Features of facade plaster

The purpose of the facade plaster is to create a finishing coating of the exterior walls of the building. Features of this coating and a significant variety of mixtures on the market make this type of exterior finish one of the most popular with domestic consumers.

Special features

Almost any exterior walls can be subjected to facade plastering, ranging from traditional foam concrete to OSB-slab. The main thing is to choose the right mix. Modern varieties of exterior facade plasters are created on the basis of innovative technological developments, due to which they have significant qualitative differences from simple cement mortars that were used 15–20 years ago.

All types of exterior plasters have the following general features:

- the strength of the coating, which is able to withstand high loads;

- elasticity and high-quality adhesion to the base, subject to the application technology;

- high resistance to mechanical, ultraviolet, temperature and humidity;

- the ability to long-term storage in the form of a mixture or a finished composition;

- environmental friendliness, as the materials do not emit harmful fumes during operation;

- vapor permeability - plastered facades retain the ability to "breathe", thereby eliminating the creation of the greenhouse effect;

- a decorative function, the creation of attractive landforms and original options for durable exterior wall decor;

- ease of painting and care for the surface, as well as self-cleaning facade plaster mixtures;

- ease of coating.

Kinds

Among the varieties of facade plaster the most familiar to the domestic consumer is mineral plaster. This coating has the following advantages:

- this material has proven itself in the process of operation at low and high ambient temperatures;

- fireproof;

- the material "breathes", that is, is vapor-permeable;

- prevents the growth of fungi, suitable for the treatment of the cap;

- low cost

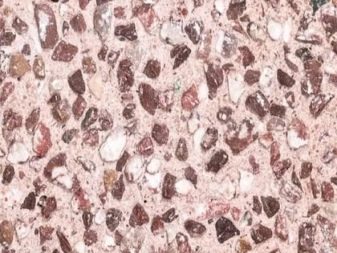

A variety of mineral plaster is terrazitovaya, a special character which is given interspersing mica, marble and glass. For decoration, pigment is added to the solution, an attractive appearance is achieved by phased cycling.

It has a cement-polymer mixture and warm vermiculite plaster at the base. The exfoliated mica-vermiculite acts as a filler substance responsible for increased warming characteristics. Due to this, the thermal conductivity of this coating is several times less than that of a conventional cement-printed mortar, and it is deservedly referred to as insulating plaster.

Among the cement plasters it is worth mentioning the perlite mixture, which also has enhanced insulating properties. Expanded perlite sand is used as a filler, which gives the composition a volume, reduces the weight of the finished coating and the load on the walls.

A significant inconvenience of using any cement plaster is the fact that it is produced in a dry form and requires, when diluted, experience and the use of a construction mixer.

In case of mixing errors, the composition may become unsuitable for operation.As well as considerable practical experience requires the application of such a coating. The cement-based mineral mixture is susceptible to vibration loads.

It has considerable weight, and also not everyone likes the narrow color range of the cement mixture, and painting requires additional funds. Service life is 10 years.

Acrylic plaster mix is produced on the basis of acrylic resin or aqueous solutions of various synthetic resins. It has the following advantages:

- has a high elasticity, due to which it is able to tighten small cracks on the surface;

- produced in the form of a finished mixture;

- has excellent adhesion with both conventional brick-concrete walls, and with foam and expanded polystyrene;

- vapor permeable coating;

- it contains bactericidal agents that prevent the appearance of fungus;

- does not absorb dirt and is resistant to high humidity;

- easy to paint with different colors.

Of the minuses, it is possible to call high electrostaticity, which is manifested in the fact that dust quickly adheres to such facades. Bright tones are subject to fading.

Acryl-based plaster should be applied by a professional, as it has a fast setting speed.

This composition has an average cost and service life within 15 years.

The basis for silicate plaster is a substance called liquid glass. This type of finishing material has the following advantages:

- the possibility of applying not only on concrete foundations and drywall, but also on the surface of insulation (expanded polystyrene and minplit);

- resistance to the appearance of cracks in the process of building shrinkage and negative atmospheric effects;

- high fire resistance;

- anti-static coating;

- the creation of a "breathable", but moisture-resistant coating that is easy to clean with water;

- sold in finished form, can be painted with colorant pastes;

- designed for a fairly long service life, which can reach 15 years.

