MDF panels for walls: types and colors

The choice of materials for interior decoration is not limited to wallpaper or paint. You can use MDF panels for walls, since their types and colors allow you to create interiors in various styles. In addition to the attractive design, the material has functional advantages.

What it is?

The abbreviation MDF is an abbreviation for the English name of the material, which literally stands for chipboard. That is, it is an analogue of chipboard, only higher quality in its technical characteristics. The raw materials for its production are waste wood industry - sawdust, small chips. All these are natural fibers. To connect them,paraffin or lignin is used - harmless binders, therefore MDF can be used in any residential premises, plates are safe for humans and animals, they are considered to be an environmentally friendly material.

Despite the fact that the technology of manufacturing the plates is the same, there are different types of this material - moisture resistant, which are suitable for rooms with high humidity, laminated with a beautiful coating, so you can choose sheets for any need.

Specifications

The properties of the panels may differ slightly depending on their variety, but the characteristics must correspond to certain indicators.

This is governed by the regulatory documents that manufacturers are guided by.

- In the composition of not less than 90% occupy sawdust, the rest falls on binding materials and components that prevent rotting.

- The strength of the plate is in the range of 17-23 MPa.

- Allowed up to 10% moisture, but not less than 3%.

- Density is an important indicator that determines the strength of the panel. Usually ranges from 600 to 850 kg per cubic meter. You can check how the declared figures correspond to realityif it is possible to weigh the slab, and then the resulting mass needs to be divided by the volume - this is the product of the three dimensions of the panel.

- Moisture resistance may be different. There are ordinary plates and those that have increased resistance to moisture by adding special components in the manufacture.

- To impart fire resistance use additives - flame retardants.

- At the production stage, the raw materials are processed so that the finished products become resistant to biological effects - fungi and mold.

- In addition, MDF may differ in texture, product design, colors and other consumer characteristics. When choosing panels, first of all you need to pay attention to their density, since the strength and durability of products depends on it.

The problem with this material is its fire hazard, since wood is based on it. Despite the fact that many manufacturers add special components to make the plates safe, they still should not be placed near the source of open fire.

Also, when buying, it is better to check the documentation, which confirms that there are components in the products that prevent fire and the spread of fire.

Kinds

Wall panels based on MDF may differ in production technology. Solid-pressed are obtained from a homogeneous mass, which is processed under a press with high pressure and under high temperature conditions. As a result, the finished product looks like a smooth slab. This method allows you to create panels that provide good thermal insulation and sound insulation.

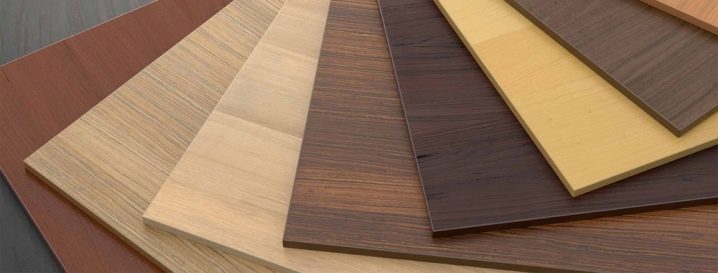

Laminated wall panels are made in a similar way., but additionally covered with a thin film of polymeric materials, which gives the product strength, resistance to mechanical stress and moisture. These plates come in a variety of colors, so it is easy to choose an option for any room design.

Special moisture-resistant panels for interior decoration are also made by hot pressing, they are washable and can be used in bathrooms or kitchens, while at the time of production the temperature effect lasts longer, and wood dust has a more dense structure.

Products may vary the design of the front side. Veneered imitate the texture of natural wood, and so accurately that at first glance it is not always possible to distinguish decorative panels from solid-wood slabs.Wall panels will be appropriate in a classic interior, as well as carved products with decor. Glossy coated with a polymer film, which gives the surface a characteristic shine. Can have the most different coloring. Painted are made using dye that is applied at the last stage of production and gives the tiles the desired shade, and also smoothes unevenness.

