Metallic plaster grid: the pros and cons of use

In the construction of buildings and the production of various types of finishing works, the use of metal grids is becoming more common. In order not to be mistaken with the choice of reinforcing metal mesh, you need to understand in detail all the pros and cons of its use. Knowledge of the features of the types of this material will help to make the right and informed choice.

Special features

Plastering facades of buildings or interiors using decorative compositions is one of the most common and cost-effective finishing options. A large variety of high-quality mixtures, differing in a variety of colors and textures, allows you to be confident in the attractiveness of the coated surface.

The only drawback is not very high strength of such a finish. To increase its reliability and durability, special reinforcing materials are used. Their use helps to eliminate the appearance of cracks during the inevitable shrinkage or movement of the new structure, improves adhesion bases and plaster mixes.

Strengthening structures are made from various materials, with the result that they acquire specific properties that determine the area of their application. Most often when performing plastering works are used:

- polymeric;

- plastic;

- glass cloth;

- metal mesh.

The choice of one or another type, first of all, depends on the expected thickness of the application of the plaster layer. You should also pay attention to the finishing materials and the composition of mixtures for decorative coatings.

Reinforcing metal mesh

Such material is the most universal reinforcing product. Its main functions are to strengthen and protect the plastered surface from mechanical damage. He warns of the possibility of cracking of the plaster layer due to a sharp temperature drop.The layer of rough finish is smoother and smoother, better prepared for the finishing work.

Reinforcement with metal mesh helps to further strengthen the not too strong and reliable structures.

In the production of building materials of this type using wire or metal rods. Depending on their thickness, the meshes are divided into the following categories:

- lungs;

- average;

- heavy.

Advantages and disadvantages

Today the range of plaster nets is very diverse. Steel constructions made of polyurethane, plastic and fiberglass are available. But the most popular are those that are made on the basis of metals.

This is due to the many features of their technical characteristics:

- Metal mesh has a special strength that helps it to withstand severe loads. If to level a large surface area it is required to apply a thick layer of plaster, then it is better not to save and purchase just such a material for reinforcement.

- Its use is possible when working on any bases and with different compositions of rough finishing solutions.

- Applying a plaster layer is not limited to its thickness. When working with thin or light bases, it is possible to apply a minimum formation of up to 20 mm. If it is necessary to level the differences in surface height levels on a vertical wall, then it is acceptable to apply the mortar with a thickness of more than 50 mm.

- In preparation for plastering a metal base, a reinforcing mesh can be welded to it, which will ensure greater reliability of the entire structure.

- To cut out individual pieces of a free configuration from a solid web, it is sufficient to use hand tools, for example, scissors for cutting on metal or nippers.

- Fixing such reinforcement does not require much time and effort. To create a strong connection with the base, it is enough to fix the grid in only a few places.

The main disadvantage of this type of material is its considerable weight. It can only be strengthened on surfaces capable of supporting the total weight of the metal mesh and finishing leveling compounds. It is not necessary to make reinforcement on surfaces of drywall or hollow brick.

A significant drawback can be considered the high cost of this building material, especially made of galvanized metal,possessing additional protective properties.

Types of reinforcing metal mesh

Reinforcement meshes are used both for plastering and for creating cement screeds or concrete pads. In their production, metal blanks are used, the thickness of which depends on the expected load on the lined surface. They differ in cell size. For plastering, lighter versions are used, the wire thickness of which does not exceed 1.5 mm and with a cell size of up to 30 mm.

The most popular sizes of products in accordance with GOST:

- 10x10;

- 5x5;

- 25x25 mm.

Manufacturers offer customers rolled and sheet reinforcing mesh. Each of these species is conveniently applied in its own way. When carrying out finishing work in areas with greater length, it is better to use rolled reinforcing mesh. This will require additional efforts when stretching and fastening, but will significantly improve the quality and appearance of the finished coating - it will be more even, since during the work a whole piece of cloth is used, characterized by the absence of seams and linings.

For artificial stone it is necessary to select a small size of the coating.

The technology of fixing the grid differs depending on the basis of the surface. It is enough to weld it to the metal with the help of a welding machine. If the grid is rather thin, then it is conveniently mounted on a wooden base with an industrial stapler, shooting large staples.

To fix the thicker reinforcement, you will need screws or nails. Reinforcing material can be attached to the foundations of brick or concrete with dowels with washers.

Currently on the market the most widespread several types:

- welded;

- woven;

- expanded metal all-metal;

- the chain-link.

Welded

This material is becoming increasingly popular among buyers because of the relatively low price and very high quality, it can also be used at any stages of construction or decoration. Most often, welded mesh is used for the following types of work:

- strengthening the foundation of the building;

- reinforcement of the walls of bricks and various blocks;

- when performing finishing works on the bearing surfaces;

- when installing the insulating layer.

It is made of metal rods of different diameters by welding them.In this case, the distance between them can be quite different. Net weight compared to other species is small.

Special attention should be paid to the material from which it is made. The use of stainless metals and their alloys is optimal, since the corrosion that has occurred leads to the early destruction of structures.

