Installation of PVC panels: installation guide

If, while putting the apartment in order, there appeared a desire to move away from the usual wallpaper and not to get involved with ceramic tiles, then you can turn your attention to the finishing of the walls with PVC plastic panels. Installation of such a coating is very simple, it can be done independently, without resorting to professionals. Moreover, this material will perfectly fit into the interior of the living room, and corridor, and bathroom, and even a balcony.

Training

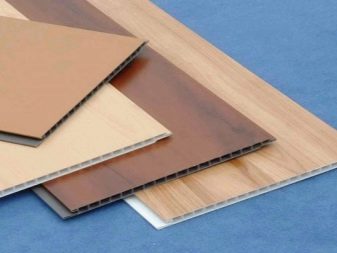

PVC is polyvinyl chloride, simply, a kind of plastic. Panels made of this material are particularly popular because they are not afraid of moisture and do not rot, quickly assembled, do not change under the influence of ultraviolet rays, for a long time retain a decent appearance and, when using the frame, create additional sound insulation.Finally, they are relatively cheap.

Installation of PVC plastic panels always begins with a preparatory stage. First, the material is selected and purchased with respect for several important points. Being in the store, you need to inspect the cut panel. If there are thick layers, both external and internal, and a thick web, then the finish will be reliable. Panel thickness can also be determined by weight - the heavier, the thicker. Then the plastic uniformity is examined. The entire sheet should have a uniform thickness without too thick and too narrow places - this is a guarantee of good quality.

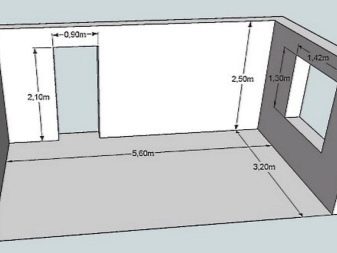

When a brand and a manufacturer are chosen (it’s better to turn your attention to European firms), you also need to calculate how much material is needed. Otherwise, there will be unused fragments (and will be overpaid), or vice versa, the material will not be enough and you will have to urgently buy it in the store (excessive time will be spent). PVC panels are placed either vertically or horizontally. In the first case, it is necessary to measure the length of the room along the perimeter, then subtract the width of the doors and windows from this figure and divide the remainder by the width of one panel. Get the number of elements required for the repair of the room.To this figure, it is better to add a couple of units in case of unforeseen situations.

If the panels are placed horizontally, the area of the room is calculated first. Following from this figure is deducted the area of doors and window openings. Finally, the resulting number is divided by the area of one panel (usually this figure is indicated on the packaging by the manufacturer). 10% is also added in case of unforeseen situations. If the sheets are mounted horizontally, then you should be prepared that the material will have to be cut out, which means that trimming will remain.

By getting rid of the packaging, you can carefully see the edges and individual cells. There should be no dents or damage to the panels. The more complex the image, the more important it is to study the quality of its deposition - vigilant fragments and uneven coating should cause caution. Also, if you have to purchase several packs of sheets that should match in color, it is reasonable to unpack and check whether the shades converge. Finally, the material should be tested right in the store. One sheet is bent about 30%, and then unbent.If there is no damage, then everything is fine with the purchase.

By purchasing the material, you must prepare the walls. The first step is to remove the old paint, tiles, wallpaper and layers of the old finish. Then level the surface with plaster. In addition, it would be nice to try to seal the existing grooves or to eliminate the protruding elements. Having completed with the alignment of the wall, you can proceed to the primer. It is recommended to choose a composition with additives against mold and mildew. While the primer dries, you can do the assembly of the batten and also bring the panels into the room - they need to stay inside for about 12 hours in order to adapt to the existing conditions.

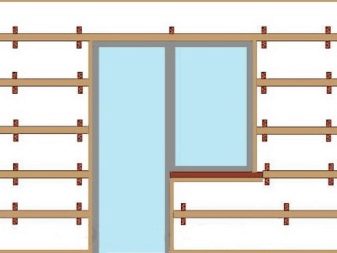

The elements of the batten should be perpendicular to the plastic sheets. This means that if the crate goes horizontally, the panels will go vertically and vice versa. The distance between the battens should be from 30 to 50 centimeters, the first digit is still optimal. Planks to be fixed near the window openings, near the doorways, as well as at the beginning and end of the wall.

