Features of the choice of outdoor insulation for the walls of the house under the siding

Facing the facade with siding has become widespread, in part because it allows us to make home insulation along with the cladding. What insulation is suitable for this purpose?

Special features

To improve the thermal efficiency of the house or other object, they most often resort to external insulation of the house. Compared to thermal insulation of walls from the inside, this method demonstrates better efficiency, and also allows protecting the facade from negative environmental impact and does not reduce the useful internal area of the object.

Naturally, the layer of insulation should be protected from negative environmental factors and hidden from prying eyes.The most popular is the technology of curtain walls, in particular, cladding with siding, which is a decorative wall panels.

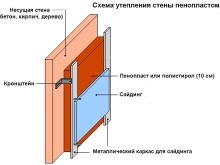

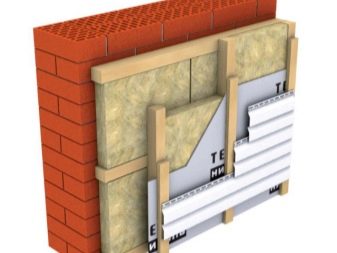

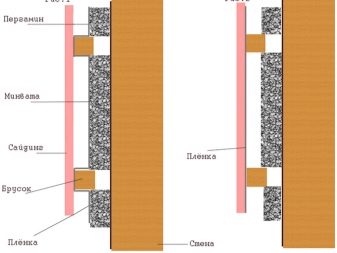

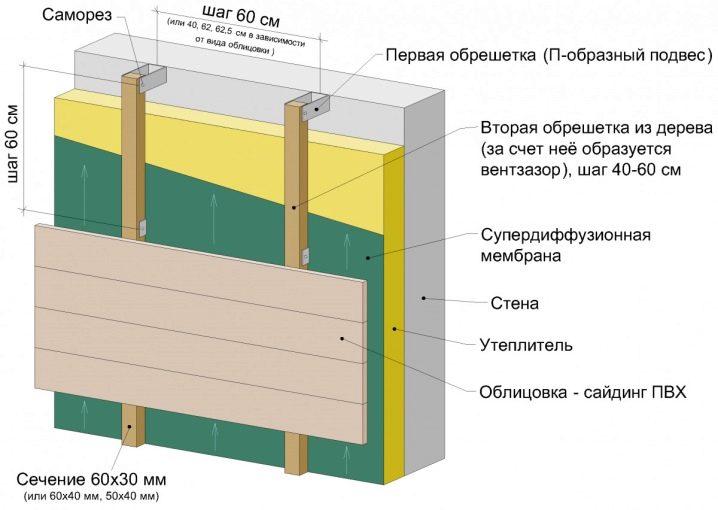

Sheathing in this way involves the organization of a ventilated facade. In general, the assembly technology is as follows - a metal or wooden crate is stuffed onto the outer surface of the walls, then a layer of insulation of the required thickness is laid, followed by a hydro-windscreen film, after which the siding is hung on the crate.

At the same time, an air gap of 3-5 cm thick is maintained between the panels and the insulation layer. It provides ventilation of the walls and insulation, as well as provides an additional insulating effect. Not every type of material is suitable for external insulation under siding, because, in addition to its low thermal conductivity, it must meet certain requirements - it must be moisture-proof, eco-friendly, and biostable.

Kinds

Among the most common types of insulation for siding should be a few.

Styrofoam

First of all, it is a well-known foam plastic.It has a high thermal conductivity, since it is formed by many tiny balloons. Despite its high thermal insulation properties, the material is less and less used, because it is environmentally unsafe (it releases hazardous styrene during operation), combustible (supports burning, releases toxins when the temperature rises), attracts rodents.

Modern modification is extruded polystyrene foam, higher technical characteristics of which are achieved due to the isolation of air chambers from each other. This increases the moisture resistance of the material, because it does not absorb liquid, and also increases its environmental safety and fire resistance.