In the event that this type of coating is applied to the mineral surface, no additional preparation is required, although primer treatment is necessary for other bases. The cost of silicate plaster is quite high, which is offset by efficiency when used, as the coating is applied in a thin layer.

Silicone plaster mixture is made on the basis of silicone resins, which are similar in their properties to acrylic resins. However, the silicone base has a higher elasticity, and therefore this type has the most pronounced covering characteristics, such as:

- tends to stretch on the surface of the wall;

- is the most durable of the existing in the domestic market today, the service life reaches 20-25 years;

- has high moisture resistance and is antistatic;

- has high adhesion, although it requires the use of a special primer;

- it has a very high resistance to aggressive environment (ultraviolet radiation, temperature drops, precipitation and other influences);

- Available in a huge variety of colors, which allows you to create a variety of colorful panels on the facades of buildings.

Gypsum mixture for outdoor work has negative reviews from professionals, which is associated with its low resistance to wetting, poor vapor permeability and the large presence of polymer components.

Which is better?

Deciding which mixture to choose for the exterior of the house,You can always find a balance of quality and economy. First of all, you should carefully consider the characteristics of various mixtures. Compositions for street work on aerated concrete, brick, mineral wool or polystyrene insulation, as well as for wooden surfaces are on the market today.

The easiest way to pick up facade plaster for gas blocks, bricks or walls of cellular concrete. In this case, you can apply all types of facade plasters, but do not forget to take into account the technological features of their application. Otherwise, the building owner is free to rely solely on his taste and the amount of the budget allocated for the design of the facade. Of course, silicone plaster mix will last as long as possible. It will cost quite expensive, but will not require replacement for 25 years.

Not any plaster mortar is suitable for wooden walls or OSB boards. Lime or gypsum compounds in this case are strictly contraindicated. Any silicone or silicate plaster will not work either. A classic will be the use of cement-sand mixture, also on wood applied acrylic facade coating.

Popular ventilated facades can be plastered with silicate, silicone and acrylic compounds. The main thing is to remember about the need to use appropriate primers and mesh, providing maximum adhesion to the base. To obtain the most attractive facades, it is recommended to use various options for decorative mixtures. The most popular are "bark beetle", "fur coat" and "lamb". With the right application, such a design looks unusual and attractive, and a well-chosen tinting adorns the structure. These mixtures can be composed of mineral, silicone or acrylic binders, but form a similar coating due to the presence of textured fillers.

The peculiarity of the “bark beetle” mixture is the presence of granules of 2 mm or more in size, which, when rubbing the composition, leave on the surface of the grooves, resembling the moves of the bark beetle. On sale there are mixes for brick and concrete, stone facades and for GVL. You can purchase a facade bark beetle plaster in the form of a dry or ready-mixed mixture, which is diluted with water if necessary. The durability of the coating will depend onwhat kind of base is chosen by the consumer. The maximum service life is shown by silicone mixtures, the minimum - by cement-based mixtures.

The basis of a variety of finishing plaster "lamb" is cement, so it is sold as a dry mix. The composition contains additives in the form of dolomite, quartz, marble and others.

This coating has difficulties in applying and requires hard work and practical experience.

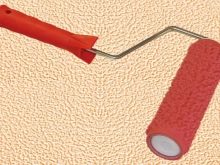

The covering of the facades in the form of a “coat” made of plaster is used for a long time, but has not lost its popularity so far. The effect of "fur" is obtained on the surface through the use of special rollers. The process of applying is not too complicated and quite capable of beginners. Today, consumers are offered more durable and aesthetically attractive mixtures than 10 years ago, made on the basis of cement with various additives, as well as on the basis of silicone or acrylic resins. "Fur coat" looks great in color. To do this, in a white mixture, you can add a different color or apply paint after drying the surface.

Mosaic plaster is a composition of a glassy look, the base is transparent resins, small stones (granite, marble, dolomite, etc.) act as a filler. Such decoration will decorate the basement of the building, slopes and balustrade.

Consumption

The amount of coverage that will be required to finish the facade depends on the following factors:

- the condition in which the wall is located;

- characteristics of the plaster mix.

