Ground siding under stone: the pros and cons

Experts from the construction industry say that the basement is the most vulnerable element of the building. That he has to constantly experience various vagaries of weather and stress. Temperature fluctuations, ground dips, high humidity and other factors can deform this element.

For the finishing of this part of the house is used ground siding. This is a separate type of finishing material, which is a facade cladding. The most popular lining under the stone. Let us examine this type of finish in more detail.

General information

The basement siding, which is also called the technical equipment, not only decorates, but also protects the structure, taking on the load from precipitation, flooding and other external influences. A stylish and attractive finishing material that imitates a natural product, ideal for decorating the exterior of private houses and cottages.

Products are offered to customers in the format of panels of various sizes. Manufacturers offer standard dimensions, as well as custom-made items. High-quality material successfully combines functional and decorative properties. Siding has many positive qualities, which we will read later in the article.

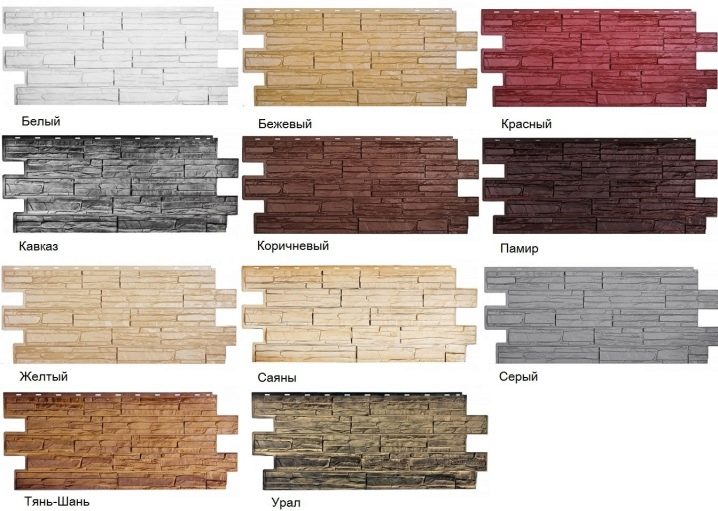

The modern market of building and finishing materials offers a wide range of products, differing in appearance and performance characteristics.

Lining features

The main task of this finishing material - facing the lower part of the structure, which lies on the foundation. The main sphere of use is the design of wooden houses with a stone base. The stone material masterfully imitates the texture of a wild stone and its original coloring.

A distinctive feature of the product is a wide dimensional grid compared to the standard cladding. This is due to the texture features of the copied material.

The masonry is assembled from individual fragments that fit snugly together. Only elements can be fastened along a special connection line. For more convenient mounting manufacturers have thought out a special form of siding sheets.

If necessary, you can use the casing of various sizes, creating an amazing and expressive decor.

It should be noted that the popularity of this option on the territory of Russia has just begun to grow. Now this design is in great demand in Europe and America. Major brands offer customers a variety of imitations of various types of stone.

Advantages and disadvantages of the material

After analyzing the reviews of real buyers, informational articles, as well as expert opinions, a list of positive product qualities was compiled.

Pros:

- High-quality imitation of various types of masonry from natural stone. Visually determine the difference is almost impossible.

- A wide range of flourishes and textures.

- Excellent aesthetic qualities. With the help of cladding, an ordinary building will turn into a house from a fantasy movie or fairy tale.

- High technical characteristics, including practicality, wear resistance, long service life and reliability.

- A simple process of laying material, due to which the work can be carried out without the involvement of specialists and at any time of the year, regardless of the temperature outside the window.

- Convenient dimensions of the panels, so that stacking can be done alone.

- Environmentally friendly material is completely safe for health and resistant to the formation of fungus, mold and other things.

- Favorable cost available to the average Russian consumer. For relatively little money, you can significantly change the appearance of buildings, without changing their architecture.

To fully deal with this option facing, It is necessary to familiarize not only with positive, but also with negative properties of products:

- Some siding models can not boast of fire resistance. In case of fire, the material will begin to melt, possibly a fire.

- At low temperatures, plastic panels lose their elasticity and ductility. They become brittle and can easily break under load.

- In the process of laying it is necessary to take into account the increased coefficient of thermal expansion and take appropriate measures.

- When using various product options, you run the risk of creating an overly bright and colorful facade that will destroy the integrity of the exterior.

Specifications

The performance characteristics of the products depend on the manufacturer. Each company uses certain techniques and compositions in the production process.

Despite the differences, there are general parameters:

- Length. This figure varies from 950 to 2000 millimeters. Some brands make panels to order in the amount of up to 6000 millimeters.

- Width. The minimum value is 400-450 millimeters. Maximum - 630 millimeters.

- The period of operation is approximately 30 to 50 years. This indicator depends on the quality of the material and the climatic conditions in the region.

