a mixture should carefully examine all the properties and characteristics of the material.

Varieties of material

It should be noted that manufacturers produce several types of mosaic plaster.

They can be distinguished among themselves by some specific features.

- Filler. At production of material various fillers are used. The most common component is marble. Far less often, manufacturers use granite and quartz as an additive.

- The method of coloring particles. Manufacturers add particles colored in different colors to the plaster. Thanks to this, the mosaic acquires excellent decorative properties. For coloring particles using special paints. You can find materials of natural, natural color.

- Types of mosaic plaster are divided by the size of the particles in the material. There are four types of plaster: fine-textured, heavy-textured, medium-textured and small-textured. Therefore, when choosing the necessary finishes should pay attention to the characteristics of the material. Each mix pack contains detailed information about the type and quality of the material.

It should also be noted that the particle size affects the consumption of the mixture during the finishing work.Finishing will require a much larger amount of material if it contains large particles.

Today, plaster of marble chips becomes quite popular. It looks very expensive and original.

Depending on the application, the mosaic plaster is divided into three types:

- decorative mixture used in the performance of work on interior decoration;

- front;

- external mixture used as a finishing material for the treatment of the basement.

The composition of mosaic plaster contains a binder, in all types of mixture it is different.

Mixtures are divided into several types according to the type of component used in the production of the material.

- Acrylic blends. The main component in the composition of these mixtures is acrylic. The use of this polymer in the composition of the mixture makes the material more elastic. Acrylic blends are available commercially. Therefore, before use, it is enough to mix the solution.

- Mineral blends. As the main additive in the production of these mixtures are used minerals: gypsum, cement, lime.For the exterior of the building the most suitable mixture, based on cement. For the interior trim can blend any mixture. A distinctive feature of mineral mixtures is low cost. It should be noted that the finish, made with the help of these mixtures, has a high strength.

- Silicate mixtures. Potash glass is used as the main additive in the production of this type of plaster. Surface finish using this solution will not cause difficulties. The minus of these mixtures is rapid solidification.

- Silicone blends. The main additive in these mixtures is silicone resin. Silicone blends - a great option for interior decoration of the building.

Features of putting plaster

Putting putty on the surface occurs in several stages. All work, at each stage, should be carried out as carefully as possible, in compliance with all requirements. The end result depends entirely on this.

Surface preparation

Before you start applying the plaster, you must carefully prepare the surface. Removed all pollution, old wallpaper, plaster, and more.Then you should level the surface, close up all cracks, chips. For these purposes, you can use the starting putty. Further, after the coating dries out, it is necessary to check the flatness of the surface with the help of the construction level. After that it is necessary to prime the surface. The primer is applied in two or three layers. Each layer is necessarily dried.

Then, after drying the coating, you can begin to apply putty. Interior and exterior surfaces have their own nuances. Therefore, you should start to explore some of the details of the application.

Base finish

The quality of the execution of the exterior of the building depends on the air temperature. Therefore, all work should be carried out in the warm season and dry weather. Humidity also plays an important role.

After surface preparation, you can apply putty. First you need to prepare a solution, following the instructions and observing all proportions. Apply the mixture to the surface with a wide spatula, moving from the bottom up.

Next, you need to get rid of voids, for this you need to iron the surface with special graters.To create a pattern or pattern on the surface, you can use special stencils or simply roll the coating with a roller.

After that, the coating must be dried, and after about a day, the treated surface should be covered with a film. This will help protect the surface from precipitation and wind. After four days, the film can be removed.

Facade decoration

The process of finishing the facade is identical to the work on the base, but there are some nuances:

- There is no need to dry each layer of applied material.

- It should be borne in mind that the formation of angles involves the drying of each layer.

- The mixture should be purchased with a margin.

- The joints when applying plaster of different colors will be smooth and beautiful, if you use a special masking tape.

Also when performing work it is necessary to take into account the solution hardening time.

Interior finish

Performing interior decorating requires compliance with certain rules:

- The surface must be dry and thoroughly prepared.

- Finishing each room involves the use of a specific, special putty. Acrylic blend is used to finish the kitchen and bathroom.Gypsum mix - for the bedroom, living room and children's room.

- Putty is applied in one layer.

- The coating is thoroughly dried. The use of heaters to speed up the process is strictly prohibited.

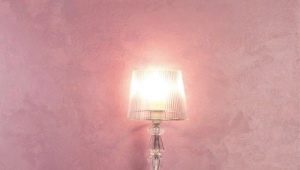

- After thoroughly drying the coating, the surface can be varnished.

Ceresit plaster is most often used for decorating walls, for example, a corridor. This decor will serve you for many years and will delight with its beauty.

Careful observance of all rules, proportions and instructions when working with mosaic plaster will help to achieve a quality end result and significantly save the family budget. You can cope with the process yourself, without resorting to the services of specialists.

How to apply mosaic plaster, you will learn in the next video.