Subtleties of the choice of finishing putty

Very often, repair is associated with large loads and large expenses, especially when it is necessary to select and purchase all the necessary materials. It is very important to carefully familiarize yourself with all the stages of work, so that the result will be pleasing to the eye as long as possible and worth the effort.

Let's look at the main points of working with finishing putty - an intermediate link between the basic alignment of the walls and the final decoration using wallpaper or staining.

In the recent past, the concept of finishing putty did not exist. After removing the old wallpaper or plaster on the raw wall just put a new layer of plaster or glued fresh wallpaper. If there were cracks or irregularities in the walls, they were simply smeared with a solution of cement, there was not even a speech about the finishing putty.

Over time, the situation has changed,and today on the market offered many options for the final putty, which serves to give the surface an ideal evenness and uniformity. The features of this type of material will be discussed below.

Special features

To date, the final putty has become commonplace. Often ennoble the wall in several stages, applying different coatings one after the other. Each new layer differs from the previous one, as a rule, in the composition and quality of the coating. The final should have good adhesion, that is, improved adhesion to the finish.

The topcoat is used for the following purposes:

- Final surface alignment at the end of all finishing works. Also used for filling small cracks or scratches, smoothing roughness.

- Used to extend the service life of the repair, as it protects the walls from damage.

- Protects the base putty layer from destruction and the adverse effects of external factors, fixes the result of applying the base.

- It is the final touch in preparing the walls for decoration. - aligns the coating, making it smooth, aesthetically complete.

Finishing putty used at the very endto give the coating a finished look. This type of material is used for interior work and in most cases it has a boiling white color and a smooth texture, unlike the base putty. This is of great importance when sticking light, thin wallpaper or wallpaper with a small print.

Particular attention should be paid to the walls if you wish to issue them with silk-screen printing or fabric wallpaper - the final appearance of the wall should be impeccable. The same requirements are imposed on the surface when painting, no matter what the composition of the dye. Finishing plaster differs in the minimum size of granules, color and gloss elements.

When choosing a finishing putty, pay special attention to the properties that this finishing mixture should have:

- smoothness of the composition, providing good application to the starting surface - no lumps and excessive thickness of the mixture, easy application, it does not stretch the threads for the tool and does not leave streaks;

- does not trickle down as applied;

- covers cosmetic imperfections with a coating thickness of 3 mm, with a thicker coating completely hides the defects of the main base;

- does not form cracks as it dries, it does not give a porous coating;

- on the fact of application gives an even white color without additional pigmentation;

- doesn't shift in the bottom of the wall.

Kinds

Currently on the market there are many options for finishing putty. To choose the appropriate option for a particular room, you need to familiarize yourself with the main types of this type of material.

Finishing putty is divided into types in accordance with the constituent components:

- cement;

- gypsum;

- polymer;

- acrylic;

- oil-glue.

Cement putty has a relatively low price, easy to use. Perfectly is suitable for the rooms having high level of humidity (for example, a bathroom) as it is not hygroscopic. For the same reason, it is often used for outdoor work. The cement composition is easy to use, as a long time after application allows you to quickly eliminate possible shortcomings.

Of the minuses, I would like to note the fact that the cement mixture shrinks after hardening and, as a result, cracks may form on the surface.

It is necessary to make polishing of the top layer before full drying, after it it is almost impossible to make.

Gypsum mix characterized by uniform application and leaves a smooth matte finish. Extremely It is not recommended to use this type of putty in rooms with high humidity. - gypsum easily absorbs water. Best of all, this coating is suitable for bedrooms, living rooms and children's rooms, especially if it is finally planned to apply a decorative coating on the plaster in the form of wallpaper, for example. Unlike cement, does not shrink, it can be applied with a thick layer.

Gypsum coating is environmentally friendly and does not cause allergies. This coating dries very quickly, so to work with it you need to have certain skills - the mixture diluted in a bucket should be used for half an hour, then it starts to harden and becomes unsuitable for further use. Its price is also low.

Polymer putty It is much more expensive, but it has a number of invaluable qualities, for example, storage time - the ready solution is stored for a long time. Sold in a usable form, but to get started it only needs to be mixed thoroughly. Apply to the surface in a thin layer.It has a high degree of adhesion.Due to the variety of color palette perfect for decorative wall decoration. Does not shrink and does not crack, plastic, non-hygroscopic, has a long service life.

The smaller the diameter of the polymer fractions, the smoother and smoother the final coating will look. Often, after surface treatment with a polymer composition, surface painting is no longer required and it is often used as a super-finish.

Acrylic putty it is used both for front works, and for internal finishing. It has high plasticity and is suitable for filling cracks in walls. At the end, it gives a durable layer that protects the surface from external aggressive influence. It is moisture-proof, perfectly fits on different types of surfaces, including concrete and wood.

