Gypsum plaster: types and methods of application

For residential premises it is very important that building materials do not emit harmful substances. Among the putties the most environmentally safe is gypsum. Moreover, it is great for any decorative decoration and creates a favorable indoor climate.

What it is?

Gypsum is made from calcined gypsum stone, ground to a state of powder. This is an environmentally friendly natural material. Gypsum plaster can lay down a thick layer, so it perfectly hides the obvious defects of surfaces.

By itself, the plaster hardens very quickly, so for the convenience of the plaster contains various additives. It:

- small fractional fillers that facilitate the weight of the mortar, for example, polystyrene foam, foam glass or perlite;

- plasticizers that increase elasticity;

- lime or additives to give white;

- setting retarders.

Fillers also increase the insulating properties, increase adhesion. Gypsum plaster perfectly fits on brickwork, concrete walls, glossy surfaces, cellular foam concrete, expanded clay-concrete and aerated concrete. If the old layer of gypsum plaster is strong enough, but a new one can be applied on top.

Thanks to additives that make up no more than 10%, the plaster is easy to apply, plastic and lighter. This facilitates repair work and reduces their time.

This mixture is used to align the horizontal and vertical surfaces, walls and ceilings in rooms with normal humidity before finishing. It can also be used for sealing gaps, dimples, cracks. Due to its environmental friendliness, the mixture is suitable for residential premises, but is used only for interior decoration.

Special features

Plaster is made according to GOST 31377-2008.It is he who is responsible for the quality of the mixture, the main indicators of which include humidity, volumetric weight and grain size limit. At the same time, steam permeability by GOST is not regulated, although it is also an important technical parameter.

Specifications:

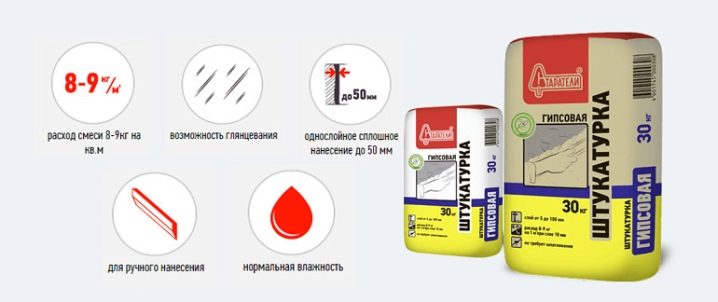

- maximum thickness without the use of reinforcing mesh - 5 cm;

- average consumption per 1 square. m - 8 kg;

- setting time of the solution - 40-60 minutes for manual application, 90 minutes for the machine;

- full drying of the surface - 3-4 hours;

- plaster strength set - 5-7 days;

- working temperature range - from 5 to 30 degrees Celsius;

- the proportion of dilution with water is 2: 1;

- thermal conductivity - 0.23 W / m * s;

- vapor permeability - 0.12 mg / pPa;

- adhesion to the surface - 0.3 MPa;

- frost-resistant;

- does not shrink;

- does not burn, fireproof;

- environmental friendliness - does not emit harmful substances;

- long period of operation.

Gypsum plaster has a high vapor permeability. It absorbs excess moisture from the air, and when the temperature rises quickly dries.

The condensate itself does not accumulate over the finish. If neighbors are flooded, the gypsum ceiling will absorb 90% of all water, preventing it from flowing down the walls or dripping onto the floor. If the water is clean, then the ceiling will dry out within a few days without staining.

The plaster is of high strength, does not shrink, and therefore does not form cracks and "web", at the same time it has a low mechanical strength - this surface is easily damaged. It perfectly masks obvious defects of surfaces, it can be repaired, it can be used to create decorative elements, relief and arches. If the wall collapses backwards, you can level it with gypsum plaster. With a layer thickness of more than 5 cm, additional surface reinforcement with a special mesh is required.

In addition to the advantages, gypsum plaster has disadvantages. These include low moisture resistance. The mixture is suitable for rooms with normal humidity, although there are special formulations with additional protection. Under the plaster plaster can not hide metal elements, such as staples, nails, screws, hooks, etc., as the absorbed moisture will contribute to metal corrosion.

