Plastic panels for walls: features of choice

If you want to quickly and cheaply improve the appearance of such interior spaces as the kitchen, bathroom unit and corridor, then you will not find a more profitable and effective way than the installation of plastic wall panels.

Repair work with the use of PVC can be done independently without recourse to the services of professional finishers, but this requires at least minimal construction skills and time.

Features and benefits

Polyvinyl chloride wall panels are a finishing material that won the trust of consumers many years ago.The main component of the panels is solid and strong, but at the same time light PVC, so that the lining can be carried out in office buildings and shopping complexes, and in living spaces.

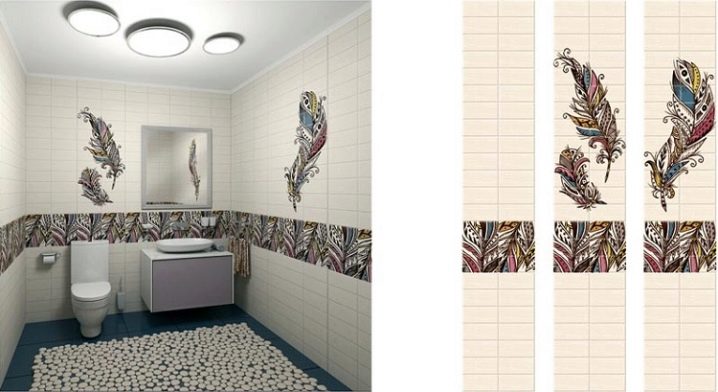

In houses and apartments, this material is usually used for decorative decoration of areas with high humidity levels. - namely, for kitchens and showers, the use of plastic is also justified in the corridor, where shoes constantly stain walls, and any other material quickly becomes unusable.

For the manufacture of wallboard used phenol-formaldehyde resins, which are completely harmless to the body of children and adults, and for the dyeing of plastic lining used water-based paints, which also do not contain any harmful and toxic to humans components.

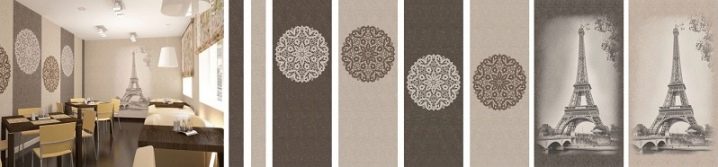

The modern market offers the broadest selection of panels that differ in color, texture and shape. Such a wide choice allows you to use plastic cladding in rooms of various purposes - from the toilet to the dining room and the hall.

The high popularity of this type of facing materials is explained by a number of advantages of plastic wall panels, among which may be noted:

- Universality of coverage. Traditionally, such panels are used to finish ceilings and walls, but the structure and physical and technical parameters of the material allow it to find a lot of other uses: trim slopes, decorate screens in bathrooms and showers, design formwork for the steps, many craftsmen even make shelves from such panels, And gardeners often form beds from plastic lining in their gardens.

- Easy installation. Even a novice master can cover the wall with such panels, especially when you have to work with a flat surface - then the plates simply “put” on liquid nails, but to mount the panels on a curved surface, you will need to pre-fix the batten, but these works do not require much effort and of time.

- Ease of care. Plastic coatings are easily cleaned with a damp, soft cloth that is soaked in soapy water.

- Environmental friendliness. The panels are made from non-toxic materials, they do not contain volatile substances, do not emit radiation.

- Fortress. For wall cladding manufacturers produce compacted materials, so that they can withstand shocks during the rearrangement of furniture or games of young children.

- Sound and heat insulation.PVC panels create an additional thermal protection in the room and have noise absorbing properties.

- Resistant to moisture. Plastic has water-repellent properties, the water absorption coefficient approaches zero and at the same time due to the smooth surface the water does not stay on the tile. It does not form molds, fungi and other pathogens do not reproduce.

- Resistance to temperature fluctuations. The working range of the panels is large, they withstand temperatures from -50 to +50 degrees, without changing their consumer properties.

- Wide range of. Panels are offered in stores in a wide variety of colors.

However, the panels are not perfect, like any other building material, they have their drawbacks:

- PVC panels are not resistant to UV rays. If they are painted white, then over time they will turn yellow and lose their original gloss.

- Weak impact resistance - naturally, the loads of weak and medium panel strength can withstand, but there is always the risk of dents that cannot be straightened.

- Unpleasant smell - some reviews claim that at the first time after the installation of the plates a chemical smell is noticeable, however, after a few days it completely disappears.

Species

An important factor that should not be neglected when purchasing wall panels is their size. Depending on the width of the plates, there are several coating options:

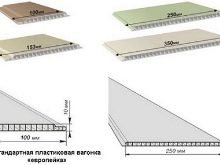

- Plastic lining. These are narrow and long panels. Similar lining is widely used for internal and front finishing works. Externally, the coating looks like something between a lining of wood and polycarbonate.

