How to fix MDF panels?

The modern interior provides a beautiful and original finish, which in a special way emphasizes the style of housing. Therefore, recently, MDF wall panels have become very popular among designers. Unlike wooden boards, they are inexpensive, come in different colors and are easy to install, giving a refined look to the room.

Special features

MDF is a unique building material, produced in the form of panels from wood-fiber raw material of medium density. Since the plates are produced by the method of dry pressing of wooden chips under high temperature and pressure with the addition of carbamide resin, they are very durable and durable in operation.

Decorative finishing with such panels has many advantages.

- Easy installation. The material can be mounted in any direction: diagonally, across or along the surface of the wall.In addition, to install the panels do not need to carefully prepare the working base. The condition of the walls in no way affects the quality of the cladding.

- Aesthetic look. A huge range of color palette and textures allows you to use MDF for any style design. In addition, during installation, a small space remains between the plates and the base of the walls, which can be used to conceal insulation and wiring.

- Good thermal insulation. The material is characterized by excellent heat preservation, so after attaching MDF the room acquires additional warming.

- Easy care. To clean the panels of dust and dirt, just wipe them with a soft sponge dipped in warm water. If during operation damage has appeared, then there is no need to completely change the skin. For this, a panel with defects is removed and a new one is fixed in its place.

- Durability. Such a lining reliably last more than a dozen years.

Despite the presence of positive characteristics, MDF has some drawbacks.

- Low moisture resistance. Under the influence of moisture, the material is subject to deformation.Therefore, for the decoration of rooms with high humidity it is recommended to use special plates with a protective layer.

- Instability to mechanical damage and stress. Decorative panels need careful installation and maintenance.

- High risk of fire. Electrical wiring, which is laid under the finish, should be placed in the fire resistance of the box.

- Formation of hollow walls. Since MDF is fixed on the frame, there is an “emptiness” between the skin, so when you need to fix furniture on the walls, you have to use long nails or dowels.

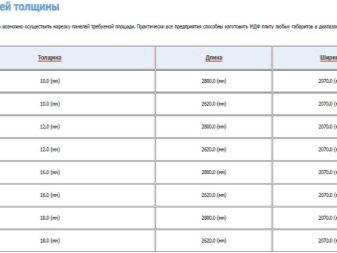

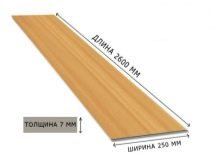

Before you buy facing plates, it is important to consider that they are made in different sizes depending on the model range of each brand.

As a rule, products with a thickness of 7 mm to 14 mm and dimensions of 2600 × 200 mm, 2600 × 153 mm, and 2600 × 325 mm are most commonly found on the market. Wall blocks are usually fixed on glue or a sheathing made of wooden bars and metal profiles. In this case, the installation of plates on a wooden frame is made much easier, but before starting the installation, the wood should be covered with antiseptic solutions that protect it from the formation of mold and fungus.

Today MDF plates are widely used in various fields. They sheathe walls, door linens, window sills, ceilings, as well as from the material they make screens for heating and ventilation systems and arches. Such a finish looks gorgeous in a modern interior, as the panels imitate not only expensive wood, but also natural stone.

Calculation of the amount of material

Installation of MDF, like any other material, should be started with a preliminary calculation of the number of panels. To do this, first of all determine the area of the room: make all the necessary measurements, and multiply the perimeter by the height. It is also important to consider the presence of doors and windows in the room. Their quadrature is calculated similarly, multiplying the height by the width, the result obtained is subtracted from the total area of the room.

Then, knowing all the numbers, you can go shopping for wall panels. Since the products are sold in different sizes, you will have to additionally calculate how many square meters in each slab. Manufacturers usually write this in packs. If, for example, a panel is acquired with a width of 900 mm and a length of 2600 mm, then it is sufficient to multiply 2600 mm by 900 mm. The result is that in one plate 2.34 m2.Then the area of the room, which is planned to be trimmed, you just need to divide by 2.34 m2, and you get the right amount of panels.

Preparation of tools

An important point before the beginning of MDF plating is considered and the preparation of the tool. Since the installation of wall panels is not particularly difficult, it is quite realistic to do it yourself, without the help of experts.

To perform work quickly and efficiently, it is necessary to have on hand a basic tool kit.

- Roulette. It will be best to use a 5-meter tape measure.