The advantage of polystyrene heaters is also low weight, affordability and ease of installation. The material is produced in the form of sheets of different sizes, thickness and density, which are easily cut with a construction knife, glued or fastened with screws. The sheets have a smooth surface, so they fit snugly to the working base.

Mineral wool insulation

Another popular group of heaters, including slag wool, glass wool and stone wool. The first (slag) is not used for insulation, because it does not have the necessary characteristics.

The coefficient of thermal conductivity of mineral wool insulators is similar to that of polystyrene foam. However, heat retention occurs due to the structure of the material. Mineral wool insulation is a very long fiber, arranged in a chaotic manner. Air gaps are formed between these fibers, which provide the insulating effect.

Glass wool, which is based on molten glass breakage and quartz sand, is more elastic and soft, therefore it is suitable for finishing surfaces that are complex in configuration. Among the disadvantages are the tendency to absorb moisture, flammability (ignition temperature - 500 C), the need to use a protective suit, glasses and gloves during work (thin and sharp fibers penetrate the skin, causing irritation).

More expensive stone wool is a non-combustible material because it is made from molten rock. The melting point is over 1200 C. Among the advantages are higher moisture resistance. It is not pricked like glass wool, although when working with any mineral wool insulation a respirator should be used. Mineral wool is an environmentally friendly material. It is available in sheets, rolls, and if we are talking about high-density insulation, in mats.

Due to the peculiarities of the structure, the material is evenly distributed between the sheathing profiles, which eliminates the risk of "cold bridges". Finally, the mineral wool has good vapor permeability, therefore, it is considered the best option for insulation on a frame or wooden house.

Polyurethane foam

This insulation is sprayed onto the surface, which ensures reliable adhesion of the material and the absence of seams and gaps. It is characterized by high thermal efficiency, due to which, to achieve an optimal heat-insulating effect, a layer thickness of 2–3 cm is sufficient, as well as environmental friendliness, incombustibility, and moisture resistance.

During the deposition process, toxic elements are released. (evaporates as the polyurethane foam cures), therefore the application requires the use of a suit and a respirator.Among the shortcomings - low vapor permeability (therefore, insulation is not recommended to spray on wooden walls) and the need to use special professional equipment.

An important point - polyurethane foam, like polystyrene foam, is destroyed by exposure to sunlight. In this regard, it is impossible to store the material without packaging, and after installing the insulation should begin as soon as possible to install the hinged system.

Penofol

Foil insulation based on polyethylene foam. By itself, the latter has a low coefficient of thermal conductivity, however, a thin foil layer provides the main thermal efficiency of the material. It reflects up to 97% of the heat, so the insulation works on the principle of a thermos - it does not allow heat to leave the room during the cold season and maintains a pleasant coolness on a hot day.

Penofol is fixed with a foiled layer inwards and eliminates the use of additional hydroprotective materials. Among the advantages are a small thickness (up to 5 mm), low weight, high sound insulation performance. Release form - rolls.

Specifications

When choosing insulation for siding should consider several important parameters.

Coefficient of thermal conductivity

The main characteristic for insulation - the lower the coefficient, the warmer the object will turn out. This coefficient shows how much heat energy leaves after 1 m3 of heat at a temperature difference between the inside and outside of 10 C.

The lowest coefficient of thermal conductivity has polyurethane foam - 0.3 W / (m × K). Slightly more - 0.4 W / (m × K) polystyrene foam materials and mineral wool.

Hygroscopicity

This term refers to the ability of a material to absorb moisture. Hygroscopicity is directly related to thermal conductivity, since the wet insulation loses its insulating function. The best indicators of moisture resistance of the materials presented demonstrate polystyrene foam (especially extruded), polyurethane foam and penofol. If we compare the types of mineral wool, then basalt insulation is more resistant to the influence of liquids.

Vapor barrier

The ability of a material to remove water vapor until it turns into water droplets. The best indicators in this parameter are demonstrated by mineral wool, the worst - polyurethane foam.

