Features siding with imitation bricks

Every day more and more new materials appear on the construction market, the manufacturers of which speak of their uniqueness and the best performance characteristics. How true is this and can brick siding replace traditional brickwork?

Special features

The brick house of the majority at the subconscious level is associated with reliability, monumentality. Choosing one or another type of material, it is possible to create objects that are different in style. However, such buildings always look respectable and demonstrate good taste and status of the owner.

Among the disadvantages of brick structures - a large weight of the walls. This requires the preparation of a solid foundation, which requires considerable financial costs, an increase in the installation time and an increase in the labor intensity of the process. Finally, not every type of soil can build a heavy monolithic foundation.You can get a functional, durable and attractive building only by observing the technology of laying bricks. Not every ordinary house owner has enough skills and knowledge for this, therefore it is more expedient to involve professional masons in the work. This again turns into an increase in estimates.

Finally, it is worth noting the high cost of bricks, as well as a fairly large consumption of concrete solution, which also complicates the installation process, increases its cost.

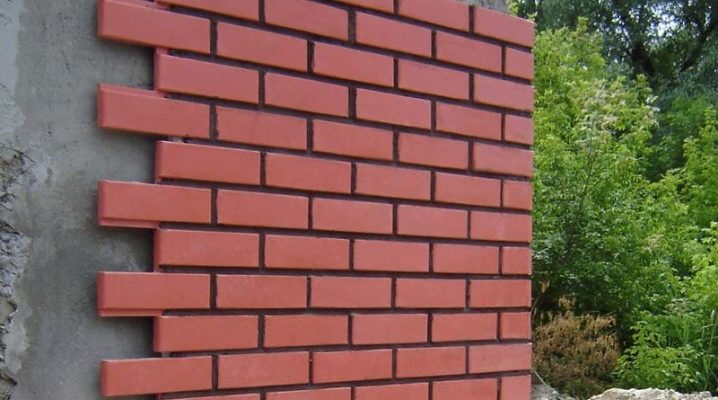

Brick siding provides a similar effect to a brick house. with a significant reduction in material costs and simplified construction work. Siding refers to rectangular panels that are used for exterior cladding. For fastening of these panels use fasteners - self-tapping screws. The siding profiles themselves are mounted on a wooden or metal crate pre-mounted on the exterior walls of the house.

Siding can be made of various materials, and also to imitate various surfaces - finishing under a brick, a tree, a stone. Thanks to modern technological advances, it is possible to achieve maximum imitation - not only at the visual level, but also at the level of tactile sensations,arising from touching the material. Not everyone can detect imitation even at close range.

The advantage of siding panels is their low weight. Depending on the material, there is 5-25 kg of weight per 1 m2. This allows you to sheathe even light frame or wooden buildings, as well as slightly heavier foam-and gas-concrete houses, built on lightweight foundations. The latter, by the way, does not need additional strengthening.

The brick itself is, as you know, a rather cold material, so in such a house it is necessary to think about powerful insulation. However, many homeowners do not want to close the attractive walls of a brick house, so you have to look for "devious" ways to improve heat efficiency. Siding is mounted on the technology of ventilated installation, so insulation is laid between the panels and the walls of the house. Varying this air gap, you can choose the thickness of insulation necessary for thermal insulation. It should be noted that the technology of the ventilated facade itself contributes to an increase in heat in the room.

Finally, siding has a much lower cost.Reducing costs due to more simple transportation of material, the ability to do the work with their own hands, even without being a professional builder.

Kinds

Depending on the type of material used, the following siding types are distinguished:

- Vinyl. It is made by pouring molten polyvinyl chloride into special shapes, the surface of which has a pattern for a brick. As a result, lightweight panels are obtained, imitating brickwork as accurately as possible. The advantages of the material include its low weight (easy to transport, store, you can install even alone), price affordability. The material is resistant to UV rays, is not afraid of precipitation, high temperatures, as well as their abrupt change, bio-racks (mold does not appear on the surface, fungus, it does not attract rodents).

It should be noted that the facing vinyl siding is completely harmless from an environmental point of view and is suitable for finishing houses. The disadvantage is the low fire hazard of the material, depending on the characteristics of the type, it belongs to the fire resistance class G1-G4 (low-combustible-highly combustible).

Despite the relatively high cost, with a strong mechanical action, such as impact, the surface of the material can go cracks and even break. In this regard, some homeowners refuse to use vinyl panels in the basement of the building, on the ground floor level.

