Siding features with imitation stone

The stone base is reliable and gives the house a respectable look. But stone is an expensive material, and working with it requires professional skills. A good alternative to stone will be finishing the base of the house with a basement siding under stone.

Special features

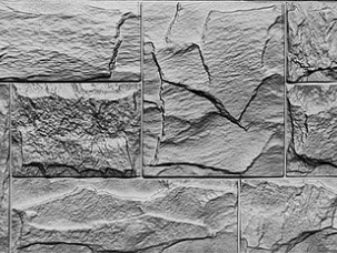

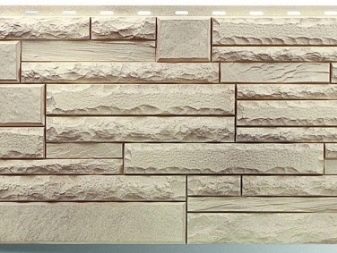

This material is produced in the form of an average width of shields, the surface of which repeats stone or brick masonry. There are many options: granite slabs, canyon, rubble and rocky stone - only some of them. The material is in demand, so manufacturers are constantly updating and expanding the range.

Details of the basement siding are thicker and stronger than the facade, better connected to each other. On the sides, they are cut along the boundary of the masonry fragments, which makes the boundaries between the shields almost imperceptible.By the way, basement siding is suitable for finishing the facade, and for the interior of the house.

The advantages of this material are much greater than the disadvantages.

The service life of the panels - at least 30 years - is comparable to the lifetime of the house. They do not darken and are not stratified by time. Siding does not deteriorate due to the action of natural factors: sudden changes in temperature, frost, rain, ultraviolet radiation. Withstands wind gusts up to 200 m / s. Panels fit well together. There is no need to use H-strips, which are necessary for the longitudinal connection of the facade panels.

It does not require special care, it is enough to wash dust off the surface from time to time. Creates additional thermal insulation. Imitations of various masonry are produced, so it is easy to choose an option that matches the color and design.

There are also "weaknesses" in ground siding.

The basement panels are thicker than the facade, which increases the load on the walls. The strength of the plating is inferior to the stone: siding can crack due to a strong impact, and to replace one or several parts, it is necessary to disassemble the entire surface.In case of fire, it does not catch fire, but begins to melt under the action of high temperatures.

Kinds

Depending on the raw materials siding panels can be divided into several groups:

- acrylic;

- vinyl;

- fiber cement;

- metal.

Their characteristics are noticeably different, so it’s worth discussing more about each variety. Vinyl panels are cheaper than others and cost from 200 rubles per sheet. However, this is not their only advantage. Low weight does not create an additional load on the construction of the house, and with the installation you can handle it alone. Unlike metal, vinyl siding is not susceptible to corrosion and better imitates the stone surface, since the outer part of the panels is embossed.

However, parts made of vinyl do not withstand severe mechanical damage. During a fire, they begin to melt, and with a large temperature difference expand. Improper installation may result in deformation of the plastic panels.

Acrylic siding is produced using a different technology, which makes it stronger than vinyl and more resistant to overheating. Such panels can withstand temperatures up to 380 degrees and do not respond to its fluctuations.But the price of this material is higher.

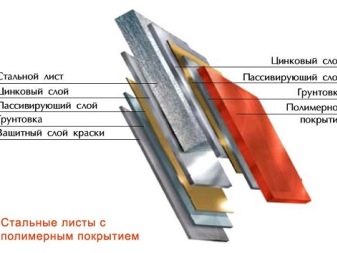

Metal panels are noticeably inferior to the polymer in beauty: a flat sheet of metal does not convey the relief of the stone. At the same time they are stronger, not afraid of fire and sudden fluctuations in temperature. The raw materials for them are galvanized steel, zinc and aluminum. The surface of the metal is coated with a polymer layer that protects it from destruction and corrosion. Another disadvantage of metal panels is problems with fitting. Most of these panels are difficult to cut. Basically, metal siding under stone is used for exterior decoration of socles and small technical buildings.