Despite the pros and cons, gypsum plaster is great for finishing apartments. It has insulating and sound insulation properties, which is important in apartment buildings, and also improves the indoor climate.

Plaster has high adhesion to various materials and has wide application. Well fits on brickwork, concrete walls, aerocrete and foam concrete. It can be applied over the old gypsum plaster, provided it is preserved. After drying, it forms a uniform monochromatic coating.

Kinds

Basically, gypsum plasters are used for interior work, but recently mixtures for exterior have also been produced. The latter contain additional mineral and polymer additives that protect the facade from precipitation.

For interior decoration gypsum plaster mixes are distinguished by fraction: fine, medium and coarse-grained. Fine-grained contain in the composition of grated sand. This plaster needs to be applied only with a thin layer, no more than 1 cm, otherwise it cracks. The most running - medium-grained. They are universal, used everywhere in rooms with normal humidity for walls and ceilings, the maximum thickness of such plaster is up to 5 cm.

If it is necessary to impose a thicker layer, use a coarse mixture. They are used to repair door slopes, corners of rooms, make arches.

It is also found moisture resistant gypsum plaster for wet rooms. This is suitable for finishing kitchens, especially in the area of the apron, and bathrooms. It is undesirable to use it as a finish, but it is perfect for ceramic tiles or coloring.

Distinguish starting and finishing plaster mix. Starting is used to eliminate gross defects and deep cracks, it can set the texture, repair door and window openings, level the collapsing walls. The maximum layer of plaster is not less than 3 cm. Finishing plaster is used for finishing the premises, eliminates minor defects and requires puttying and glossing. Usually the layer thickness does not exceed 0.5 cm.

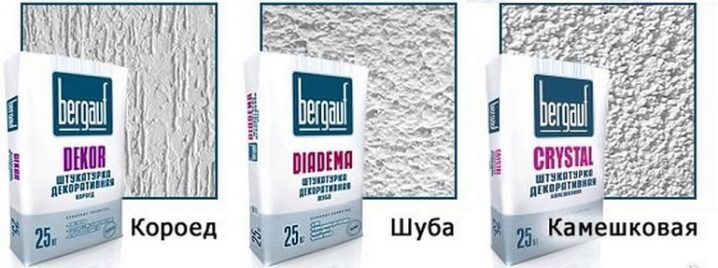

For finishing facades produce gypsum-polymer and gypsum-mineral compositions. Gypsum-polymer used for concrete and gypsum-concrete surfaces, as well as silicate bricks. Apply a thin layer, have greater strength and frost resistance compared to conventional plaster mixes, lightweight, but dries longer. Often, polymeric facade plasters have a relief pattern.Gypsum-mineral mixtures are more plastic due to mineral plasticizers, which simultaneously act as a binder.

Despite the additives that increase resistance to temperature extremes and atmospheric phenomena, gypsum plaster is not recommended to use as a finishing coating. All the same, it will absorb moisture and will eventually become worthless. The exception is regions with a dry climate and rare precipitation.

It is best to use gypsum-based plaster as an intermediate layer between the wall and the facing material, such as tile or stone.

There are mixtures and the method of application.

- For hand-made compositions contain less chemistry, the time of their setting is 40 minutes.

- When machine coating takes more time to work, so the composition contains special additives that increase the setting time by 2-3 times (1.5-2 hours). First, the master needs to apply the mortar to the walls, and then just start the alignment rule. Often, dry mixtures for machine application contain ground sand. It promotes better mixing of the mixture and smooth flow through the gun.

Most often, the plaster is found in white and gray, but you can find pink and beige. Lime-gypsum plaster has a white color due to the added lime. Also white color give titanium and zinc white in the composition. If necessary, a dye can be added to the solution, as long as it is combined with gypsum and additives in the mixture.

Gypsum plaster is packed in 5, 25 or 30 kg bags. It is important to pay attention to the expiration date, which does not exceed six months in tightly closed bags.

