Rules for wall decoration with MDF panels

Interior decoration is a task that is relevant for residential buildings as well as for public buildings. Among the presented range of building materials, various panels made of synthetic and natural raw materials are very popular. The latter group of products includes MDF-panels, whose variety of types allows you to choose the material for cladding rooms of any type.

Special features

Natural materials have always been at the peak of popularity, but, unfortunately, their volume is very limited. In this case, the correct and effective solution was the use of various waste products from natural products, which allows to reduce losses, as well as to obtain attractive and high-quality raw materials.

It was in this way that materials such as chipboard and fiberboard, and subsequently fibreboard called MDF, appeared on the shelves of construction stores.

Such products are widely used in the course of wall finishing in rooms.they prefer to be used in apartments, for covering bedrooms, kitchens and bathrooms, for decorating office premises, etc. This trend is due to the environmental safety of raw materials, reasonable cost, and ease of installation, due to which it is possible to mount these products at home do it yourself

The main components that make up the MDF panels are wood chips and other waste from this raw material. Special substances are introduced into such a composition and compressed.

The material manufacturing technology includes the following processes:

- The threshing device chops wood into elements of a given size.

- The resulting fragments are washed and sieved. As a result, larger chips and various debris are sifted out.

- After that, the resulting composition is treated with steam.

- An epoxy resin is introduced into the finished and purified raw materials and the mass is carried out under a press under high pressure.

- The resulting sheet material is cut into products of specified sizes.

- To give a smooth surface, the panels undergo a process of grinding and processing decorative compositions. Works on making products of external attractiveness consist in covering the material base with film, lamination or painting. The first option allows the panels to acquire similarity with wood or stone.

In addition, the decorative coating provides products with protection from pollution and moisture, which greatly expands the range of application products.

The following features should be attributed to the positive features of MDF panels:

- Environmentally friendly material - during the manufacture of products does not use phenol, which indicates the safety of the resulting raw materials.

- Sheath walls or ceilings can be without the involvement of hired workers.

- Cutting material is quite simple; with this task, there is almost no rubbish left.

- Today, a large range of similar products is on sale, among which there are panels having different colors and textures. Due to this diversity with the help of products it is possible to implement almost any design solutions, not only for small intermediate rooms, such as a hallway, corridor or toilet, but also to decorate the main living rooms - a hall or a living room.

And the cabinets decorated with MDF panels will highlight the good taste and status of the owner.

- Insulating and sound-proofing qualities are inherent in the material, due to which the level of comfort in the room increases.

- Products do not need any specific care, any contamination can be easily removed with a damp cloth.

- Since the main raw material used for the production of products has a low cost, the material itself is distinguished by an acceptable price.

- Sheathing of the surface can be done in several ways, so that in some cases there is no urgent need for leveling the base.

Fasteners on the frame will hide all the defects on the walls.

In addition to the advantages, some negative qualities are inherent in the products:

- the presence of additional coating on the products does not provide 100% resistance of the material to moisture;

- It should be borne in mind that the design will take a certain area of the room when installed on the batten;

- despite its environmental safety, products are classified as fire-hazardous building materials.

Kinds

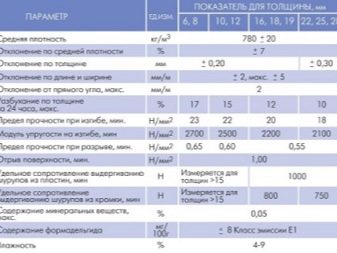

Taking into account the specifics of the production technology at each stage, MDF panels have the following characteristics common to all products:

- material strength varies from 600 to 1200 kg / m3;

- the average tensile strength of the product is 0.55 MPa;

- the permissible moisture level of the sheet should not exceed 10%;

- as a percentage, the level of various additives in raw materials is 10%;

- product thickness varies in the range of 6-40 mm.

Based on the production method, there are several main types of MDF panels:

- Moisture resistant products. The material is notable for its high strength and high cost. Such products are not deformed even with prolonged contact with water, they are well tolerated by mechanical stress and stress. The panels are recommended for use in rooms with high humidity, and in some cases, products are used for exterior decoration of buildings.