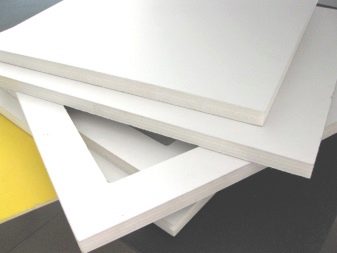

- Sheet panels. These are panels that have a width of up to 203 cm, and the length of the plate reaches 405 cm. Typically, these plates are made of polyvinyl chloride foam, some manufacturers additionally treat the surface with special compounds, making the plates more durable and wear-resistant. Sheets are laid on the walls with liquid nails or special glue, and all the gaps are masked with a rail or colored sealant.

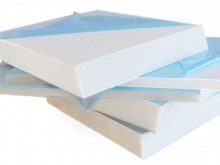

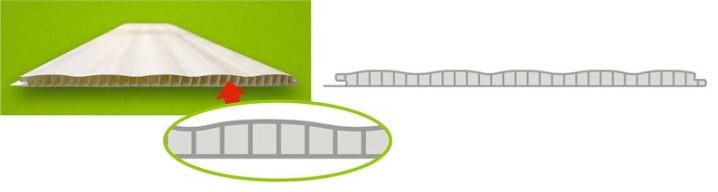

- PVC panels. In a separate group of wall plates made of plastic can be attributed to their kind, such as PVC sandwich panels. This type of coverage has relatively recently appeared on the domestic market, however, it immediately became one of the top sellers due to its high operational properties.Technically, these panels look like two sheets of plastic, between which there is a filler. They can act as polystyrene foam or polyurethane foam.

Depending on the material from which the outer layer is made, emit:

- Laminated Panels - such a coating is formed by the arrangement of paper of three types: decorative, which is responsible for product design, kraft paper, which makes up the inner layer and overlay, used to protect the panel. All layers are impregnated with special formaldehyde resins and pressed. Such plastic is considered to be the most reliable, since it can withstand high loads.

- Foamed sheets - such products are distinguished by a porous structure with high moisture resistance and good thermal insulation. As a rule, their surface is rough.

- Hard sheets - such products, despite being classified as wall panels, are in most cases used for cladding window and door slopes. Usually they are performed in a white version with a matte or glossy glossy surface.

Wall panels are vinyl, with insulation and without, square or rectangular, thin and thickened, embossed and smooth.

Specifications

Flexible wall panels are characterized by the highest operational parameters, which determine their popularity among Russians. These plates can retain their appearance and physical indicators for more than ten years, and the initial properties do not change either in hot or cold climates, maintaining temperatures from -50 to +50 degrees.

At the same time, experts advise against using such materials in conditions where the temperature difference exceeds 20 degrees; therefore, they should not be installed in unheated rooms in regions with hot summer months and frosty winters. Some manufacturers produce models whose temperature range is different and ranges from -40 to -115 degrees.

The production technology can significantly increase the wear resistance of the material, its antistatic effect, resistance to direct sunlight, as well as increased resistance to scratches, exposure to ash or chemical reagents.

Panels are not afraid of water, so they are often installed in rooms with a high level of humidity (bath, shower, pool), and thanks to their cold resistance, they can be used for cladding balconies and loggias.In addition, the panels are easily cleaned of all types of pollution, and this leads to their popularity for laying in the hallways and utility rooms.

Sizes and shapes

One of the main advantages of the material is associated with a wide range of its modifications presented on the modern market. There are a lot of facing materials, and they differ not only in color and texture, but also in dimensions, shapes and constructional parameters.

As already mentioned, depending on the size, there are several options for panels. Lining is elongated rectangular-shaped sheets, their length varies from 3 to 12 m, and the width is in the range from 0.1 to 0.5 m. The thickness of such a panel is 8-12 mm.

Plastic sheets have a length of 1.5 to 5 m. This parameter varies from different manufacturers, the width reaches 2.03 m, and the thickness gauge is up to 3 cm. The sandwich panels are 3 meters long, and the width is from 0.9 to 1 , 5 m and thickness from 10 to 32 mm.

Sometimes, for the realization of interior pans, seamless panels are taken, after installation of which the coating acquires a uniform and perfectly smooth appearance. Today, manufacturers offer similar products with a length of 2 to 6 m, a thickness of 3 to 12 mm and a width of 0.2 to 0.33 m.

Colors

For a long time, wall panels were made in a single white version. However, the market gradually moved away from the accepted standards and bright panels of various colors came to replace the monotonous materials: beige, cream, light green, blue, pink, purple and even black.