- Metal. Metal siding is a metal-based panel with a reliable anti-corrosion coating. This allows you to level one of the main drawbacks of the metal - its tendency to corrosion and the resulting reduction in the quality and durability of the material. The production of profiles can be carried out by cold rolling or by stamping, but galvanizing of the surface is obligatory in any case. Such "iron" siding has a slightly greater weight than plastic, but it is still considered as light material and does not require strengthening the foundation. It is fire resistant, environmentally friendly, weatherproof and durable. Where the vinyl siding splits from impact, there may be no trace of impact on the metal surface or there will be an inconspicuous dent.

The cost of metal panels is higher than the price of vinyl, however, they have a longer service life, increased strength characteristics.

- Fiber cement. At the heart of fiber cement siding - a mixture of pulp, cement and special additives that increase the performance characteristics of cement. Due to this composition and production features, they are durable as concrete, but much lighter and warmer material imitating a brick surface. Fiber cement siding is resistant to the negative effects of environmental factors, reliable and durable to mechanical stress. They also produce insulated siding, which greatly simplifies and speeds up installation. A large weight causes an increase in the labor intensity of installation - several people are required for work. The cost of the material is also higher than the considered types of siding, but at the same time it is more durable and has a longer service period. Fibrocement-based panels are more often used to finish a base more vulnerable to damage.

Fiber cement siding is much heavier than vinyl and metal counterpart, so it is not suitable for every type of house. As a rule, it can not be mounted on the "skeleton" and old houses.

- Bituminous. Appeared relatively recently, is a soft material that is stuffed on a continuous crate. According to its texture, it is somewhat similar to soft roof tiles. The main advantage is convenience in work, especially on complex (semicircular, for example) facades. There is no defined GOST that regulates the size of siding. Each manufacturer produces products in its own overall versions, but most of them are the same or very close. On average, the size of the panels is 100x50 cm, there are changes upwards or downwards. Standard decorative siding height - 3.4 m.

Depending on the place of installation and destination, wall and basement panels are distinguished. The latter are intended for installation in the lower part of the building between the foundation and the facade - in the area of the basement. They are more thick and durable, have the shape of rectangles (usually the height of the panel is equal to the height of the basement), convenient for work.

Design

This modern brick has many modifications, differing in color, texture, dimensions. However, high-quality imitation in its diversity is not inferior to the original.If we talk about the color performance, then the most popular brick shades of panels are typical - burnt bricks, red, yellow, sand, white. Exclusive front siding can imitate agate, malachite, granite shingles.

Among the most common textures siding "bricks" emit a smooth and textured products. The first is optimal for a log house, as well as a background for textured surfaces. The latter have furrows on the surface and an original pattern. A kind of textured can be considered as profiles that mimic a shotcrete brick. Mineral crumb is applied on its front side, due to which an original texture is obtained, iridescent in the sun.

Attractive and elegant look at home, sheathed with siding with imitation clinker covered with glaze brick. To create a particular style, you can use panels that resemble the surface of the Antique brick. This is an artificially aged product.

Installation

Facing the facade begins with the calculation of the required amount of material and the preparation of external walls.For the calculation of the material there are many formulas, as well as online calculators that will make the necessary calculation.

In general, find out how many panels you need, by calculating the area of the facade (multiply the length of the wall by the width, we add the areas of all the walls). Knowing the width and height of siding, you can calculate how many pieces of panels will be required. It should be noted that window and door openings do not get off (subtracting their area from the total value), in some places the siding will have to be cut (we add “pieces” to the total number of panels). Siding should always be purchased with a small margin: for objects of simple configuration it makes up 7-10% of the total amount of material, for houses of complex shapes it is 15%.

Preparation of the facade includes the removal of the old cover (if possible), the removal of elements of communication. Large cracks and damage are eliminated, crumbling areas - reinforced. It is not necessary to carefully align small height differences, and also to eliminate minor flaws, they will disappear under the hinged system. This, by the way, is another advantage of siding.

On the prepared surface in accordance with the drawing, the layout of the future subsystem is made. Upon completion of this stage of work, you should once again check the accuracy of the contour lines and verticals, after which you can proceed to the installation of the batten.

The battens can be represented by metal profiles or wooden lags. Bearing capacity of the first higher, they are more durable. The wooden subsystem is suitable only for wooden walls and can be mounted on small one-story houses. Metal profiles must have a corrosion-resistant coating, wooden logs must be impregnated with antiseptics and flame retardants. Fastening is made on brackets.