The main disadvantage of this type of plaster reinforcement is the weakness of the welds - they can cause tearing and rust. The smaller the size of the cells, the higher the probability of destruction, as these seams are larger. In addition, the grid, which has been stored in rolls for a long time, is deformed, which greatly complicates the subsequent work.

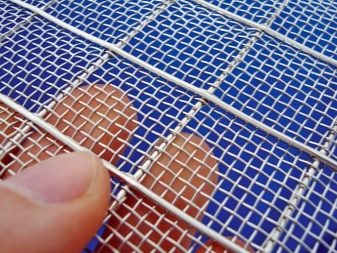

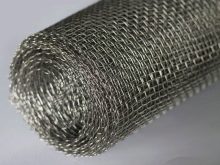

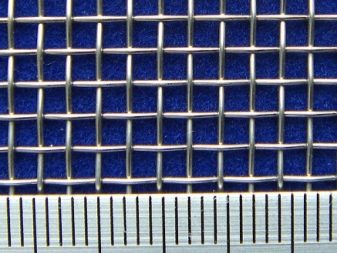

Woven

Metal mesh of this type is a versatile building material. It is a web of interlaced cross-shaped wires with the same cross-sectional size. It is produced on specialized weaving machines of stainless and low carbon steel, brass and other non-ferrous metals. May be used in the production of dyed steel filaments. Cells can be of different sizes and shapes, for example, square or rectangular.

In the construction of a large use of stainless woven meshmade of the same material. It is most often used as a reinforcement to prevent the appearance of cracks or sifting of bulk materials in the manufacture of sand and cement mixtures.

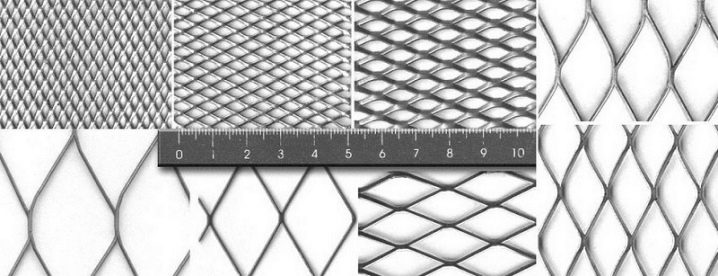

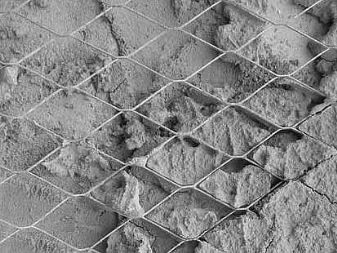

Expanded Metal Mesh

In construction markets, it can be found under the name "perforation" or the abbreviation TsPVS. This type of mesh is made from a single sheet of metal, the thickness of which can reach 2 mm, but plates up to 1.5 mm are most often used. Manufacturing technology consists in cutting openings and further stretching the material. As a result, cells are arranged in staggered order. This gives the finished product a special strength and flexibility. When one or several cells are deformed, the rest of the canvas is not subject to further destruction, but it is rather difficult to recover after storage in rolls.

Such a product is made without the use of plastic protection, which can cause its corrosion. The use of galvanized alloys significantly improves the anti-corrosion properties of the material,what is especially important in an aggressive environment of plastering compositions. There are no signs of rust in the finishing stages. Also significantly increased shelf life.

Depending on the base, its weight may vary. A distinctive feature is fire resistance and the ability to use on any surface. The ability to withstand heavy loads allows it to be used in the reinforcement of a concrete screed.

The main objectives of TsPVS:

- protection of the plastered ceiling and walls from mechanical damage and sharp fluctuations in air temperature;

- prevention of cracks due to technological violations in the process of finishing works;

- significant extension of the plaster warranty period.

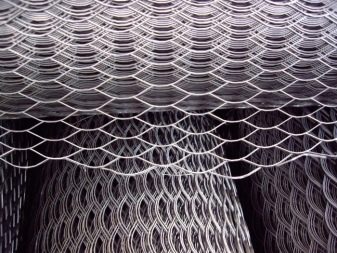

Chain-link

It is the most widely used and most popular material among the masters of the whole world. The use of this grid is not limited to its presence in fences - it is actively used as a reinforcing fabric.

For the production of chain-link wire is used round-shaped steel or stainless alloys with zinc.Improving its performance is carried out by applying to it a coating of polymers.

The manufacturing process consists in interlacing the wire in a special way. As a result, the mesh fabric stretches quite well and is very resistant to tears due to the absence of welds on it.

The disadvantages of chain-link include:

- complex installation due to the need for constant tension and frequent fastening;

- high price of the product.

The number of enterprises producing woven mesh is quite large, so you should pay special attention to product quality. To buy a rabbit masters recommend only from reliable suppliers who have a good reputation.

To date, none of the types of reinforcing materials are not represented in such a wide range as plaster meshes made from metal. Differing from each other in the method of manufacture, the shape and size of the cells, the thickness of the metal filaments of the web and the material of manufacture, they are a universal product in the construction market. Knowledge of the characteristics of each of them allows you to choose the materialoptimally suited for the realization of the most interesting building ideas.

For how to choose reinforcement mesh for plaster, see the next video.