Finishing putty for painting: selection criteria

The use of wallpaper in the process of finishing the room allows you to hide certain flaws and defects of the wall covering, but if painting is carried out, any flaws will be clearly visible. That is why, before carrying out such work, it is imperative to process the wall using finishing putty. The use of such a building mixture will allow you to create a smooth and smooth surface, on which paint is easily applied.

Functions and features

Finishing putty is a dry mix, which is used for the highest quality leveling walls. In addition, thanks to this solution, you can quickly hide small defects on the wall surface and increase the strength of the leveling layer.

A distinctive feature of the finishing putty is that it includes special components that provide ductility and ease of use of the material.

Among the main advantages and distinctive characteristics of the finishing putty are the following:

- Impressive adhesion properties, thanks to which the mortar adheres firmly to the wall surface.

- Putty is devoid of lumps and other flaws that are inherent in other mixtures.

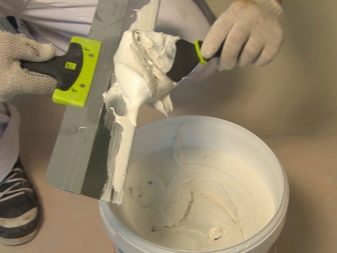

- Ease of use. Any person who did not carry out any finishing works earlier will be able to cope with drawing.

- Cracks do not appear on the surface after drying.

- The possibility of applying high-quality paint, which will fall evenly.

It is extremely easy to distinguish the finishing putty from the usual one: the first option is distinguished by small fractions, and the second by large ones.

The application of the usual construction mixture is the initial stage of finishing work to improve the condition of the wall covering, but the use of the finishing is the final stage of finishing, the purpose of which is to increase the strength characteristics of the wall.

Classification

In order to choose the right mortar, you should carefully study its varieties. On the current market there are the following options for finishing putty, depending on the componentswhich are part of:

- Cementwhich boasts impressive water resistance. Due to this, such putty can be used without problems in rooms with high humidity levels. In addition, this type of mixture is great for carrying out the exterior. A distinctive feature of this composition is incredible strength. It can only be damaged if hit by a heavy object.

- Gypsum. Because of its sensitivity to water, it cannot be used in damp areas. The main advantage is the fact that the gypsum does not shrink after drying, and no cracks or chips appear on its surface. In addition, gypsum putty boasts an affordable price. Among the qualitative features of the gypsum mortar can be distinguished resistance to fire, quick drying and unique antiseptic characteristics.

- Polymer Appeared relatively recently and is not famous for its resistance to water. The only advantage of this solution is its elasticity, which has a positive effect on the thickness of the applied layer.In addition, the finished solution is not necessary to use immediately - it can be stored for several days. Among the advantages of the polymer mixture can also be noted resistance to rapid temperature changes, which are considered the most serious enemies of putty and often become the cause of their damage.

When choosing a specific kind of putty should be repelled from the material of the walls. If it is concrete or brick partitions, then it is best to give preference to cement varieties, but for the finishing of drywall gypsum plaster is the ideal solution.

As for materials with polymeric composition, such putties are considered universal.

Regardless of the putty used, you should understand before choosing that a quality product must meet the following criteria:

- Adhere well to the wall and extend the life of the wall covering.

- Easy to apply.

- Hide small wall defects.

- Have a white tint, which is extremely important for further painting.

- Do not crack during the drying process.

Tips for choosing:

- A significant role in the process of selecting the finishing putty plays a place of work.If you plan to decorate the facade of the house, it is best to choose an option with good thermal insulation properties. The use of such a building mixture can effectively solve the problem with cracks and prevent excessive heat consumption.

- For finishing the walls in the bathrooms are excellent option finishing putty, which are made on the basis of cement. The presence of this component makes them an ideal solution for rooms characterized by high humidity.

- Walls and ceilings in residential areas are best treated with a polymer mixture, which is characterized by thin layer and will result in an attractive appearance of the wall surface.

Top Marks

On the modern construction market there is a huge number of manufacturers of finishing putties, so it will be difficult for an inexperienced person to make the right choice. Among the most popular brands that have managed to establish themselves on the positive side, the following can be highlighted:

- Knauf HP Finish - gypsum plaster, which boasts an affordable price and helps to make smooth walls in any room.The unique properties of this material allow it to be used for finishing ceilings, concrete or plasterboard walls. According to the manufacturer, the mixture dries completely in 24 hours.

- Vetonit LR +. One of the most popular putty on the market. Great for use before painting. The presence of polymer components allows the use of "Vetonit LR +" only in rooms that are characterized by a normal level of humidity.

- "Eunice Premium". Another high-grade polymer mixture, which will be the ideal solution for walls before painting. With this mortar, you can get a perfectly flat plane.

- Sheetrock - a unique superfinishing ready-mix, which consists of vinyl binder and dolomite, as well as special additives that enhance the properties of putty.

In the process of choosing the most optimal building material for finishing walls before painting, close attention should also be paid to the compatibility of the base and finishing putty. It is best to give preference to products from the same manufacturer. The fact is that, with poor compatibility, one type can harm the second product, which will adversely affect the properties of materials and may cause their flaking or complete loss.

Completely determine the choice of finishing will help the correct calculation of the amount of putty that is needed for application. This affects not only the surface area of the wall, but also the thickness of the applied layer.

Following simple tips, you can choose the most optimal and suitable type of finishing putty that will fully meet all technical requirements and help you create an attractive and stylish interior. In the process of selecting the finishing putty you need to be extremely careful, because It is this material that determines the strength of the wall and its aesthetic appearance.

On how to polish the walls after putty for painting with your own hands, see below.