Every major manufacturer is trying to offer consumers at least 10-15 color solutions., so that anyone can choose the option of plates that will be optimal for the implementation of its design concept.

Often, wall panels are made in several shades or even with a pattern. Of course, the classic version of white is still relevant, although current trends increasingly suggest using it not solo, but in combination with other brighter shades.

Decor options

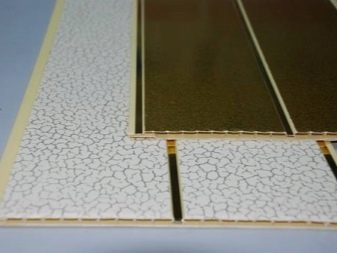

As a rule, a decorative pattern is applied to the surface of wall tiles, usually using offset, pad-printing or thermal printing methods, as well as lamination, after which the surface is treated with special varnishes.

According to the type of coating panels for walls can be mirrored, marble, "under the wood", "under the brick", reminiscent of wallpaper. In addition, they are openwork, embossed, fluorescent. In recent years, panels with a 3D effect, which imitate the relief of natural stone or brick, are very popular. Many manufacturers offer panels with photo printing.

Overview of popular manufacturers

When purchasing any product, you should first of all pay attention to the manufacturer, since the company's reputation often more than other factors indicates the level of product quality. And wall panels were no exception. Today, there are more than a hundred manufacturers from Russia and foreign countries working on the market. Let us dwell on those whom consumers have recognized as the best.

Venta - is a manufacturer from Belgium, which supplies its products worldwide. The panels of this brand are in stable demand in various countries. The company is constantly creating new plants and factories. So, in the early 2000s, the representation was opened in our country, which is why Russian buyers were able to purchase products at an affordable price.

In the product range of the brand a large selection of panels of various shapes, colors and textures, and the list of products is constantly expanding.Not so long ago, the production of panels with digital printing was adjusted, such products are decorative, aesthetic and can decorate absolutely any interior.

Forte - is an Italian brand that has been successfully selling its products since 1969. This company has become one of the largest in the world in terms of PVC-panel production. Today, products of this brand are sold in 50 countries, while the company's engineers are constantly introducing and improving production technology, optimizing the quality control system and introducing new versions of decorative panels.

The assortment line includes more than 20 colors and textures, a separate direction is the production of a line of panels with stone chips sprayed on the surface - such products look stylish and highlight the impeccable taste of homeowners.

Deceuninck - an international brand that was originally created as an association of a French and British company, but over the years of its work, it has significantly expanded its geography. Today, the company has 14 factories in different countries of the world, and the products are sold in 91 countries, including Russia.

Shanghai Zhuan. Chinese manufacturers are rapidly seizing the market, this applies to absolutely any direction, and the production of wall panels is no exception. It is noteworthy that the quality of the manufactured products is constantly being improved while prices remain affordable for the domestic user.

Green line - This is a Russian company, which is located in the city of Vladimir. Raw materials for the production of panels are purchased in Europe, so the products are of high quality, reliability and environmental safety. The specialists of this company pay the greatest attention to the reliability of the joints, since they have an impact on counteracting moisture ingress under the coating.

"Planet Plastic" - Another domestic brand from Moscow, which has been operating in the market since 2001. All production work is carried out on imported equipment from European raw materials, this allows us to speak with confidence about the high quality of the materials produced. It should be noted that the production of panels is the main activity of the company, so its specialists are constantly working to improve the technology of applying decorative coatings, today the plates of this brand are produced in 150 varieties.

"Evroplast Service" - this company has been operating in the facing materials market since 2005, the basis of the technological process is the European quality control system.

"Ural-Plast" - a manufacturer from Magnitogorsk, which, like other domestic enterprises, operates on foreign equipment. The company produces a large range of panels, while in addition to the standard options, the product line contains products with an exclusive design.

How to choose?

There is no doubt that when buying wall panels everyone wants to get a practical, high-quality and durable material that will last for many years, allowing you to forget about the repair. To make dreams come true, you need to pay close attention to a number of performance characteristics:

- Front panel size - it is considered that the thicker it is, the better, since it is from this indicator that the wear resistance, strength and duration of use of the plate largely depend. Obviously, if a plastic panel can easily be damaged, then moisture will penetrate through cracks and chipping, causing the appearance of spores of fungi and the propagation of mold.Of course, a panel that will withstand a blow with a hammer or a brick does not exist, but it should ideally be able to cope with the majority of not so significant loads.

Experts recommend to give preference to models in which the front tile is not less than 2.5 mm in thickness, while this parameter in most cheap modifications is about 1.5 mm.