With the help of facade plaster it is possible to level the walls, hide minor defects in the masonry and create decorative volume effects. All of these tasks require calculating the amount of plaster mix. It is impossible to determine “by eye” exactly how much the mixture will be needed. Initially, the calculation is carried out on the basis of the consumption of the coating required per 1 square meter. The curvature of the walls is measured using a building level, establishing beacons, calculating the average thickness of the facing layer. The more beacons will be installed, the more accurately it will be possible to calculate the arithmetic average value, and to determine what layer of thickness will be needed to align 1 square meter. m

On the packaging of ready-to-use plaster mixes always indicate the approximate consumption required for applying a 10 mm coating. Based on this value, the flow rate is calculated at the required middle layer of application. For example, if the average thickness of the plaster layer is 30 mm, then the figure indicated by the manufacturer should be multiplied by 3.

To determine the total consumption, the resulting value is required to be multiplied by the number of square meters of the surface to be plastered.

Different consumption of plaster mixes manufacturers may differ, therefore it is necessary to initially decide on the choice of a company that causes maximum trust and offers the most convenient price tag. For example, for acrylic facade plaster Ceresit CT 60, which belongs to the variety “pebble” or “fur coat”, the mixture consumption will be 2.6–2.8 kg / m² (for a variety with a grain of 1.5 mm) and 3, 4–4.0 kg / m² (for a mixture of 2.5 mm “grain”).

CT 72 Ceresit silicate plaster, which also belongs to the “fur coat” type, has the following flow rates: 2.1–2.5 kg / m² (“grain” 1.5 mm) and 3.8–4.0 kg / m² ("Grain" 2.5 mm).Ceresit CT 60 “fur coat” silicone plaster has a lower consumption: 2.1–2.5 kg / m² (when 1.5 mm grain is used) and 3.8–4.0 kg / m² (when particles with a size of 2.5 mm). Ceresit CT 35 bark beetle plaster has a consumption of 2.0 kg / m² (2.5 mm “grain”) and 3.0 kg / m² (3.5 mm “grain”).

Based on a comparison of the data, it can be concluded that the most consumable among the mixtures of Ceresit are acrylic and silicate coatings. Silicone facade plaster has an average value, and the mineral mixture is the most economical.

Instruments

For plastering of the facade, special plaster-painting tools are used. Many of them are universal, but there are also those that have a highly specialized purpose. The choice of the most convenient inventory depends on the preferences of the master plasterer and on the consistency of the mixture used.

The trowel, which is used to throw a solution on the wall, has many varieties that differ in the shape of the canvas, namely:

- the stucco trowel has a heart-shaped canvas; it is designed to knead the plaster mixes and apply them on a falcon;

- the trapezium-shaped trowel is needed directly in the plastering process;

- for grouting the outer corners, an angular trowel is used, which is called the forecut.

Among other plaster-painting tools should be the following:

- falcon, which is a square pad with a handle, can be made of plastic or stainless steel. It serves to transfer the plaster mixture and to distribute it on the wall surface;

- hopper (plastering bucket) allows you to throw the solution on the wall;

- putty knife, which can be of various sizes, and also helps to throw plaster on the wall and level it on the surface;

- graters, trowels and rules are made according to one standard and are used to distribute the plaster solution over the surface. The rules are long aluminum or wooden slats, sometimes with a built-in level to facilitate control of the deviation from the plane. The graters and trowels have a rectangular base, on which a convenient handle is attached. The surface of the float is usually covered with foam or sponge. These tools are used for finishing the alignment of plaster;

- roller with different surfaces is used to create a decorative effect, for example, "fur coat";

- for mixing the dry composition with water is used construction mixer;

- large plastered facades are polished with grinding machines;

- beacons and building level necessary to control the level of the resulting surface;

- corners used for mating surfaces;

- reinforcing mesh ensures the prevention of cracks.

For coating large surfaces there are pneumatic systems that greatly facilitate and accelerate the work of plasterer. For the manufacture of sprayed plaster mixture in large volumes used mixing plants. The cost of such a tool is quite high, so usually they are staffed by brigades representing major construction and repair companies.

Drawing

The application of facade plaster requires knowledge and practical experience, however, having studied the basic technological requirements, a beginner builder can also perform the plastering of a not too large facade.