- Solid pressed products. The material is produced by hot pressing the panel components. Finished products have a smooth base, the level of strength of the panels is average in comparison with other types. Based on the proposed value of the manufacturers of the product can be attributed to the economy-class products.

- Laminated products.The production process is similar to the method described above. Among the individual features worth noting the ability of the material to repel water, abrasion resistance, as well as resistance to contact with chemicals. Due to its features and the strength of the product, it can be installed not only indoors, but also outside, but they are not suitable for constant contact with moisture.

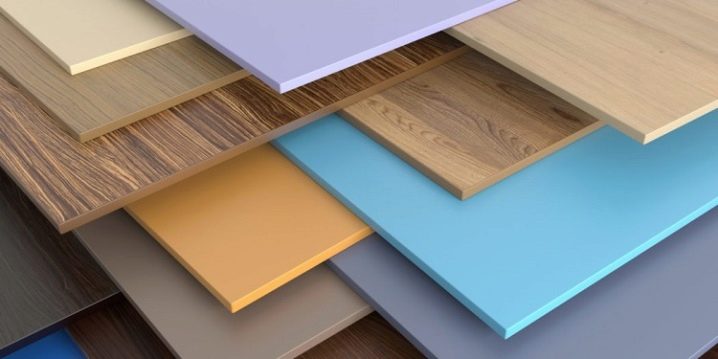

Taking into account the variety of exterior design of the rails, products can be classified as follows:

- Veneered panels. They are similar in texture and color to natural wood. To achieve this effect, the outer side is covered with a veneer layer of about 3 mm.

- Glossy. Have a laminating film layer. Due to its presence, the material acquires a brilliant appearance and resistance to moisture.

- Painted panels. For works, a special composition is used, which sets the necessary shade and hides the possible unevenness of the base.

Painted products can be both matte and glossy.

Given the differences in the density of products, manufacturers distinguish the following types of material:

- HDF - where the value exceeds 800 kg / m3;

- LDF - density ranges from 200 kg / m3 and higher.

The front surface of the panels can be milled or flat.

Focusing on covering possibilities, the material is divided into the following types:

- lath;

- tiled;

- sheet.

Scope of application

MDF panels have found their application in several industries at once. These include the manufacture of furniture, the construction industry, with the help of products you can mount partitions, arches, etc.

The following types of work can be distinguished where this product is in demand:

- manufacture door panels;

- the device of the roof lathing;

- manufacture of window sills;

- with the help of panels, protective shields for ventilation and heating devices are performed;

- products used for suspended ceilings and flooring;

- in the course of work on finishing the walls.

Preparatory work

To determine the amount of material required for the design of the grounds, you should take certain measurements - measure the width of the walls. Since the panels are available in different sizes, having decided on a specific type of material, it is necessary to divide the width of the wall by the same size of one product.

However, even properly organized work can be associated with various damage to the cladding products, so it is best to buy a little more material.

The preparatory process preceding the installation of MDF panels on the frame includes the following work package:

- In order to fix the product on the frame of wooden or metal type, the alignment of the surfaces is not necessary. In this case, it will be enough to clean the walls from dust and dirt. But serious defects need to be sealed.

- All the wiring that is available in the room is hidden in the corrugated pipe.

- If you plan to lay the material in a rather damp room, the walls should be pre-treated with an antiseptic primer.

The preparatory work, which precedes the installation of products on glue, boils down to the mandatory cleaning of the base, after which the walls need to be primed.

Rack type panels are cut according to the height of the walls, the corners are cut off, the edge is processed by sandpaper.

If you plan to glue square products, their size is adjusted after fitting.

How to fix?

The choice in favor of one or another method of installation of such products is based on the condition of the walls, as well as the specifics of the room and the conditions in which the material will be used in the future.

Frame mounting option is to install the lamellae on a specially equipped crate.

There are a number of recommendations regarding when to choose this way of working with MDF panels:

- in the presence of serious defects on the wall that are not possible to fix;

- when there is a question about the need to provide sound insulation and heat insulation;

- need to hide under the finish of various communications, such as wiring.

The frame can be made of wooden beams or galvanized profile. Each option has positive and negative features. Wooden construction does not need a large number of fasteners, it can be attached with screws, in addition, the raw material has similar characteristics in terms of moisture absorption, as the finishing material itself.