- Level. It can be either purchased in a store or made from jute, to the end of which a nut is tied.

- Drill with a full set of nozzles. It will perfectly replace the screwdriver and simplify the task of fixing the plates.

- Metal square. For installation, one that has different legs and is usually used by fitters. With the help of the square will be measured panel for cutting slopes.

- Hacksaw or jigsaw. It is recommended to stock up at the same time and the one and the other. In this case, the hacksaw should be chosen with small teeth that have transverse and longitudinal gash.

- Bulgarian.It is needed for cutting metal profiles, if the frame is planned to be assembled from metal.

In addition to the above, you will also need the usual tools that everyone has in the house: a screwdriver, knife, hammer, drill bits and a marker.

Mounting methods

Before sheathing MDF walls, it is necessary to determine how to fasten them. You can install decorative panels with glue or on the batten. Each of these methods is characterized by its installation technology.

Before choosing, you should evaluate the state of the surface, taking into account some nuances.

- The plates are made of wood fibers, so the material must be protected from contact with bases damaged by mold. Installation on the walls in rooms with high humidity is not recommended. In addition, the panel is required to mount on a flat base.

- In that case, if the walls are well cleaned from the old finish, dry, then they can be installed on MDF on glue or liquid nails without assembling the battens. This will simplify fasteners, but will exclude the possibility of replacing individual plates when they are mechanically damaged.

The installation of wall blocks on the frame is as follows: guides are fixed to the surface, which serve as the basis for installation, then MDF is fixed to the metal profile or bar.

This technique is characterized by many advantages.

- The batten hides the base defects, so the walls do not need to be leveled and leveled. This, in turn, significantly saves time and finances.

- Formed "emptiness" between the skin will serve as an ideal place for laying important communication systems and laying the insulation layer. In addition, additional sound insulation is created, which is especially important for apartments in which inter-wall partitions have poor sound absorption.

- The ability to quickly repair the finish if the individual panels were damaged.

As for the disadvantages of such a plating, it significantly reduces the area of the room, and if you need to hang furniture on the walls or decorative elements, then it is worth considering that the design will not withstand such loads.

In contrast to the previous method, glueing does not have significant drawbacks. MDF plates are attached directly to the wall, glue serves as a connecting element in this case. To fix the panels with each other additionally, clamps are also used. Thanks to this finishing option, the area of the room is not reduced, installation is carried out quickly, without damaging the material with screws or nails.But if during operation the facing surface was damaged, then it would be necessary to restore not one fragment of the finish, but the entire wall.

Determining the choice of a particular method, it is worth considering not only the features of the room, but also calculate the cost of plating. For example, in some cases it is much more economical to puttying walls, and not to build a frame. For large rooms, of course, it is best to install the crate, as ideally align their walls will be problematic.

Performance of work

MDF panels due to their performance and aesthetic appearance are widely used in the finishing work. Wall panels can not only trim the ceilings of the corridor, a passer-by, but also originally sheathe a doorway or window slopes. Furniture accessories and corners of walls are also easily made from the material at home. Since the product is easy to install, all the work is quite realistic to do it yourself. Before you mount the MDF, you should prepare the surface for finishing, cleaning it from the old coating and eliminating all defects.

Regardless of whether it is planned to coat the concrete, wood or brick, the base must be primed, this will protect the finish in the future from the appearance of mold and mildew.

For additional thermal insulation of the slopes of the window, walls and doorway, it is recommended to lay insulation material, it will not only serve as a good insulation, but also cope with the task of steam and waterproofing.

To install the panels on the slopes, they can be fixed along or across, it all depends on the size of the slope. Originally looks such a finish, made from a combination of light and dark pieces of slabs. Installation of panels on the walls and ceiling is carried out both on glue and on a pre-assembled frame. To do this, first mounted the start profile, and then the guides, the length of which you need to properly dock the decorative parts. To make a corner beautifully, before installation, you should cut the material, rounding its edges.

Cutting or cutting panels is recommended using special tools for working with wood. An electric jigsaw is considered the best option for this, but if it is not at hand, then a saw with fine teeth will do. Having decided on the direction of the MDF paneling, the panels measure out and cut to the required length. At the same time, it is necessary to cut a thorn along the entire length of the first slab; if this is not done, difficulties will arise when installing the corners.