This type of putty can be purchased in the form of dry powder, and in the form of ready-mixed. Acrylic does not shrink and does not crack.

Oil-adhesive, as the name suggests, contains drying oil and glue. Resistant to abrasion and possible mechanical damage, moisture resistant.

Another important component of the mixture is lime - notice that the size of the fractions fit the baseotherwise the mixture will be of poor quality.

Polymer putty is ideal for do-it-yourself repairs due to its ease of use.

It is easy to apply and does not require additional skills in carrying putty work.

Manufacturers

Currently, the buyer offers multiple options for putties, the main thing is to choose the appropriate one for specific purposes.

Before buying materials, be sure to read the reviews and see the ratings of manufacturers:

- Presently Vetonit company widely represented on the market. She has a variety of options for interior decoration, but this type of product is too hygroscopic and is not suitable for working in the bathroom and toilet rooms. Also not recommended to use this type of putty for flooring. Suitable for subsequent staining.

- Firm "Hercules" exists on the market for over 20 years and continues to evolve and improve the production of construction chemicals. Today, the company offers a wide range of dry mixes - they can be simply diluted withwater according to the instructions. Mixtures have a variety of characteristics - there is a waterproof, non-shrink and others. Every buyer will find among them what he needs.

- KP putty suitable for leveling both cement and gypsum surfaces, can be applied both manually and with the help of the apparatus. Possesses high resistance to soil and wallpaper glue.

- Materials of the “Osnovit” company possess a wide range of properties: frost-resistant, reinforced, weather-resistant, crack-resistant, non-shrink, resistant to abrasion. Suitable for finishing as for facades and plinths of buildings, as well as indoors.

- Plaster "Euro-L" from the company "Polimerstroy" also well established in the market. The company continues to experiment with formulations using unique formulations for the production that meet the latest requirements of the construction industry.

- Putty "Bolars" consists of gypsum and polymer additives. It is excellent for covering up cracks, eliminating potholes and crevices, it is applied to any surface - be it drywall or brick; it is excellent for forming decorative elements because of its plasticity.

- Materials from Unis differ in low cost, are suitable for thick-layer alignment. The paint perfectly lays on such a surface.

- Semin long ago came to Russia from France, currently has its production in the Tula region. The products of this company has the highest score in terms of environmental friendliness.

As a rule, the choice of putty is carried out in accordance with the following technical characteristics of the mixture:

- viscosity;

- consumption;

- size of fractions;

- strength;

- adhesion;

- acidity;

- susceptibility to temperature extremes.

Tips for choosing

Very often, people who have started repairs, wonder whether they need a final putty before decorative surface finishing.

Experts insist on the mandatory conduct of this type of work for the following reasons:

- irregularities and cracks on the surface of the plaster lead to peeling of the wallpaper, the appearance of unwanted voids and bubbles on the canvases;

- if the walls are made of drywall, screws that are susceptible to corrosion over time can give rust that will tread through the wallpaper and ruin the exterior aesthetic appearance;

- base coat uneven in color and texture can spoil the appearance of the final wall decoration;

- the coarsest on the texture of the wallpaper will not hide the cosmetic defects of the walls;

- joints between sheets of drywall need to cover up, otherwise the type of interior will be damaged.

First of all, decide for what type of surface to choose the final putty - for the floor, walls or ceiling.

If there is a need to process the ceiling, pay attention to the plaster mix. It is white in color, forms a thin coating, has a matte finish, evenly applied, quickly hardens. The average time for full setting varies from 14 to 24 hours, after which the surface is ready for painting or another type of final finish.

According to the form of release, the putty may be ready for use or may be in the form of a dry mixture. In the first case, the mixture is ready to work, in the second, it must be diluted with water in accordance with the instructions and get to work while it is wet, as the mixture hardens quickly.

Bath and toilet have high humidity, there are temperature fluctuations in the kitchen, so for this type of room it is better not to use plaster and polymers based plaster, their adhesion properties fall when colliding with an aggressive environment. therefore for this type of premises it is better to give preference to cement-based putty, because it does not let in moisture.

Consumption

An important aspect is also the consumption of material during the work. Therefore, when choosing a finishing putty, pay special attention to the layer thickness - to do the job better, treating the entire surface with one compound. Otherwise, the possible deviation of colors, which may adversely affect the appearance during the finishing works.

An excessively thick layer may peel off over time, an excessively thin one will not fulfill its function. on the correction of the texture of the base putty.

Carefully read the instructions for use and based on the information received, calculate the consumption of the necessary material. Take into account the entire working area, as any of the composition prepared after portions may have a difference in the shade of white.

Of particular importance is the final decoration of the coating, for example:

- vinyl wallpaper fit single-layer finishing putty surface;

- in case of further painting the surface with acrylic paint, two layers of putty are needed;

- when using polymer as decoration - two or three layers of putty;

- the lighter the tone of the final decorative coating, the thicker the layer of finishing putty should be.