Which is better?

The choice is influenced by the list of required works. For door slopes and arches, it is better to choose coarse-grained putty, for walls and ceilings - medium-grained.

Foreign mixtures are more expensive, but there are domestic ones, which are no worse.

If you plan to machine the method of application, then the plaster should be appropriate. If it is necessary to purchase mixtures of different fractions, then only from one manufacturer with the same composition.

You can not mix mixtures from different manufacturers.. First, they may contain various additives that will not fit well with each other. All this will reduce the quality of the plaster layer.Secondly, they can have different shades, and the result will not look aesthetically pleasing on the walls.

It is worth paying attention to the composition. If chemical additives are more than 30%, then such a mixture will be more plastic, it takes longer to creep, it can crawl along the wall. For manual application, such plaster mixtures are not suitable, only for machine application.

Required tools

To dilute the mixture will require a plastic container with a volume of at least 60-90 liters. For water it is recommended to buy a bucket with a scale markup. It is better to mix it with a construction mixer or a powerful drill with a special nozzle. You can mix the solution manually, but this is very time consuming. Care should be taken to avoid air bubbles and lumps.

For putting plaster plaster it will be necessary:

- rectangular trowel, spatula or trowel for applying the solution on the wall;

- H-shaped rule - to align the plaster layer (about 2 m);

- trapezoidal rule or wide trowel - for trimming;

- sponge grater - for puttying;

- iron spatula - for glossing;

- metal shears, level, finisher, plumb line, tape measure, scraper - for preparatory work, installation of beacons and grid mounting;

- plaster beacons.

If you plan to work on the ceiling, then you need a plaster falcon.Grid and beacons on the ceiling do not install. The reinforcing mesh itself must be of galvanized metal or plastic so that it does not corrode.

Preparatory work

Before putting plaster plaster it is necessary to prepare walls.

- It is necessary to remove the previous coating, clean the oily stains, paint and wallpaper residues, dirt.

- If metal elements are present, for example nails, they should also be removed. If for some reason this cannot be done, then the surface must be treated with anti-corrosion compounds. For example, you can just paint.

- Wooden elements that hide under plaster must be treated with antiseptic.

- If there is a fungus, it must be cleaned, and this place should be treated with deep penetration fungicidal formulations.

- Further, it is recommended to gently tap the walls with a hammer. This is necessary in order to find weak unreliable sites. If there are deep cracks and potholes on the wall, then they should be fixed up. You can use the same plaster plaster, only to make the mixture more thick. The remaining defects will easily disappear during plastering.

Primer

The next important stage is priming. Weakly absorbent and smooth surfaces, such as concrete, must be treated with concrete contact. If the surface of the walls absorbs moisture well, for example, foam concrete, it is recommended to treat it with a special primer twice with an interval of 4 hours. This may be an acrylic primer with hydrophobic additives. If the walls are normally absorbable, then you need to use acrylic or styrene-acrylate primers of deep penetration.

Priming is a must. If the walls draw moisture from the solution, it may crack. Therefore, there may be several layers of primer.

Installation of beacons and installation of the grid

To regulate the thickness of the plaster can be installed beacons. They are arranged vertically in increments of 10-20 cm smaller than the size of the rule. From the corner of the room the lighthouse should stand at 20-25 cm.

If the layer thickness is planned to be more than 4-5 cm, then you need to implement installation of galvanized reinforcing mesh. Otherwise, the layer may recede under its weight. The maximum layer of gypsum plaster is 8 cm.

Before mounting the grid, markup should be applied in 40 cm steps.Holes are drilled at these points and dowels are inserted. In these places, the net is overlapped with at least 1.5 cm on stainless steel screws. The grid can also be planted on building glue, but not tightly pressed to the wall. If it is necessary to strengthen the door or window opening, then the grid is fixed diagonally. The desired area is cut with scissors for metal. Installation begins with any upper corner of the room. It should be fixed so that there is a gap of 3-5 mm between the wall and the grid. This is necessary so that it is located inside the plaster layer.