The crate is most often attached to the dowel.The length for the concrete wall is 40 millimeters, and the brick one is 60 millimeters. The distance between the dowels varies from 50 to 60 centimeters. In order for the PVC panels to be evenly laid, the batten should also be in the same plane. To do this, you can use pieces of plywood or wooden pads, pre-treated with antifungal composition.

In the case when the plastic crate is selected, it is necessary to observe perpendicularity with respect to the plastic sheets themselves more carefully, otherwise the fastener mechanism will not work.

Material selection

Plastic panels are made of a polymer called polyvinyl chloride. Being in a semi-liquid state, this material is laid out in a prepared form, and then a picture is placed on it. Most often, the image is printed on film, which is glued to the panel and laminated. Sometimes the illustration has a certain texture, but you have to pay more for the unusual design and decorative elements. Another possibility to fix the image on the panel is to paint it directly on the plastic and fix it with a double layer of varnish.This technology, as well as the resulting product, is much cheaper, but the quality of the picture and the duration of its existence suffer.

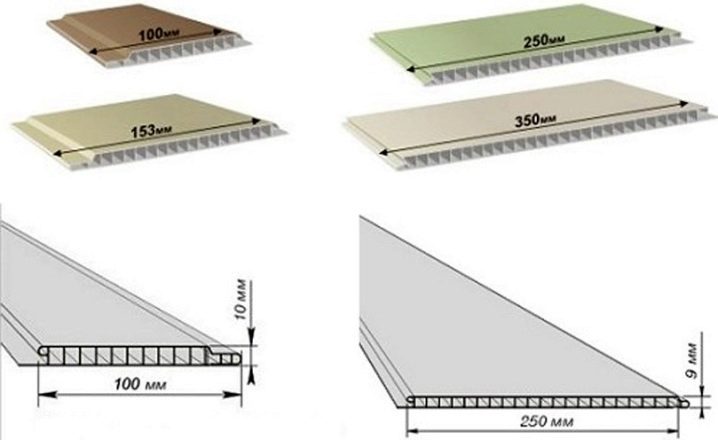

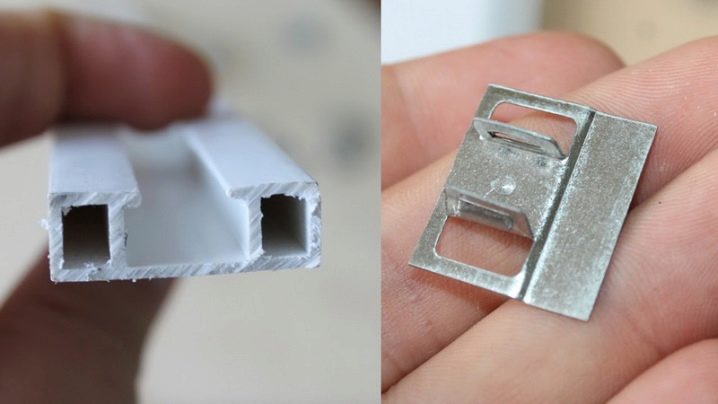

Plastic panels are most often chosen either on the wall or on the ceiling. The thickness of the ceiling reaches 5 millimeters, and the wall varies from 8 to 10 millimeters. Approximately the partitions connecting the two layers of plastic are also different - they are slightly thicker at the wall panels. To determine for repair of which surface one or another sample will fit, simply look at the cut. Plastic panels have smooth surfaces, so if you do the joining correctly, the seams will hardly be noticeable.

In addition, plastic panels are good because they can be used in the so-called cramped conditions. They are suitable for processing niches, door boxes, slopes and other places of the apartment, in which it is not very convenient to work with standard materials. For example, using a PVC panel, you can sheathe a window.

The material is easily combined with holes for ventilation, sockets, switches and other "outstanding" elements of the wall. The latter are not striking and harmoniously combined with the panels.PVC is also suitable for the decoration of "complex" rooms, for example, a concrete wall on an unheated balcony. It is worth mentioning that the sheets can be fixed both on concrete, and to drywall, and on wood, and on other bases.