The topcoat is usually applied from the center to the edge, and if necessary, first across the seams, then along them.

For complete drying, the finishing coating needs at least 12 hours, after which the surface is ground with fine-grained sandpaper to obtain a smooth surface. note that only gypsum or polymer coating can be ground, cement on the fact of drying is impossible to grind.

When sanding walls for the subsequent pasting with wallpaper, you can not make special efforts, since all the shortcomings will still be hidden, and when painting, on the contrary, close attention should be paid to sanding.

The average consumption of material is 0.5-1 kg per 1 m2, but, in any case, it is necessary to calculate the thickness of the layer during application and take into account the consistency of the finished composition.

Application technique

As a rule, surfaces are prepared for painting in three stages: primer, application of the solution and, in fact, the final puttying.

Before filling the base surface, it must be primed. for improved adhesion between layers and moisture resistance. In most cases, a primer based on acrylic is used as a primer. Sometimes this stage is skipped, but experts do not recommend neglecting it.so that the final result of the final finish serves as long as possible and pleases the eye.

Before priming, it is necessary to prepare the surface with a basic putty, as well as remove all possible dirt and grease stains; otherwise, after the mixture dries, stains may appear on the final coating, which can no longer be eliminated.

Finishing putty is available in finished form or as a dry mixture, and the cost of the latter is lower by about 20%. Self-preparation does not conceal the pitfalls: to dilute the dry mixture, you must first prepare a suitable size container. For these purposes, as a rule, use plastic containers. Metal is not recommended - in the process of mixing with a construction mixer, metal particles can get into the prepared mixture and give rust.

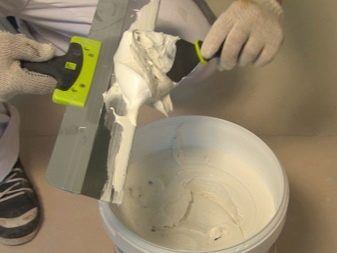

The mixture is diluted with cold tap water and mixed using a construction mixer. or a construction drill until a homogeneous mass without lumps.

It is further recommended to leave the mixture for a few minutes and re-mix. The finished mixture has the consistency of sour cream and is completely ready to get started.. Also be guided by the thickness of the desired coating - the thicker the layer, the thicker the mixture should be.

Before the final putty with a roller or rag can moisten the wall with water. This will improve adhesion and help make the layer thinner.

For the work will require three different spatulas. A narrow spatula will be required for taking the mixture from the tank and applying it on the wall — it needs to be applied crosswise, and wide for spreading it over the treated surface. note that putty should not drain from the spatula, on the contrary, should be kept on it. A wide spatula blade should be wiped with a damp sponge before spreading each new batch of mortar over the surface. This is necessary for a uniform coating without stripes, grooves and scratches.

For work in hard-to-reach areas, such as joints of the ceiling and walls, as well as for processing corners, an angular spatula is used.

Useful recommendations

It does not matter whether the putty material from a well-known manufacturer or not, the most important thing is that it meets the requirements of the premises. Cement mixes are better suited for exterior decoration, for work inside buildings, they are less suitable, since over time they can produce cracks, and they are also inferior in smoothness.

At low humidity in the room is better to use materials based on polymeric materials.. If the base surface coating has roughness and unevenness, it makes sense to give preference to gypsum putty - it allows the application with a thicker layer, which will help to hide the flaws of the main surface. If the walls have a smooth texture, you can use a polymer putty. It is applied in a thin layer, which compensates for its high cost relative to the plaster material.

It is highly desirable to take into account the compatibility of different types of material and use for the base and finish a mixture of the same manufacturer. Before finally making a choice, it makes sense to calculate the consumption of material based on knowledge of the work area and the thickness of the putty layer.

Do not forget that the preparation of the surface for painting requires compliance with certain conditions:

- apply a new layer of putty only after drying the previous one;

- emery paper is used for leveling the surface - coarser for basic putty and finer for finishing;

- for maximum quality, you can use the skin with an index of 240, a handskin will also significantly facilitate this stage of work;

- after sanding the final coating, it is necessary to remove dust from the surface;

- priming the last layer of putty is necessary for a more even application of paint on the surface;

- The easiest way to check the quality of the work done is to use a powerful lamp or a flashlight - moving the lamp across the surface at different angles can notice flaws and irregularities.

If there are cracks in the walls, it is best to pre-cover them with gypsum putty, which has the following characteristics:

- very plastic;

- freezes quickly;

- For better leveling of the surface, you can scratch the cracks before working.

After finishing the putty, the walls must be primed again.This procedure will help make the glue layer more durable, as well as protect the surface from the possible appearance of mold and mildew. Wall-paper is better placed on the primed surface.

Review and comparison of finishing putty, see the following video.