If the reinforcing mesh vibrates when touched or lies loosely, then it is additionally secured with a wire, which is zigzagted through the cells. There should be no sagging, otherwise air pockets may form and, over time, the plaster will lag behind the wall.

Making a solution

Now you can proceed to the preparation of the solution. On the package there is always an instruction. The dry mixture is diluted with water in a ratio of 2: 1, i.e. 2 kg of plaster is taken for 1 l of water. First, water is poured into the container, then the mixture is poured out. You need to mix them with the help of a construction mixer or a special nozzle for a drill. Next, leave it for 5 minutes to start the chemical additives, then mix well again.The quality of the mixture depends on the result of the application.

It is not necessary to mix a lot of solution at a time. It quickly sets in 30-40 minutes, so 20 minutes is given for application, and another 20 minutes for leveling. Therefore, it is better to prepare gypsum plaster in small batches. Do not "rejuvenate" drying solution with water. This leads to a deterioration in the quality characteristics of the mortar and a decrease in the life of the plaster layer.

The solution is sensitive to temperature - indoors it must be above 5 degrees Celsius, but below 30, otherwise it will dry out and quickly set.

Application technique

When hand-applied to the trowel, they collect the solution and throw it on the wall from bottom to top. The bottom layer should be thicker than the top. The rule then aligns the layer from bottom to top with oscillating movements from side to side. All irregularities, flaws and traces of the rule are removed with a spatula or undercut by a trapezoidal rule.

Periodically it is necessary to carry out a spatula on the previously laid plaster from the bottom up to avoid overflows. You can check the degree of dryness of the layer by slightly pressing it with your finger. If it is forced, then you need to wait for more.While the plaster layer has not completely hardened, the lighthouses are removed. The formed cracks are sealed with the same solution using a spatula.

If there is a reinforcing mesh, then the first layer of plaster should be more liquid, the consistency closer to sour cream. Plaster dial on a trowel and throw on the grid. When it dries, you can apply the next layer.

After 30-30 minutes, as soon as the walls dry out, it is necessary to moisten them with water until they become dull. After the wall, it is necessary to grind with a sponge trowel in circular motions in order to remove minor defects and expel plaster milk. The surface is smoothed with a wide spatula. This procedure is performed once, after it you can use textured paint and glue the wallpaper. It is not necessary to use any additional putty materials. If you plan to veneer with ceramic tiles, then this procedure can be skipped.

If you plan to paint the walls, then you need to do glossing. This procedure makes the walls smooth and is carried out 3-4 hours after filling, but not later than in a day. To this end, the walls are abundantly wetted with water, and then on the surface to hold an iron spatula with shaving movements.

Gypsum plaster can be applied with a machine. The equipment is expensive, so for a one-time repair it is better to rent it or invite a brigade of professionals. The machine consists of a solution tank, a hose with a pistol nozzle, a compressor, a power cable and a control panel.

The finished mixture is loaded into the container and fed under pressure through the hose. The gun is kept at a distance of 30 cm from the surface. Layers of plaster should overlap. After the surface is overwritten as well as with the manual method.

Tips and tricks

- Solution consumption per 1 sq. m depends on the thickness of the layer. So, for 1 mm of thickness there are 300 g of plaster. To calculate the total consumption, it is necessary to multiply 300 g by the layer thickness and multiply by the surface area. Be sure to lay an additional 10-15% for unforeseen consumption. If you plan to make decorative items, the flow will increase.

- Works are recommended to be carried out in well ventilated room., but without drafts and working heating devices. It is recommended to protect the surface from direct sunlight. After complete drying the room is recommended to be ventilated. The plaster itself dries in 3-4 hours, but it will gain strength even within a week. To completely dry, the layer will take 2-4 weeks depending on the thickness.Only then can the topcoat be applied.

- If cracks appear on the surface, This suggests an improperly prepared solution. Also cracking is promoted by forced drying. If the walls contain small pores, then this is normal. Worse if they are not present at all, which indicates low vapor permeability. Too large pores indicate that the solution was poorly mixed. To hide the defect will help the decorative layer of plaster.

