Types and features of wooden siding

The popularity of the house siding with wooden siding is due not only to the attractive appearance, but also to the functional features of this finishing material. Varieties, presented in a wide range, with both advantages and disadvantages, allow you to choose the most suitable option for finishing in each particular case.

Special features

Siding is a cladding panels, for which the construction of a preliminary support frame is necessary. Currently, the production of wooden siding debugged to the smallest detail both in Russia and in other countries.

The basis of manufacturing is the pressing of wood chip fiber under high pressure. Different manufacturers use their individual technologies and additives to give the tree a certain texture and color.

A house decorated with such material imitates a wooden structure or a log house and allows you to save on the construction of an actual wooden house.

Advantages and disadvantages

The use of wooden siding is common in any strip of Russia. At the same time, wood paneling is a choice not only of the owners of the houses themselves, but also of professional builders who recommend this material to their clients.

This is due to the following advantages:

- wood siding withstands precipitation and sunlight;

- has frost resistance;

- provides home strength and durability;

- easily tolerates sudden changes in temperature;

- has environmental friendliness;

- easy to install;

- gives an aesthetic appearance to the object.

The main plus is the possibility of mounting the panels not only vertically or horizontally, but also at an angle.

Despite the many advantages, when buying a wooden siding should take into account some of the disadvantages:

- high degree of ignition;

- wears out under the influence of moisture, therefore, requires careful maintenance;

- it is a natural natural material, and therefore its value is not available to everyone.

Summarizing the pros and cons, we can draw the following conclusion.Wood siding is suitable for exterior decoration in the northern latitudes of the country, it will perfectly withstand temperatures of 50 degrees below zero. But the material is not recommended for use in the southern regions due to high temperatures, as it is easily flammable. In order to prevent rapid wear, it is necessary at least once a year to treat the surface with waterproofing impregnation.

Species

There are two types of wood siding - false bars and block house. Each of the options has its pros and cons.

Block house

The facing block house is intended to imitate a planed log, that is, it has a convex shape. It is more often made from traditional breeds of wood.

Products from this group are divided into the following classes:

- class A;

- class B;

- class C.

Class A wood It is considered the highest quality, but it costs more than other varieties. On one plank, a maximum of two small cracks are allowed, and on one and a half meters of length, only one bitch is allowed. Perhaps the presence of several Sernitz

Class B wood admits a maximum of four bitches at 1.5-meter length and 2 shallow cracks. The number of resin pockets - no more than two.

Last class C the least quality, it may contain knots with a diameter of 25 mm, it is possible the presence of two through cracks. On the five-meter square there can be pockets of up to 50 mm in size.

Raised beam

In the domestic market, the material appeared relatively recently. It is a covering board. Allows you to create perfectly smooth facades. It is used both for internal, and for exterior finish.

It is divided into the following classes:

- class A;

- extra;

- class AB;

- class B;

- class C.

Classes A and Extra belong to the highest. They have a perfectly flat and smooth surface, no more than three knots are allowed. Mechanical damage on such wood should not be. The cost of top grade is not available to everyone.

Class AB, implying a combination of varieties A and B, admits the presence of small resin pockets of no more than 3 mm. The presence of two knots per meter of length and microcracks is possible.

U class wood minimal disturbance of the geometric shape is allowed. Allowable cracks and chips up to 0.5 mm in depth, small errors in polishing. On the front side there may be more than three knots, more than two pockets are allowed.

Class C can be with loose knots, damage in the spike or groove. A lot of resin pockets, chips. Class C wood is inexpensive, but with skillful installation it looks pretty decent.

Raised bars can be made exclusively at the factory. The most valuable are products from pine and Siberian larch. They are durable and durable, do not allow the reproduction of fungus and insects, have an exquisite natural pattern. And also false bars can be made of tropical trees.

Materials

The most common materials for the manufacture of wood:

- Pine;

- cedar;

- larch.

Pine

The most popular option. Used for cladding buildings. The material is quite reliable and hardy, resistant to the reproduction of harmful organisms.

It has the following advantages:

- not subject to temperature extremes;

- a large amount of resin provides moisture resistance;

- pleasant aroma, beneficial to health.

Nevertheless, there are in this variety and disadvantages. The abundance of resin leads to the fact that it begins to stand out on the surface, it reduces the aesthetic qualities.Therefore, pine is not suitable for interior decoration; over time, the material becomes reddish.

Cedar

Cedar wood is resistant to cracking, and also able to produce volatile production, useful for people suffering from lung ailments. Especially currently valued Canadian cedar. This is a relatively new option, but in the short time since its appearance it has managed to gain widespread throughout the country.

Advantages of Canadian cedar:

- suitable for outdoor decoration of all types of objects due to ergonomics and durability;

- has good heat and sound insulation performance;

- creates a spectacular appearance due to the wealth of structures and warm colors;

- It has a very democratic value.

This type can be used for lining houses and cottages, as well as serving as interior decoration for baths and saunas: the material withstands the negative effects of moisture and temperature changes. Of the minuses of Canadian cedar, it should be noted its inaccessibility in many regions, as long as it is considered a novelty.

Larch

The most expensive finish option.But its elite status is justified by its excellent strength and durability. The main advantage of larch - the breed is not exposed to the negative effects of moisture.

Other benefits:

- resistance to cracking;

- versatility - suitable for covering concrete, brick, timber;

- good fire resistance;

- resistance to temperature extremes;

- esthetic appearance;

- environmental friendliness.

The material is used both for internal lining of surfaces of walls and ceilings, and for external facade decoration of any buildings and structures. Among the disadvantages of the product is the high price and the possible release of the resin over time, this is especially true when operating in a warm room or a hot climate.

New items

Currently, the range of wood is very diverse. Among the novelties attention deserves the Finnish siding, including spruce and pine. This option is widely used as a finishing material for walls, ceilings, facades, has an affordable price and is distinguished by quite decent quality for Russian operating conditions.

Among the new products can also be noted meranti wood siding. This tree is mined in Indonesia and Malaysia. Due to the abundance of tannins and resins, this option in comparison with coniferous woods does not absorb moisture and almost does not rot. Differs wear resistance, beautiful color - from brownish-pink to brown. This species is more often used to produce imitation timber.

Installation rules

Installing wooden siding is an easy process, but it is still better to entrust it to professionals.

If you plan to self-assembly, it is worth following a few rules.

- Installation is possible in any season, but performing work at low temperatures (below -10 degrees) requires special technology.

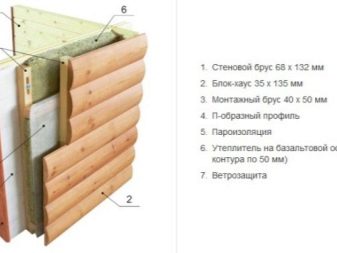

- The insulation is created in the following order: first the vapor barrier is laid out, then the sheathing, then the thermal and waterproofing.

- The panels need to be fixed only with galvanized products, otherwise the wood may start to rot.

- Hard attachment should not be. The panels are connected only in specially designated areas, as under the influence of temperature they will “walk” and can be damaged when rigidly mounted.

- Leave a gap between the guides and the main strips so that the siding does not arch and also for ventilation. The recommended gap size is 10 mm.

Wood siding can last for a long time, but for this it is necessary to annually treat it with special decorative protective compounds.

Despite this drawback, wood panels are one of the most common options for cladding facades. This is due to the possibility of non-standard and simple installation, elegant appearance, special natural aroma, as well as a wide range of varieties, including both budget siding and luxury options.

How wooden siding is mounted, see below.