Forms of release may be different:

- Tile products are usually square in shape, fixed with glue, can be combined with other materials in the interior;

- Rack-like look like slats of different lengths and thicknesses, fasten to the crate and help to visually expand a small space;

- Sheet used when you need to quickly perform finishing work in a large room.

Dimensions

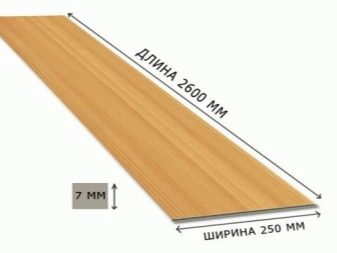

Depending on the manufacturer, the dimensions of the products may vary. Available in large and small plates, wide panels and narrow slats.

However, there are a number of standard indicators:

- length - 2.6 meters, but the parameters may differ both upwards and downwards;

- the width for a conventional slab is within 90 cm, but some products can be 1.2 meters, and for rails these figures are about 15 cm;

- thickness ranges from 3 mm to 3 cm, and veneered plates can be up to 6 cm.

Thickness indicators are directly related to the strength of the products. Too thin can break or bend, and the thick require special fastening. The best option is about 10 mm. Materials with a thickness of more than 1.2 cm can be used as additional thermal insulation, since wood retains heat well. The coating also provides sound insulation in the room.

Color spectrum

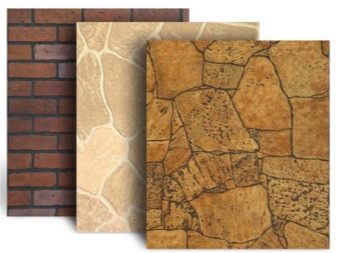

Popular under the tree panel, which imitate oak, wenge or other expensive breeds. Quality products look like solid-state slabs, but they are cheaper and weigh less. They can be used in classical and modern directions, embodying various design ideas. The panel can imitate any pattern and although wood texture is the most popular, there are also colors under stone or leather.

On sale you can find colored MDF. They are monochromatic, in the palette are presented any colors from the spectrum, as well as white and black plates. The surface can be matte or glossy.There are options with a pattern - a pattern or ornament, as well as a full-fledged photo printing with the transfer of some complex images.

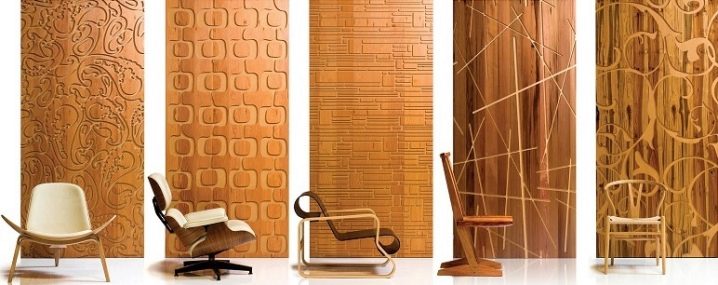

Design

Decorative plates can be quite interesting. These are not only plain coatings - glossy or matte, but also various products with drawings that can be combined with each other. Especially beautiful in the interior are openwork plates with a volume carved pattern. They can be attached to the wall or used as a light partition that will make the decor more elegant.

If the color of the panels has ceased to arrange or you want to update them in connection with the upcoming repair, then the products can be painted using lacquer or other similar materials. This will not only change the color, but also hide small roughness or scratches that could appear during the operation.

Application

Due to its advantages, the panels are widespread. Wall cladding is the most common use. With these plates you can create almost any decor in a classic or modern style, come up with an original decor.Materials are easy to clean, and moisture-proof can be washed, so the plates are suitable for decoration in the hallway or hallway.

In the kitchen, they can also be used, and not only for cladding walls. From the stove can be made tabletop for the dining table. If the kitchen furniture is intended for cooking, then it is better to choose a stronger material. MDF is used for the manufacture of furniture facades. During production, the plates can be given any shape, even curved. Apron from MDF is an economical solution, it is quickly assembled, looks beautiful, and if necessary, some part can be quickly replaced. But traditional materials, for example, ceramic tile, MDF is inferior in durability, resistance to temperature and moisture, strength.