Crate

Choosing the method of fastening MDF to the crate, you will first have to make a strong frame from metal profiles or wooden bars. It should be noted that the wooden structure requires pre-impregnation with antiseptic solutions that protect it from rotting and mold. If laying of thermal insulation is planned, then the thickness of the bars is chosen according to the thickness of the insulation material. It is not recommended to use a wooden frame for covering brick walls and rooms with high humidity.

In order not to deform the wooden bars during installation, you should choose a well-dried tree. They fix the structure perpendicular to the installation direction of the panels, leaving a small margin of 5 cm from the floor and 3 cm from the ceiling. First of all, they fix vertical elements that are placed along the edges of the grooves, in the corners and near the openings. The slats must be 700 mm apart. For fasteners designs usually use screws or nails with a diameter of 4 to 6 mm.

UD racks and horizontal CD profiles are used to assemble the metal structure. The pitch of the batten is similarly 600-700 mm.

CD profile is inserted into the rack and all attached to the wall with screws. Metal profiles can be cut with a special circular saw. If the ceiling panels are trimmed, then the frame should be assembled only from horizontal elements, using additionally fasteners.

Paneling

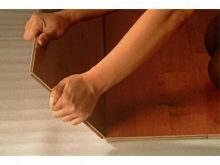

After the frame construction is ready, proceed to the paneling. MDF plates are fixed among themselves with the help of a tongue-and-groove lock consisting of a hollow and a ridge. The parts are fastened to the wooden crate with small nails, they are hammered with a hammer obliquely. To install the material on the metal profile, use the clamps, they are placed in the groove of the plate and secured with self-tapping screws.

When the vertical installation of MDF begin to fix from the corner, smoothly redirecting to the left. The first plate is fixed to the timber with nails, and from the side of the groove fixation is carried out with Klyimer. Then the next plate is placed in the groove of the first one. The last panel should be cut along the length, leaving a small margin of 5 mm, and its crest cut off by half. It must be inserted into the groove of the previous panel and secure the free edge.

Apply pieces of wall plates to a covering of slopes.To beautifully close the casing, use special angles. They are put on liquid nails or glue, decorating the edges near doors and windows. In addition, MDF is excellent for finishing the ceiling surface, in this case, the panels are installed in a direction perpendicular to the base of the walls.

Recommendations

The construction market is represented by a huge range of MDF panels. For finishing inside the house, material with a painted and laminated surface is usually used. They can be sheathed as the surface of the walls, ceiling, and doorways or arch, which is pre-installed on a plasterboard frame. Depending on the scope of the wall panels, their installation is carried out in different ways.

Carrying out the mounting MDF do it yourself, it is worth considering a few nuances.

- Panels with a painted surface are not resistant to mechanical shocks, because of this, their installation requires special attention. It is necessary to fasten the material carefully, avoiding the fall of heavy objects.

- Products with laminated film are afraid of high temperature, so they should not be placed near the gas stove and appliances, which are a heat source.

- Veneered MDF is not recommended to be installed in places where it is possible for oil and fat to get on their surface.

- It is best to cut the panels with a hacksaw with small teeth, while doing so it should be done along, and when using an electric jigsaw - across.

- When mounting, it is necessary to avoid liquid on the surface of the plates, otherwise they may be subject to deformation.

- Choosing a fastening system, it is desirable to give preference not to self-tapping screws, but to clamps. They will provide high strength finish.

- In the case when the MDF is mounted in a frameless manner, the panel must be pressed to the wall, then torn off, wait 10 minutes and complete the installation.

- For sheathing curved structures, you need to purchase "curved" MDF.

Examples of facing in the interior

- In modern interiors, MDF decorative panels are used not only for interior walls, but also for cladding the surfaces of the toilet, hallway, loggia and attic. Carrying out the next repair, it is possible to finish with such material both living rooms of the apartment, and a balcony.

- Especially beautiful looks trim in living rooms and bedrooms. For this, the walls are either fully sheathed from floor to ceiling, or separate compositions are made, originally separating part of the room.An unusual decision will also be the manufacture of wall panels, which will give the design a bright touch.

- In the master bedroom MDF can be placed on the wall behind the bed. A common design idea is the installation of panels on the walls in the living room under the TV. Material for wood with veneered surface will serve as an excellent background for TV.

- No less popular is the finish in the kitchen, where shears a kitchen apron. In this case, the texture and color of products must be selected in such a way that they are combined with the equipment and the facade of kitchen furniture.

For how to install the MDF wall panels, see the video below.