Density

From the density of the material depends on its rigidity, strength.If we talk about mineral wool, then there is a clear relationship between the density and thermal conductivity. The more densely laid the fibers, the smaller the air gap between them and the lower the thermal efficiency. In this regard, more dense materials are thicker.

Fire resistance

One more parameter to which it is worth paying attention when choosing a heater. Basalt cotton wool and polyurethane foam is non-combustible. Some types of extruded polystyrene foam, penofol, are self-extinguishing. Such materials do not sustain combustion and do not emit dangerous toxins when heated. In cases where it is impossible to use non-combustible materials, it is recommended to combine fire-resistant panels for finishing with non-combustible insulation. For example, if non-combustible metal siding is used, it can be combined with combustible foam.

If combustible vinyl siding is used, then it is recommended to purchase non-combustible basalt or polyurethane foam insulation.

Environmental friendliness

With external insulation, this parameter becomes not as important as with internal insulation.From the point of view of environmental friendliness, stone wool, polyurethane foam and penofol are considered the safest. Extruded polystyrene is inferior to them in its security, but surpasses foam plastic in this parameter. In general, all considered options are allowed for use in residential premises.

For some users, simplicity of installation and soundproofing properties of materials are also important. The sound insulation effect is provided by all considered types of insulation, except for polystyrene foam. According to user feedback, it is easiest to install polystyrene foam and mineral wool materials in sheets. When laying the rolled penofol, it is necessary to cut and join the “lines”, which, although insignificantly, complicates the installation. For spraying polyurethane foam, you have to call specialists with the equipment.

Overview of the best manufacturers

It is possible to pick up the material corresponding to the declared characteristics, only on condition of purchase of original products from a reliable manufacturer. These include the Danish firm ROCKWOOL, engaged in the release of mineral wool insulation. They have a different density and form of release.

For private housing, you should choose the series "Light Butts" and "Light Butts Scandic." The first is designed for wooden facades, the second is suitable for walls of concrete, stone, bricks, blocks. The customers' trust is enjoyed by the French brand ISOVER, under which mineral wool is produced. These are usually rolls and sheets of varying thickness. A special feature of the manufacturer is a very fine differentiation of the material according to the method of application - for each section of the house and the features of operation there will be a modification of the mineral wool.

The German quality that has become legendary is demonstrated by KNAUF heaters (Germany). For private housing there is a separate product line - “Heat Knauf”. If we talk about a domestic manufacturer, then attention should be paid first of all to the TechnoNicol brand. Mineral wool and polystyrene foam plates are produced under this brand.

In the manufacturer's collection there is a facade insulation, polystyrene foam plates with a minimum number of unsafe components, as well as products with enhanced sound insulation performance. A large selection of foamed and extruded polystyrene foam can be found atdomestic manufacturers "Europlex" and "Penoplex". The latter produces only extruded modification.

How to choose?

It is necessary to choose material for thermal insulation taking into account conditions of its operation. When choosing any insulation material should be selected in accordance with what area you want to warm. So, it is not recommended to fasten polystyrene foam and polyurethane foam on wooden surfaces, as they will not allow wood to “breathe” fully. This will cause the walls to begin to accumulate moisture and rot.

For wooden houses it is better to choose penofol or mineral veil. However, the latter requires a high-quality waterproofing system, otherwise cotton wool will get wet. If we are talking about quite old facades with a small bearing capacity, then it is recommended to choose a lighter insulation, for example, penofol. The coldest concrete walls can be insulated with the warmest material - polyurethane foam.

To achieve the desired insulation effect, it is also important to correctly calculate the thickness of the insulation. Too thin a layer will not save from the cold, and will also cause a displacement of the “dew point” in the thickness of the insulation.As a result - its wet.

An excessively thick layer of heat insulator is an increased load on the supporting structures.as well as unreasonable financial expenses. When studying the fire hazard of a material, one should pay attention not only to the class of flammability, but also to the ability of the material to release hazardous toxins during combustion.

Regardless of the type of material chosen, preference should be given to well-known manufacturers, and before buying make sure of the originality of the product - ask the seller to present certificates of conformity. Insulation should be sealed, must not be soaked.