Some types of material are suitable for use in the bathroom, at least, so the manufacturers assure. However, this issue has its own nuances. Under prolonged exposure to high humidity, the plate can change shape, fungi and mold often multiply behind the panels, and the products themselves can be damaged due to mechanical effects.Therefore, although they are conditionally suitable for a bathroom, it is better to use it in a room where the owners are not satisfied with long water procedures for several hours with steaming in hot water.

In the bedroom, you can use panels to trim the area at the head of the bed. It is not necessary to sheathe all the walls, but to single out one part is an interesting solution, especially if the bedroom combines several functions, for example, it has space for working space. The use of accents in the form of panels will help to delimit the room.

Suitable MDF and for the balcony. With the help of plates it is possible not only to sheathe the walls beautifully, but also to insulate them additionally, since the material is characterized by good thermal insulation. Sheathing can be used for walls and ceilings. In any other room, the ceiling can also be trimmed with MDF to create a flat surface or a design multi-level construction.

Regardless of which finishing option was chosen, you can do it yourself. Since working with MDF is not too difficult, it is not necessary to resort to the help of a master. The main thing is to prepare all the tools and purchase the material.It is better to purchase it with a bit of stock.

Cutting panels will require certain tools.

You can use one of the following options:

- hacksaw for wood - preferably with the largest teeth, from small material begins to actively crumble;

- jigsaw - with it you can make accurate and even cuts without spending a lot of time;

- Bulgarian is a noisy tool, using which waste remains in the form of sawdust, but in the absence of other options this one can also be used;

- A hacksaw is suitable when you need to cut with maximum precision, as it can create very neat cuts.

In order for the MDF coating to last longer, it is recommended to pre-prepare the surface. If there is a layer of plaster on the wall, then it should be removed - it can eventually accumulate moisture and deteriorate the condition of the plates, as well as contribute to the appearance of mold. After cleaning, there should remain a flat surface, which is treated with an antiseptic and ground.

Sheets of sheet format are mounted on a batten, which can be metal or wood.In the latter case, it is necessary to take care of the additional processing of the structure in order to protect it from moisture, fungi and mold.

During installation, one of the methods of joining the panels is used to ensure that they fit snugly together:

- the most common option is the thorn-groove connection;

- there may be a groove-groove fastening;

- profiles are used for joining, which fasten the plates together;

- mounting on glue is possible only on a flat surface and for light panels.

During installation on the batten, an additional layer of thermal insulation material can be installed, if necessary. In the case when under the panels will be wiring, it is worth using fire-resistant corrugation to avoid fire and fire in case of short circuit or other malfunctions.

Moisture-resistant panels have their own characteristics - nails cannot be used for their installation, since they violate the integrity of the material and the protective coating, after which the moisture can penetrate inside the slabs. To fix these plates, apply a special glue. At the same time between them remains a small distance, which is then coated with sealant.

How to paint?

In some cases it may be necessary to paint MDF.This is usually done in order to protect the panels from negative impacts, to update old enough products or to change the skin color if you want to change the interior. Since the work is carried out indoors, you need to pick up non-toxic tools. It is better to use special formulations designed specifically for working with MDF - they are safe.

Coloring gives several advantages at once:

- using such a coating, you can make the panels more resistant to temperature effects and use them as an apron in the kitchen or in other similar places;

- special additives: pearl, mother of pearl, metallic - this is an opportunity to add uniqueness to the finish;

- Painted products last longer, because the paint coat provides additional protection.

For painting it is better to use polyurethane compounds that do not contain volatile components, are safe, provide uniform coloring. Also worth buying a primer with the same base.

The work process requires advance preparation.

- First, the surface must be carefully polished - this will help to achieve better adhesion, that is, adhesion of paint to wood material.Grinding can be done with a special machine or sandpaper manually.