The crate needs additional treatment with antiseptics, as it is susceptible to moisture.

The metal construction is distinguished by a long operational life and moisture resistance. In addition, the metal frame ensures a more reliable and rigid mount, which is important in wet areas where the panels can be deformed and lengthened.

But the construction of crates, which will be many times more durable than the finish itself, is impractical.

Fastening of products can be carried out both horizontally and vertically.In addition, in order to create a specific pattern, some specialists carry out installation of products on a diagonal. Regardless of the chosen direction of installation, the frame and panel rails should be perpendicular to each other.

Vertical installation is considered to be the most common, since during such work there remains a minimum amount of waste after cutting products.

After the construction of the batten, you can begin to install the panels.

The following lining features are distinguished:

- The panels can be glued - in this embodiment, the composition is processed products in those places where they will be fixed with the frame. This method is relevant for products with a small plate thickness.

- Mechanical fastening with the help of hardware - this option will be acceptable for rooms with a stable temperature and normal air humidity.

- Fixing elements with clamps - the essence of the installation consists in putting the clip on the edge of the rail and connecting it to the frame with nails. This method is most in demand.

Installation is performed in the following sequence:

- The panels are adjusted in length, the edges of the products are sanded.

- It is best to install in the direction of the window opening, if there is one.

- The first plank is set in such a position that its edge with the ridge is directed into the corner. Next, the panels are fastened to the frame guides, a clamp is put on the edge.

- The following panels are fixed with a ridge into the groove to the previous element. The corners and the top edge are decorated with a universal corner.

Frameless method is chosen only in the case when the bases in the room have a perfectly flat surface.

Installation involves the following steps:

- work must begin at the corner of the room, moving in the direction of the window;

- before fastening on a concrete or any other surface on it, it is necessary to make a marking corresponding to the dimensions of the facing material;

- for high-quality sizing, the adhesive composition is applied on the reverse side of the product in a zigzag, after which the element is pressed against the wall and immediately removed;

- after a few minutes, the product is finally pressed to the surface;

- installation can be performed both end-to-end and overlapped;

- corners and edges are embedded with baseboards or corners.

Tips

In some cases, choosing MDF-panel as a finishing material, it is necessary to carry out work on additional base insulation. Such work can be carried out with the help of polyfoam and polyurethane foam or using silicone compounds.

In addition to thermal insulation, the presence of special materials inside will provide protection against the formation of condensate in the voids between the base and the lining and reduce the risk of the appearance of insect pests in the material.

In the summer period, with such a finish, the heat supply inside the building will decrease, and in the winter, on the contrary, its outflow will decrease.

Choosing a frameless option of mounting panels, you should carefully select the adhesive compositions for installation work.

Products must meet the following requirements:

- Differ plasticitybecause the products are subject to thermal expansion during operation.

- Glue should have a dense structure that will allow you to adjust the level of its application. This feature will allow fixing the lamella even on a highly curved base.

Beautiful examples

For a bathroom, even if it is small, the home has a special role - to help a person relieve fatigue at the end of the day or be filled with vigor in the morning. Warm glossy shades of the panels in combination with mirrors and glass will help the inhabitants of the home to recharge themselves with a positive attitude from the surrounding atmosphere of comfort and warmth in the interior.

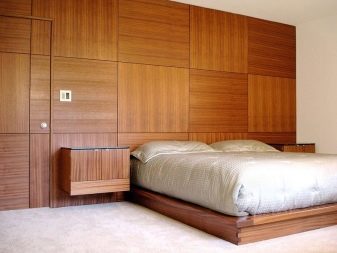

In some rooms there is a need for zoning space. In order not to pile up the area with different niches and partitions, the finishing of a certain area of the walls with decorative panels imitating a wooden base can serve as an excellent alternative. The contrast of shades will allow to highlight a specific zone and correctly place accents in the interior.

Balconies and loggias are part of the dwelling, often acting as a continuation of the room.Facing wall products of MDF, which imitate expensive finishing with natural materials, will help to harmoniously combine these two rooms. Contrasting alternation of light and dark slats will emphasize the geometry of the room, as well as add expressiveness to the interior.

You can learn how to install MDF panels on the wall from the video.