In this regard, it is better to shop at good specialty stores, and not in a tent on the market.

How to use?

Selecting the required insulation and calculating the required thickness, you can proceed to the installation of the material. As a rule, sheets of 3-5 cm are used for external insulation. If a thicker thermal insulation layer is required, professionals recommend using 2 layers of thinner materials, stacked one on top of the other. It is important that the joints of the first layer do not coincide with the joints of the second; for this, the second layer is laid with a slight offset.

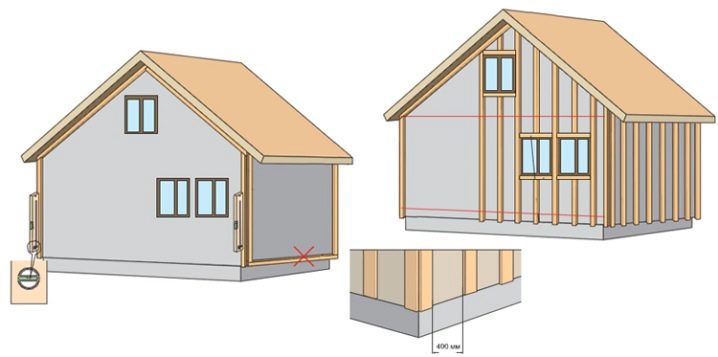

Preliminary preparation of the wall under the siding is not required. It is enough to remove interfering communications, repel a crumbling layer of plaster, eliminate large cracks and, if necessary, reinforce weak areas. Small defects can not be eliminated, as they will hide the crate.

Insulation for mounting the hinged system is attached after the crate is completed. It is assembled from metal profiles or wooden bars on the wall surface and is intended for fixing wall panels.

The width of the crate should be slightly less than the width of the siding. Insulation fits between the elements of the frame, that is, in its width, it is not much different from the width of the panels. Insulation is placed directly on the wall, if mineral wool is used and it spreads along a wooden surface, usually a layer of vapor barrier film is laid between them.

It is important to ensure that the heat insulator closely adjoins the elements of the frame, because otherwise gaps are formed, which then turn into “cold bridges”.

The insulation can be fixed first with temporary plastic screws, the length of which is 50 mm longer than the thickness of the material. Polystyrene foam can be glued to concrete or brick structures.A waterproofing film is laid over the layer of insulation. A more effective option is the use of a diffuse membrane.

The task of this layer is to provide vapor insulation and moisture protection of the heater.and in the case of using mineral wool materials - protect them from blowing. The film or membrane is overlapped, all seams are taped. In case of accidental damage to the surface of the film, these places also need to be glued. The next stage is fixing the insulation along with the film to the wall. Two layers are fastened with a single screw, 2–3 screws at the corners and one in the center are enough for a sheet of insulation.

Installation of a facade on this technology is completed by installing siding. The panels are mounted on the frame with galvanized screws or nails. An air gap of 3–5 cm thick is maintained between them and the layer of insulation.

Useful tips from the pros

With other indicators being equal, choosing between roll, sheet and insulation in mats, preference should be given to the last two options. Unlike rolled analogs, they are easier to fit. Mineral insulation should be laid in several layers.Polyurethane foam is sprayed after the installation of the batten, otherwise its construction will be impossible.

Although it is more convenient to mount the penofol before installing the batten, it is not worth doing so. First, penofol does not withstand heavy loads, and secondly, the foiling layer may crack and, as a result, it will lose its qualities. When stuffing penofol, it is necessary to go a little on the elements of the batten, this will ensure the most tight fit of the material. When installing foam polystyrene insulation, it is important to make sure that there are no traces of gasoline and acetone on the surface of the facade. Upon contact of this type of insulation with these components is its destruction.

If there are gaps between the sheets of expanded polystyrene, as well as in the places of their joints with the elements of the batten, you can fill them with assembly foam.

How to warm the house under a siding, look in the following video.