A sheet of material costs at least 400 rubles. Repeat the surface of the stone better polymer siding can only finish fibrosiding. It is made from cement, and strengthened with cellulose fibers and fiberglass. Outside the panel is covered with a polymer film that protects them from moisture and the action of sunlight. This type of siding - impact resistant, does not deform when the temperature drops, does not burn or melt.

At the same time, fibrosiding cannot be advised as the best finishing option. The thickness of its panels is 8-35 mm, and the weight is 12-15 kg, which is much heavier than polymer and metal counterparts. For cladding work will need at least two people.In addition, the price of 1 square. m fibrosiding comparable to the price of 1 square. m lining of natural wood.

The final choice will depend on many factors: the purpose of the building and the state in which it is located, the characteristics of the climate and installation. Another important criterion is the design of the panels: how much does it correspond to the style of construction and what impression does it create.

Design

The greatest demand is for vinyl imitation stone.

Panels can be divided into three groups:

- Painted in mass - uniform in color panels with a wide palette of colors.

- With highlighted seams - different from previous seams in a contrasting color.

- Exclusive - painted inhomogeneously, and the color repeats the colors of one of the types of natural stone. Due to the relief surface of the panels, it seems that the wall is made of natural material. The seams are the same color as the masonry mortar.

The design of a metal siding under a stone is less various. From the point of view of aesthetics interesting panels with a coating of plastisol: they are well convey the texture of the original.

It is worth saying more about the most popular imitations of stone.

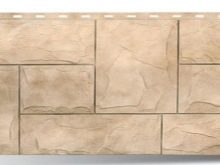

- Granite - material suitable not only for finishing the basement. With it, you can create stylish facades and partially use in the interior. The palette of this siding includes colors from light gray and brown to black. Dolomite is another type of basement siding, which can be used to sheathe the entire surface of the wall. The panels of light sand and lime colors will make the building elegant and light. White stone creates the impression of nobility and sophistication. In dry, sunny places, the finish looks most appropriate.

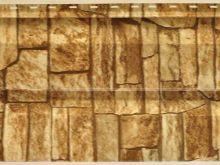

- Booth - imitation of large round cobblestones. The color scheme of the details repeats the color of natural samples - different shades of gray with a small amount of brown. Great for facing basement. If they cover the walls of the building, it will look like an impregnable fortress.

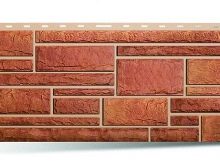

- Rocky stone imitate vinyl and fiber cement panels of different shades. Due to the rough surface of the panel under the wild stone are almost indistinguishable from the present laying.

In addition, in shops you can see siding, repeating smooth or aged brick, marble, fragments of old masonry.

Dimensions

The height and width of parts from different manufacturers is slightly different. In some cases, they depend on the size of the elements of masonry. For example, let's compare the collections “Stone” and “Rocky Profile”, which are produced by “Alpha Profile”. The panels of the first have a size of 1135x474 mm, a thickness of 22 mm, and the second - 1168x448, a thickness of 23 mm.

Docke is a well-known manufacturer in our market that offers the Stein collection. Dimensions of parts - 1126x426 mm. And another German company - Wandstein, produces panels of 795x595 mm in size, which simplifies installation.

Tips and tricks

If you plan to sheathe a large surface area with siding, it is better to choose vinyl panels. The overall load from heavier materials panels may be critical. And low walls made of concrete or brick can withstand any kind of decoration, including fiber cement panels. Calculate the surface area of the house. To do this, break it into simple geometric shapes and determine the area of each of them, and then fold it. From the received number you need to subtract the area of the door and window openings. This will help calculate the right amount of siding.

In order not to pay twice, reworking unexpectedly spoiled surface, you should pay attention to the products of famous brands.It is desirable that the manufacturer provides certificates and guarantees. Inspect your favorite samples: whether there are damages and cracks from inside and outside, whether the pattern on the panels coincides, and whether the thickness does not change.

When choosing metal siding, especially pay attention to the following characteristics:

- Panel thickness The larger the part area, the thicker it should be. Large panels of thin steel are easily deformed, which obviously does not improve the look of the coating.

- The thickness of the zinc coating layer. According to the standard, it should be not less than 20 microns, it is better to choose 25-30 microns.