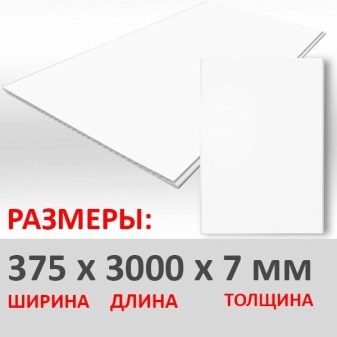

There are several standard sizes of wall plastic panels. The width of the finish is either 25 or 37 centimeters, and the length is 2700 and 3000 centimeters, respectively. These numbers are most common, but you can always order sheets with non-standard parameters. The range of prices is determined by the country and the manufacturer, the presence and difficulties with the design, wall thickness, print specificity and other parameters.

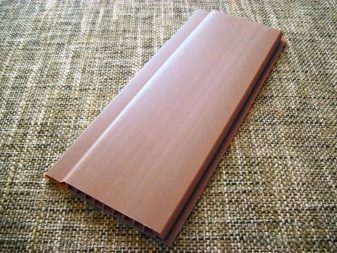

There is a variety of plastic panels, called plastic clapboard. It allows you to create a relief on the walls, reminiscent of wooden wall paneling. This material has a panel thickness of 10 millimeters, a width of 10 centimeters, and shaped edges are available.

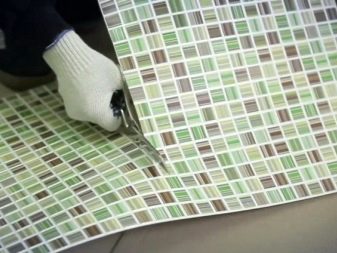

Relatively recently, this type of PVC panels appeared on the market, such as thin wall panels. Its thickness is only 3 millimeters, and the distinguishing feature is the absence of cells.The main advantage of this finishing material is that it cannot be pushed through, unlike standard models. Such panels are mounted only with glue. The material is quietly cut with scissors and after installation saves space in the room.

PVC plastic panels are good for almost everyone, but preferring them should be ready for some unpleasant moments. First, the material is quite flammable. Although in itself it is unlikely to catch fire, but when exposed to fire, it will still begin to emit toxic substances and support the process itself. Panels do not breathe at all - ventilation through the walls will be completely blocked. Therefore, PVC is not advised to install in the bedrooms and nurseries. In the voids formed by two layers of plastic, insects can settle. This problem is particularly acute for residents of areas with a warm climate. Finally, the panels require quality wall preparation for further installation.

What can I attach?

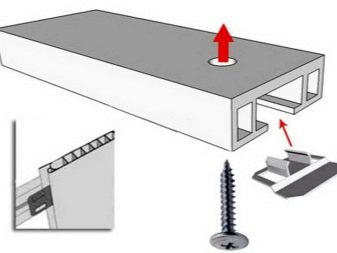

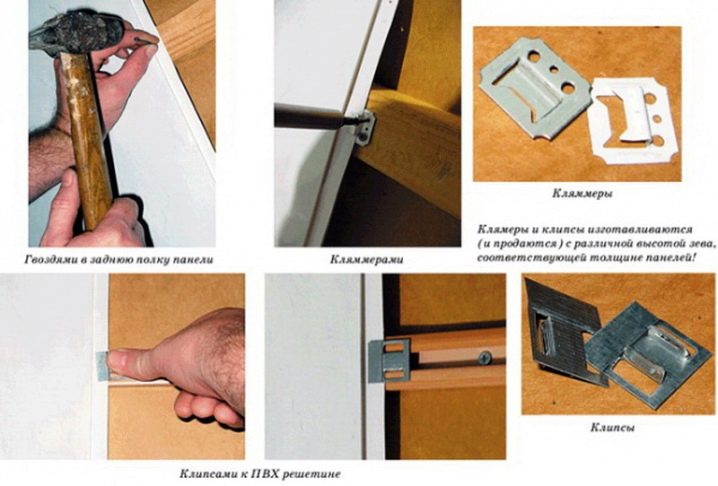

As for the question of how to fix the panels on the batten, it is better to avoid nails that can damage the material. The best method of fastening is carried out with the help of clips, but the brackets driven by a stapler and screws are also good.If the decision is made to glue the panel (which is possible only with perfect leveling and priming of the walls), then preference is given to liquid nails, Moment-Glue glue and other varieties. If the panels are installed in a bathroom, then only waterproof, non-toxic products should be used.