- The temperature mode of operation of the panels ranges from 50 degrees Celsius to 60 degrees with a plus sign.

- The relief of the cladding can have a height of from 12 to 25 millimeters.

- The average thickness of plastic siding is 1.2 millimeters. Metal panels - from 0.8 to 1 millimeter.

The size of the finishing material substantially depends on the brand and the specific collection. Included with the facing panels are the corners and finishing strips for fastening (profiles). You will learn how to install the basement siding under the stone, from the following video.

Species

"Stone" siding is divided into groups depending on the material from which it is made.

There are four categories:

- vinyl

- acrylic

- fiber cement

- metal

Each product has its own specific characteristics and properties.

Vinyl

For the manufacture of panels using a synthetic material polyvinyl chloride. The main advantages of the products are excellent resistance to corrosive processes, rotting, as well as high temperature.

High-quality finishing material is not afraid of the vagaries of the weather, due to which it is recommended to use in regions with a changeable climate.

The average lifetime of the panels is about 40 years. Despite the fact that artificial raw materials are used for its production, it is an environmentally friendly material that does not emit hazardous substances during operation. The material is lightweight and non-combustible. The cost of products is profitable, due to which vinyl siding has become widespread.

A slight mechanical impact will not spoil the shape and beauty of the finish.

As disadvantages, experts point out low resistance to long and intenseloads. Prolonged exposure to high temperatures leads to deformation of the finish.

Acrylic

This type of lining has some similarities with the first class. Polymers are used for their manufacture. However, significant differences do exist.

Siding features and differences from vinyl products:

- Sharp changes in temperature parameters will not affect the quality, strength and appearance of the panels.

- Acrylic finish tolerates high temperatures. The maximum figure is 385 degrees Celsius above zero.

- Due to the improved technical characteristics, the cost of this product is higher compared to vinyl siding.

- The product is not affected by various chemical elements.

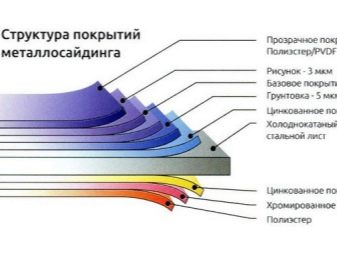

Metal

For the production of this category of products used galvanized steel. It is a durable and reliable material that retains these characteristics for many years of operation. So that the material does not rust, it is treated with special protective compounds. Among the positive characteristics of the panels emit that they are absolutely resistant to fire and the process of decay.

The large weight of the material complicates the process of its installation. Experts do not recommend working alone, especially for people with no experience. Also worth noting is the increased cost compared to the two options above.

Fiber cement

In the manufacture of products, the company uses as the main element cement and various additives, among which are special fibers for reinforcement. Components are securely interconnected by pressing. The main advantages of the product are excellent strength, provided that no errors were made during the manufacturing process. Also noted resistance to climate change, elevated temperatures and open fire.

The disadvantage is the complexity of the installation. When using fiber cement siding will not be able to block the seams of the connection panels.

Due to the fragility of the material, the panels should be transported as carefully as possible so as not to damage them. Strong mechanical loads will simply break the panel.

How to choose?

Before you go to the store for finishing or make an order via the Internet, you need to know what to look for when choosing it.First of all, it is necessary to determine the purpose of the lining. If you choose a product exclusively for the lower part of the building, the coverage area will be small.

Also consider the possibility of various damage in this area. The basement of the structure has a lot of contact with the outside world and foreign objects. The practicality and durability of the product depends on the raw materials of the panels.

Specialists have made a number of recommendations that will help make the right choice among a rich assortment.

Basic rules of choice:

- If you want to focus on the appearance of the finish, it is desirable to abandon the panels with a small pattern. The smaller it is, the worse it will be visible in the mass.

- In order to achieve maximum naturalness and naturalness, stop the choice on lining in natural colors. Bright and saturated panels attract attention with bright colors, but they do not always look good in the end.

- Examine the performance characteristics of products of different types, as well as the advantages and disadvantages of its use. Match the data with the climatic conditions in the region and make the right choice.

- Building and finishing materials stores offer domestic and foreign products. If you decide to purchase an imported product, pay attention to Canadian siding. This product has proven itself in the Russian market.

Stone ground siding is available in a wide variety of colors and textures. Each collection has a special visual effect.

The most popular are such positions:

- "Antique" siding - ideal for antique and ancient stylistics. Currently, this finish is considered a classic and is always relevant.

- If you want to decorate the house with imitation of rough rocks, pay attention to the finish "rubble stone".

- A distinctive feature of the "torn stone" is an expressive rough texture.

- For fans of elegance and refinement manufacturers offer imitation of marbled.

- In the manufacture of panels of the type "old hand molding" experts use the effect of aged brickwork.

- The material that copies natural granite is in great demand. This is one of the most common options.