- The number of ribs - here the principle and dependence is the same as in the previous case: the more, the more reliable. The number of stiffeners determines the susceptibility of the tile to deformations, so ideally there should be no less than 20, and best of all - 29. Separately focus on their appearance - the ribs should be smooth and have the same width along the whole length, and besides, the location must be strictly perpendicular to the tiles connecting them.

- Appearance - high-quality panel has a uniform color, it does not show dents and ribs, in addition, before the final purchase it is worth checking how firmly the panels are attached to each other.

- Weight - This parameter indicates the quality of the proposed product indirectly, but, nevertheless, is an additional sign of good and practical coverage.The larger the panel has stiffeners and the thicker its outer panel, the more it weighs. Such a parameter may be needed in the event that before you are two identical external plates, but having different weights.

Experts recommend buying products from the same batch, because in this case you can be sure that the pattern, shade and texture will be identical. Even in the conditions of one production, with the general article, the product may differ slightly in different batches, and if during the selection of the product it does not catch the eye, then after facing it is quite noticeable.

Instructions for use

Facing by plastic panels can be made in several ways. The simplest method is frameless lining; in this case, the panels are attached directly to the walls with glue or liquid nails.

This method is optimal if it is necessary to fix the panels on a flat surface., while the adhesive composition is applied to the surface with a trowel with teeth, after which the panels are alternately fixed tight pressing, butt joining with each other.

But if the surface is uneven, then installation of the batten will be required, on which the panels will already be fixed.As a rule, it is equipped with wooden slats, which are vertically mounted on the wall in 40-50 cm steps, and panels are already glued to them. Note that in rooms with high humidity frameless method does not apply, even if the walls are perfectly smooth. Places joints, as a rule, mask foam plastic.

What can be painted?

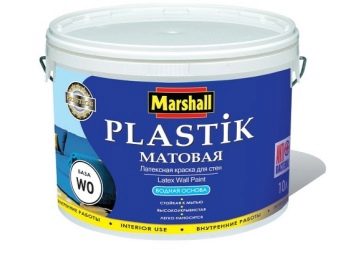

Sometimes homeowners have a desire to repaint the panels - this happens if the color has faded or is simply tired. Not every paint is suitable for staining; professionals recommend using aqueous polyurethane-acrylic dispersions. They do not contain solvents, therefore do not emit volatile substances, do not give a strong odor and are safe for humans.

At the same time the covering turns out decorative, iznoso-and waterproof. The service life of such paint is 7 years. All paints for the panels are made in white color, so before starting work it is necessary to purchase a color scheme and paint the coloring composition.

Please note that the repainting of the plastic surface is made strictly by spraying, since the manual method of painting will leave stains, drips and marks from the paint brush.

How to care?

The eternal problem inside the house, which all the housewives tirelessly struggle with, is dirt, while the epicenter of the “fighting” becomes the kitchen, bathroom and corridor, which are more often and heavily polluted than other rooms. At the same time, if, for example, in the hallway dirt is usually easy to clean, then it is much more difficult to clean the kitchen walls - plastic drops of fat along with dust particles that leave unpleasant stains that are not so easy to get rid of.

To clean wall PVC panels, use washing powder or other cleaning powder. Many people use dishwashing detergent or simple soap solution. All work should be done only with a sponge or soft cloth. The use of pumice or scrapers is strictly not allowed, as it causes damage to the coating and deterioration of the appearance. For the same reason, it is not recommended to strongly rub the place of pollution - it is enough to put a cleaning agent on it, leave it for a short time and easily wash it off with warm water.

Also, do not use aggressive compounds that contain alkalis and acids.

Harm and Benefit

There is an opinion that plastic wall panels are dangerous to human health. If you address this question to professionals and manufacturers, the answer will definitely be negative - all materials are completely non-toxic and environmentally friendly. This is true - wall panels are made from high-quality raw materials that have undergone multi-stage control and expertise.

Plastic panels are widely used in the finishing of medical and kindergartens, and it is better than any words testifies to their safety. However, the modern market today is literally flooded with a large number of counterfeit goods, the quality of which is in serious doubt.

Note that the panels can be harmful only if they were produced using low-grade adhesives, paints and varnishes — for any increase in temperature, they begin to emit dangerous volatile substances. That is why the first thing that needs to be done at the time of purchase is to request a certificate from the seller and pay attention to the description of paintwork materials that were used in the manufacture of plates.

An indirect sign of a poor-quality product is its cost - usually too low a price suggests that, perhaps, the products are made in violation of sanitary standards.

Beautiful examples in the interior

- Plastic panels are ideal for corridors and hallways.

- In bathrooms often prefer this material.

- By the way, some paneled even living rooms and bedrooms.

- A very popular solution is the cladding of balconies and loggias with plastic plates.

In the next video you will find one of the ways to install plastic PVC panels.