The important point is that the calculation of the facade area should be carried out taking into account the batten, since it increases the width of the walls by 4-10 cm in each direction.

Siding is attached to the prepared crate with self-tapping screws. The panels have a lock mount, so the installation resembles the assembly of the designer. It should start from any angle, gradually moving along the walls. For the design of corners, openings and other complex elements of the house, you can use additional elements in the form of ready-made corners, platbands, etc.

In the conditions of the harsh domestic climate, a layer of insulation is usually placed under the siding panels. In this case, after installing the batten, insulation is laid between its profiles. Its thickness is calculated on the basis of thermal conductivity of the material of the walls, climatic conditions.

The width of the insulation should match the pitch grating. At the same time, great attention should be paid to the junction of the heat-insulating material and the batten, since when maintaining the gap in this place cold bridges will form.

Basalt wool or polystyrene foam is used as insulation (it is preferable to choose its extruded version). A layer of windproof membrane is superimposed on top of the insulation (it is also vapor-permeable and, at the same time, moisture-resistant). It is important to glue all the joints of the membrane film with scotch tape.

The layers of insulation and windproof film are interconnected by a single dowel, which fixes them to the wall. Umbrella type fasteners are used. 3-4 dowels are enough for one sheet of insulation, one of which is necessarily located in the center of the sheet.

After that, the siding is mounted as described above.Between it and the surface of the insulation, an air space 3-5 cm wide is always maintained. When installing vinyl siding, it should be taken into account that the material shrinks and expands when the temperature changes, so its installation is carried out with small gaps to avoid possible deformation of the material.

Despite the ease of installation of panels, it is better to work with assistants. Installing a 3-meter siding alone is not easy.

Manufacturers

Among the manufacturers of siding panels for bricks, the trust of customers in many countries of the world has won Foundry (USA) and Docke. The material we are interested in is represented by vinyl panels of not only the highest quality, but also the most realistic. American products have additional coatings, so that their class of fire safety - G1 (do not spread the flame, do not sustain combustion).

A distinctive feature of these materials are also the dimensions that are 150x25 cm (the standard size of plastic panels is 100x50 cm), which makes them more resistant to gusts of strong and even hurricane winds.

If we talk about the basement siding under the brick, then the world leader is considered to be the American Nailite company. As is known, the basement is experiencing increased mechanical loads and negative environmental effects, therefore it must be distinguished by its strength, moisture resistance, and resistance to environmental influences. In all these parameters, as well as with a realistic appearance, the products of this brand are significantly superior to the domestic counterparts on the market.

Among Russian producers deserves attention trademark "Alta profile", the main activity of which is the production of decorative panels for brick and stone. In this, the company has achieved great success - the material in its quality meets European requirements, but at the same time it is adapted for use in domestic conditions.

Another reputable brand that receives mostly positive customer reviews is Domestic company "Dolomite". From the name it is clear that the production is made up of panels imitating stone surfaces (dolomite is a kind of stone). However, in the collection you can find fiber cement panels under the brick. Their uniqueness is the 3-layer outer coating,so that the material retains aesthetic appeal for decades.

The optimal combination of price and quality also demonstrates Belarusian manufacturer "Yu-Plast". The disadvantage is a small range of materials under the brick.

Tips and tricks

Before purchasing panels, you should ask the seller for certificates of conformity of the material, the only way you can protect yourself from purchasing fake or nameless low-grade goods.

The facade trimmed with a siding is inclined to self-cleaning, however at strong pollution it can be washed. It is more convenient to use for this purpose a garden hose, choosing the optimal power of water pressure. The material does not need any special care.

Beautiful examples

Choosing the design of the future facade, you should take care that it is harmoniously combined with the exterior and adjacent buildings. To avoid monotony and make the facade more textured, the combination of brighter and darker “bricks” allows stylish.

Usually a dark shade is used in the basement of the house or at the corners and decorative elements of the facade.

"Brickwork" is well combined with a solid surface, as well as plastered walls.

A combination of stone and brick is considered to be a win-win. It should be remembered that the stone focuses on itself, so the “companion” to it should be selected panels with a smooth texture of a neutral shade.

The combination of bricks and wood looks good, although some designers say that such a union is a moveton. Resort to this reception or not - every homeowner decides for himself.

Finally, at home, sheathed with colored plastic siding, you can also diversify, adding brick "masonry."

You will see an overview of brick siding in the next video.