The basic rules for finishing the facades with plaster are:

- it is worth remembering that all work should be carried out at above zero temperature, but not in too hot weather: from + 5 ° C to + 30 ° C. The moisture level should not exceed 70% for normal setting of the mortar. It is not recommended to apply plaster in rainy time, and the direct rays of the scorching sun should also be avoided;

- for work it is necessary to install scaffolding, to prepare the necessary tool, to purchase in full plaster mix;

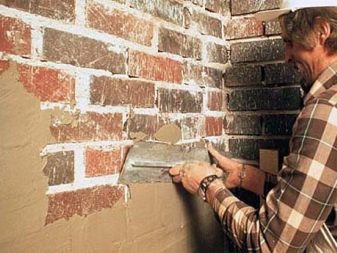

- Initially, it is necessary to prepare the surface of the wall: remove foreign objects that interfere with the work, for example, air conditioning, and also remove the old layer of plaster, if there is one;

- before applying the plaster composition, the wall must be cleaned of dust and treated with a primer;

- when the renovation of a private house “with history” is carried out and the surface of the walls needs to be strengthened, for example, when plastering old brickwork, the treatment is initially carried out with a special reinforcing primer;

- the surface of the wall is covered with construction mesh;

- installation of beacons;

- a layer is applied, leveling the base along the beacons;

- so that later there is no peeling of the plaster, in no case should we neglect the application of primer between the layers of plaster coating. Primer mortar fixes and polymerizes the plaster layer, making it more uniform, while it does not form on the surface of the film;

- after the primer dries, a decorative layer of plaster is applied;

- rubbing of the surface is carried out, if it is provided for when designing the facade;

- painting if necessary.

Tips and tricks

Plastering the facade will seem to novice builders not too complicated, if they consider the following practical tips:

- it is necessary to follow as accurately as possible the technology of mixing a dry mixture or diluting the finished mixture;

- during the work it is necessary to observe the maximum accuracy;

- it is important to prepare the entire tool in advance and purchase building materials in full;

- For the entire technological cycle it is necessary to use the same ingredients;

- the entire surface to be treated must be properly divided into capture zones;

- if the beginner plasterer has absolutely no experience, it is worth starting to master this profession from small areas,practice on the walls of the garage or other outbuildings;

- during the execution of the trial work, it is worth paying attention to whether the surface is not spotted and to ensure that the plaster lays flat as a result;

- if it is impossible to avoid stains and stains, you should choose a mixture that stains well when finishing;

- the application of silicone paint during the finishing finish will increase the strength of the coating;

- for beginners, the most convenient composition is an acrylic-based bark beetle plaster, as it allows the correction of errors and blemishes in the course of work;

- dry mixes should be used only if you have confidence in your own experience and skills, otherwise it is better to use ready-made formulations.

Manufacturers

Modern manufacturers produce a very wide range of facade plasters. The most popular are such brands as Bolars, Ceresit, Bravo. Decor, Weber-Vetonit, Knauf, "Found the Russia", "Volma" and "Plitonit".

Ceresit offers the Russian consumer a full range of plaster mixtures for facades, ranging from mineral to silicone.Among them there are elastic compositions, for example, a silicate-silicone mixture Ceresit CT 175 or a composition for use on cellular concrete Ceresit CT 24. Among the textures are dominated by “stone” mixtures with different sizes of “grain”, “bark beetle”; mosaic plasters are also offered. The cost of ready-made polymer blends is about 2 thousand rubles for 25 kg, the most expensive are mosaic compositions - 4.5 thousand rubles, mineral plasters have the lowest cost - from 700 to 1 thousand rubles.

“Bolars” with its “ridge” made the production of heat-insulating plasters, which included light granular fillers. Such mixtures have a multi-purpose use in modern construction, as they are suitable for both internal and external works. For example, EasyWall frost-resistant mineral-based plaster, designed for at least 50 cycles, is able to replace, according to the manufacturer, heaters such as polystyrene foam and a mineral plate.

The cost of a package weighing 11.5 kg is about 450 rubles. This company also offers decorative plaster: “stone” and “bark beetle”.25 kg of white "kameshkovoy" plaster "Bolars" cost about 550 rubles.

Bravo company. Decor also produces various plaster mixes for facades and plinths. Among them stands sprayed acrylic blend "Versaille", which is positioned as an anti-vandal coating. The manufacturer claims that this composition does not require careful surface preparation, it is flexible and covers minor irregularities and cracks. The cost of a container having a weight of 15 kg is 2.5 thousand rubles.

Knauf offers cement facade plaster Unterputz, which has a very reasonable price with all the well-known quality of the brand: the cost of 25 kg of the mixture is 225 rubles. Approximately in the same price range there are cement plaster compositions from Russian companies Plitonit and Volma, which have a price from 250 to 300 rubles for 25 kg.

For more information on the bark beetle plaster, see below.