Required tools

Since the installation of polyvinyl chloride panels is easy to do with your own hands, you will not need any specific tools for this.

There are several common subjects to prepare:

- Drill with drills and a bit in wood (the first will be needed to install the dowels, and the second - to drill holes for switches, lamps, sockets and other parts).

- What will be the fastening of the sheets themselves. It can be glue (liquid nails or the universal “Moment-assembly” are considered optimal), a screwdriver or a screwdriver;

- Saw for sheet panels.

- Building level.

- Knife to adjust the parameters of the panels.

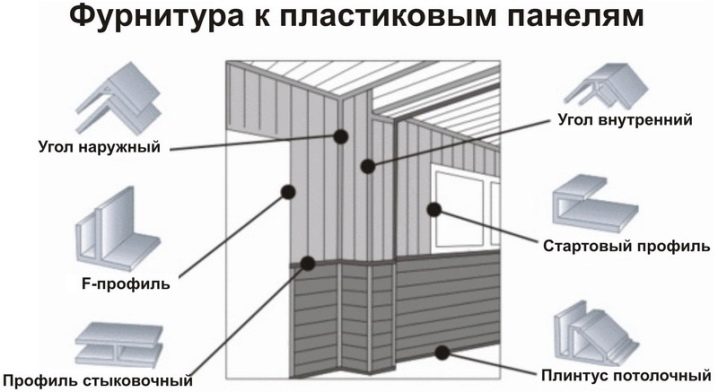

Of course, it is also worth buying a starting plate (to close the ends of the sheets or to arrange the joining points with door and window openings),corners to hide the joints in the inner corners of the room and other moldings, sealant for finishing welds, molding-connector to join the short sides of the panels in case of lack of length of one panel to cover the ceiling space, universal edging for the design of the perimeter and other details

The crate can be made of wood, metal or plastic. The wooden structure is assembled from pieces of size 40 by 20 millimeters. The material should be treated with an antiseptic solution and, if necessary, from mold. Fixing panels and wooden crates is carried out by using special screws, nails with large caps or staples.

Metal lathing is not always convenient for use, as it takes up a sufficient amount of space. Each wall will lose about 5 centimeters, which in the case of a small room can even be critical. However, if you still decide to use this type, then the fastening will be carried out using metal screws. Also it should be borne in mind that if the crate is located in a room with excessive moisture, the metal should be galvanized.

The plastic crate is designed exclusively for plastic panels. Its components are mounting strips and mounting clips that snap together. If necessary, this design is quickly dismantled. In addition, it takes up little space - the walls will lose only 1 centimeter.

Of the three types of sheathing, plastic is considered the most convenient, which can be used almost everywhere, followed by galvanized metal. The most careful thing is to be with a wooden crate and not to risk installing it in rooms with high humidity, for example, a bathroom. In any case, it must be treated with a protective solution.

Installation instructions

When the assembly of the batten is complete, you can proceed to the next task. Wall decoration with PVC panels begins with the processing of one of the corners. Above and below it is necessary to install auxiliary moldings and attach them to the crate with the help of fasteners that are combined with it. With this, it will be possible to create a kind of frame that will have to be filled with plastic sheets themselves. The first panel will need to dock along the length of the wall, so it is trimmed with a special saw.In the process you can not rely heavily on the material, and you need to cut only from the front. In order for the element to fit into the frame, you will need to measure its length, subtract 4 or 5 millimeters, and then cut it.

The finished panel is deprived of the protruding "tip", and then placed in the corner molding, tucking the edges. The bar is pushed to the stop, then the vertical is checked with the help of a level, after the panel is fixed on the crate. The mechanism is repeated several times up to the final panel on the wall. It will have to be shortened in width, and then docked simultaneously with the previous plate and with the corner molding. If it is impossible to do this carefully, you will have to wait a little with fixing the corner profile. First, you will need to put it on the last panel, dock with the previous one, and then fix it on the crate. If you do not want to work with the corner molding, then you can cut a strip of plastic with a knife and bend the panel as necessary.

It is also important not to forget that the material may change with temperature drops, therefore, during the “fitting” of the panels you should always leave a small gap.In addition, if the crate was made of wood and wide bars were used for it, then something could be placed in the space between the wall and the panels. For example, it can be heat insulating or sound insulating material.