- The material of the decorative coating. The best performance characteristics of Pural and PVDF. The latter has the ability to recover from minor damage. A more economical option is plastisol, but it burns out in the sun and quickly becomes dirty. A panel coated with polyester is better not to use for exterior decoration.

The size of the relief should be combined with the size of the building. Large masonry looks good on large buildings. A small house with a massive pile of cobblestones looks ridiculous. Decorative possibilities of siding under stone is wider than solid wall covering.Successful is the combination of walls trimmed with basement siding, smooth plastered surface and panels imitating wood.

You can come up with many combinations of panels with other materials. However, designers are advised to always make a clear boundary between the basement and the main part of the building. The difference may be in the color of the panels, the scale of their relief, decoration. Larger and massive parts are suitable for the lower part, lighter ones for the upper part.

Installation

The socle siding is installed in the same way as other types of this material.

Wall covering with insulation takes place in several stages:

- Inspection and surface preparation. The wall is cleaned of dust and mold, clean drains, rolling shutters and everything that complicates the installation process. Irregularities, dents and cracks are filled with putty, and severe damage - leveling plaster.

- Fastening crates - metal guides. If the wall needs to be warmed, the crate is installed in two layers: vertical and horizontal bearing. There must be at least 3 cm between the frame and the blind area of the building. This gap will compensate for the winter swelling of the ground and ensure the ventilation of the facade.

- Warming and waterproofing. Insulation is placed between the slats of the carrier layer close, and the slots are filled with foam. On top of the install waterproofing membrane. It releases warm, moist air from the inside, protecting it from moisture and precipitation outside. The film is laid overlapping, and the joints are fixed with adhesive tape.

- Installation of the counter-grille is a system of vertical bars on which the panels are mounted. In addition, it allows you to make a ventilation gap.

- Fastening angles, starting strips and window frames. Starts with the installation of the starting plate. It is strengthened strictly horizontally, on the selected bottom line. Then set the corner strips and window framing. When installing the basement siding H-slats are not needed.

- Panel installation. The work is carried out from the corner: the first part is cut vertically and fastened to the angular profile. After this, along the line of installation, one after another attach the following. The elements of the second row can be installed with an offset from the first, for this you will need to cut off half of the first panel.

When fixing the panels, it is important not to connect them tightly and not to tighten the screws as far as they will go, especially if the siding is made of vinyl.Gaps will make the design more mobile and durable, prevent deformation during the expansion of the material.

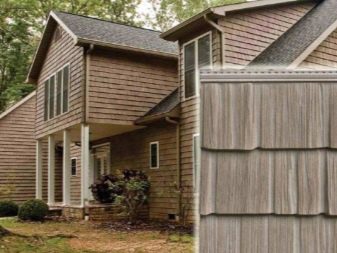

Beautiful examples

The combination of siding under stone and traditional facade. “Stone” decoration highlights the central part of the building and makes it more representative. Smooth plastered columns stand out against the background of the embossed stone surface.

Looking at this house, we seem to be transported to medieval Europe. The walls of a squat massive construction are sheathed mainly with basement siding, in some places a contrasting light surface is visible. The composition is completed with decorative dark beams.

An ordinary house is decorated with an unusual composition of siding. Monotonous "stone" surface of the wall is cut by inserts front panels, complementing its color and contrasting texture.

In this photo you can see a good combination of panels, repeating different types of stone. The base and pilasters are highlighted in dark, the details of the skin are divided into small uneven stones. The main sections of the walls are smooth light plates.

A good example of the use of panels with large relief for finishing a small house. Wide openings and an elegant roof make the building beautiful and reliable at the same time.

Sheathing siding is suitable not only for historic-style mansions. A modern minimalist building in the photo without finishing would look more simple. Notice how the light narrow strips of stone emphasize other horizontal elements.

Covering basement siding is an inexpensive way to give a home an attractive and neat look. The most universal panels of vinyl: they will update the old building, emphasize the beauty of a small cottage family mansion. The most accurate imitation of the stone surface can be achieved using fiber cement siding. A metal panel with a picture of a stone is used mainly for the basement and outbuildings.

In the next video you will find a house trim with basement siding under stone.