- After stripping, the surface should be degreased using an anti-silicone.

- If the panel has already been used for a long time and roughness, dents, scratches and other noticeable defects appeared on it, then they need to be puttied. You can use acrylic putty on wood and a rubber spatula to apply it.

- After that, you can use a primer, spreading the tool evenly over the entire surface. It takes at least 12 hours to dry, then you will need to rework the panel with an emery tool.

After all the preparatory work can proceed to painting. For this fit a brush, roller or special remote. The room should be warm enough, but not hot - about 20 degrees. Depending on the conditions, the drying of the paint can take from 5 hours to a day.

Reviews

Owners of decorative MDF panels, imitating wood texture, note that in the interior these products look presentable and expensive, they are often mistaken for slabs of solid wood. Those who have been used to design a single-color panel with a glossy finish, noticed that they practically do not fade in the sun.Moreover, all products of this type do not require complex maintenance and serve for a long time.

Conveniently, if necessary, part of the skin can be replaced if it is damaged or wants to change the situation.

Options in the interior

- You can add originality by placing the plates in an unusual way.. When finishing this wall, panels of two sizes were used - rectangular and square, but the chosen method of laying creates a very interesting effect that resembles a mosaic or a wicker panel. At the same time, the finished walls look beautiful and due to imitation of wood texture. The color of MDF is quite dark, so it is best to combine it with some light details to make the interior look harmonious. It is not necessary to lay in one layer. Why not go beyond, because you can come up with the original version and add volume. In this interior, on top of the styling, imitating the boards, more panels were laid out. With such a design, even a wall in restrained colors looks new, it doesn’t need any additional decor.

- You can make a variety using different colors. In this embodiment, a unifying direction has been chosen - all panels have a pattern of natural wood, but the shades are different.This effect is similar to a mosaic, but it does not seem to be too intrusive, as a discreet gamut of brown tones is observed, including molding, which is used to emphasize the decor. The material here is well combined with stone, which is decorated with a small wall on the side.

- Panels can occupy only part of the space.it is not necessary to finish the whole room with them. The combination of such products in the lower part with the wallpaper located above is a classic solution. If you like Victorian style and English classics, then you can choose this option and create a discreet but elegant interior using MDF.

- Paneled headboard design - an interesting idea for the decor. The walls at the same time can be monotonous and light, and MDF - a dark shade, with a pattern under a tree. Such an original accent will make the design unusual. If there is a need to delimit the space in the room, then this solution can be used for zoning.

- MDF is not only panels with wood imitation, but also monochromatic products with a matte or glossy surfacewhich can be made in any color.If you want to create a modern interior style, you can use bright red plates of different sizes, arranging them on the wall as a mosaic panel. It is better to make such a lining for one wall, which will be considered as an accent, and arrange the rest of the space in more restrained colors so that the situation does not seem overloaded and screaming.

- Panel apron - it is quite real. So that they last longer and are not afraid of the temperature difference, they are treated and varnished, after which you can make any design you like. In this interior a discreet black and white gamut is chosen in combination with a classic setting. MDF rack panels form an apron over the working surface and are used as cladding for walls in the room.

- In this living room, it creates the effect that the wall is cracked by the blow. The panels were specially given an irregular shape and arranged in a special order to create such an impression. Since MDF is easy to process, it is easy to do. Perhaps not everyone will like this solution, but this idea looks quite original.

- Panels can act not only as a wall covering, they are obtained from original partitions for zoning space. So that the surfaces do not merge, you can use plates with different patterns, but at the same time leave one color gamut to make the interior look uniform. The combination of two colors creates an original contrast. White battens look spectacular, and brown makes the atmosphere not so strict, adding comfort to it. At the same time, the original arrangement on the diagonal helps to visually expand the space, so this option is also suitable for small rooms. The drawing can be located only on one of the walls, while others can be white with the use of brown facades on the furniture. This combination of colors makes the overall look more interesting.

In the next video you will find the installation of MDF panels on the walls.