When the wall after preparation turns out to be completely equalized, the batten can be abandoned. - it will not bring any benefit, but will “steal” the necessary square meters. In this situation, the plastic panels are glued to the silicone or mounting foam. Also in the store, you should carefully examine the composition of the glue you buy - whether it contains substances that destroy plastic elements. Starting profiles are mounted on dowels, sheets are covered with foam or silicone, the bar is inserted into profiles, pressed and fixed with fasteners. Correctly install everything you need quickly, because the flaws will be fixed only for a couple of minutes, and then the glue will harden.

Separately, it is worth mentioning the plastic paneling ceiling. Before installation, you need to figure out what distance is required between the ceiling and the panels - this value depends on the type of fixtures selected.If they are point-embedded, then the distance should be from 10 to 15 centimeters - so you can disguise the wiring and get to it without any problems if you need to fix something. Places where lamps will be placed are marked when the panels are still “on the ground”. The holes are drawn with a pencil, then cut out, and the bases of the lighting devices are installed. Further, all actions correspond to the same when facing walls. You can add that when working in rooms with high humidity, the distance between the panels and the ceiling itself can be filled with silicone sealant. It will contribute to complete waterproofing.

Installation always ends with the installation of decorative elements that give the structure a complete look. These include plinths with plugs and corners. At the last stage, all joints and seams are treated with sealant.

It can be concluded that the installation of wall panels with your own hands is quite possible without extra effort and physical effort. You only need to follow the instructions and use the tips of professionals. For example, during trimming and drilling of panels, you should always wear protective equipment to avoid damaging your eyes.When working with nails, you need to be extremely careful, otherwise there will be dents on the surface that cannot be fixed. It is recommended to clean PVC panels with a “mild” soap-based solution. Do not use hard sponges and potent tools, as solvent-based.

Polyvinyl chloride panels are recommended to be installed in living rooms, corridors, bathrooms and balconies, but for bedrooms, both adults and children, it is better to find more “breathing” materials. Alternatively, install panels only on a small section of the wall. Definitely not recommended to purchase this material for the kitchen. Fat, dirt and other substances will permanently settle on the surfaces, which will become a favorable environment for the appearance of bacteria. It is best to purchase plastic that does not create seams for rooms in which air conditioners are installed or forced ventilation is available.

Beautiful design ideas

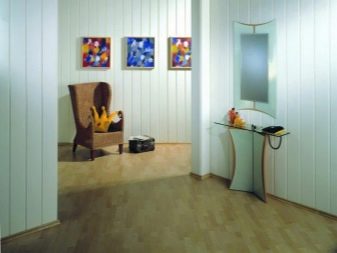

Plastic panels perfectly fit into the design of any room of the house, allowing you to create a harmonious and attractive interior.

The decoration of the walls and the ceiling of the bathroom with a wood imitation coating will add to the room a cozy and natural atmosphere.Complement the interior items made of stone and natural wood as a decor, as well as a wooden cabinet that houses the sink.

Marbled panels give the room a feeling of lightness and airiness. They are ideally combined with glass surfaces and require natural lighting.

The design of the hallway in a classic style requires panels "under the dark wood." This choice is simple and calm and does not require a large number of interior accessories. You can limit yourself to spotlights, a pair of table lamps and an elegant chest of drawers.

In the case when the room has high ceilings, the design of the corridor is proposed to be done by combining wallpaper and wall panels. Above will be placed the wallpaper of a light shade, and below - panels in harmony with them. The junction will need to be decorated with molding.

Lovers of pretentiousness, pomp and original designs will love the combination of panels with frescoes. As an option, two or three walls are sheathed with panels, and on the fourth there is a fresco that fits into the overall design of the room. In this case, you must be extremely careful with an excess of other accessories and furniture.

The use of white or neutral panels on the loggia will allow to improve the space and make it a “clean sheet” for the abundance of various colors and bright accessories.

The use of light panels on the walls and the light floor in line with them in the dining room requires contrasting, eye-catching pieces of furniture and good lighting.

Plastic panels can be used not only in residential premises, but also, for example, in a bath. The decoration of the rest room with sheets of light shades will allow to create a relaxing atmosphere, necessary after the adoption of water procedures.

Instructions for installation of PVC panels, see the following video.