- Shelf life of dry mix - no more than 6 months. It is stored in tightly closed bags. Gypsum perfectly absorbs moisture, so you should not buy opened packages. If there are lumps in the mixture, this indicates improper storage of the material or its poor quality. It is better not to use such plaster.

- Separate skill requires plastering the ceiling. So that the solution does not disappear, it is covered with sharp movements, leveled towards itself. In this case, it is best to carry out plastering with the help of a construction sprayer. The maximum layer thickness for the ceiling is only 1 cm. This is due to safety precautions.If a piece of plaster breaks away, it will not be able to cause serious harm to human health and life. With a very crooked ceiling, it is better to use other methods of finishing.

- Gypsum and cement plasters are often compared. And although the latter also contains lime, cement mixture is applied more often to external walls. It is more resistant to moisture and cheaper. But the gypsum is more environmentally friendly, it does not need to be additionally puttied, and after glossing it can be immediately painted.

- Gypsum plaster can be made independently. But gypsum quickly hardens, so diluted PVA glue (1% of the total solution), lime, citric acid or tartaric acid can be added as a plasticizer. You can also add the “Plast Retard PE” retarder. This is a special fluid that improves adhesion and increases the wear resistance of the plaster layer. With it, you can not use lime.

Famous manufacturers and reviews

Despite the general characteristics of plaster mixtures, the composition and quality of different manufacturers may vary significantly.

- Volma. Gypsum plaster of domestic production for premises with moderate humidity and minimal temperature difference.Used only for walls, used in restoration and decorative works. Cheap and not very plastic. The recommended thickness is up to 3 cm. The white color may have a beige or pinkish tint. Users note that the solution sets very quickly, failing to withstand the stated 45 minutes. This creates difficulties in the work. Represents the line of mixtures "Layer", "Plast", "Canvas" - for manual application, "Gypsum asset" - for machine.

- "Miners". Also products of domestic production, used for interior work on the walls and ceilings, filling joints, restoration of stucco. Moisture-resistant gypsum plasters are also available. According to user feedback, the solution of this brand is very plastic, it fits perfectly, it is easy to gloss. The maximum layer thickness is 5 cm. Of the drawbacks, only packing of 30 kg is noted, which is not always convenient.

- Knauf Rotband. Universal putty made in Germany, suitable for all surfaces and premises, including the bathroom. It is plastic, lays down perfectly and keeps, has a good consistence, quality, quickly and easily put.Among the shortcomings, users note a slight shrinkage and high cost.

- Ceresit. Another foreign brand known for its high quality. Gypsum plaster of this manufacturer can be used for internal and external works. Resistant to sunlight and precipitation. Impact resistant, easy to apply, allows you to make a decorative pattern with a roller. Of the shortcomings - the high price.

- Unis. This is a domestic production, which has several factories in different cities of Russia. Putty is lighter compared to other brands, plastic, does not form cracks, easy to apply, contains fine sand in the composition. Quality reviews vary widely. Users note that the solution does not mix well, forms lumps, plaster slips from the walls, dries for a long time, but is durable. The quality of the mixture, according to reviews, is highly dependent on the manufacturer.

- "Founds." It is applied only to dry rooms, has high vapor permeability, is easy to apply and flatten. Hardens evenly, forming a flat surface. The maximum layer without mesh is 8 cm.

- "Reference". A mixture of domestic production, the creation of which uses imported polymer additives. Solution well lays down, plastic, it can be applied with a thin layer. The recommended thickness is 0.2-3 cm. Users note the convenience in working with it.

- "Bolars". It is used for interior walls and ceilings. It happens white and gray. A mixture of high quality, plastic, plaster layer has a uniform shade. If the solution thickens, it needs to be re-mixed without adding water. Among the shortcomings, the high cost of this product is noted.

If you make a rating based on user feedback, then the first place will be taken by the gypsum plaster of the “Starateli” brand in terms of price and quality. The second and the third will divide Knauf and Ceresi

In the next video you are waiting for all the stages of working with gypsum plaster.