Standard sizes GVL-list

GVL - one of the most popular building materials, its abbreviation means gypsum fiber sheet.

To finish with it and incur the least material costs, it is necessary to accurately calculate everything, taking into account the individual characteristics of the project. Knowing the existing sizes of the GVL list will help you not to be mistaken in the calculations.

Special features

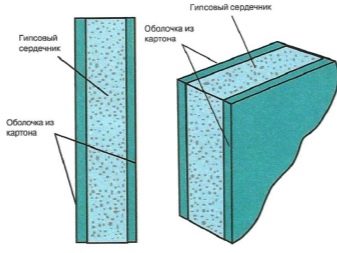

The basis for its production is gypsum, to which cellulose fibers obtained from waste paper are added, their percentage is 15–20% and they serve as a reinforcing substance. Externally, this sheet is very similar to drywall, there is only paper on the surface. But has a higher performance.

The service life of such plates is much longerand the properties of moisture-resistant sheets make it possible to install in rooms with high humidity.

This is quite popular lately building material. used for interior decoration inside and out.

It consists of two layers of cardboard paper used in construction, and the core, which consists of hardened gypsum-water mixture and some fillers, giving the mixture the necessary beneficial properties.

It was first invented in the United States in the 19th century by Augustine Sackett, the owner of a huge pulp mill. But over time, the new composition and size of drywall patented Clarence Utsman - an American engineer.

Now the usual width of the sheet is measured in the range from 60 to 120 cm. It is used in rooms with a dry and humid climate. Modern composition: 92% gypsum, 6% paperboard, 2% is water, starch and other organic matter.

Standard dimensions of canvases

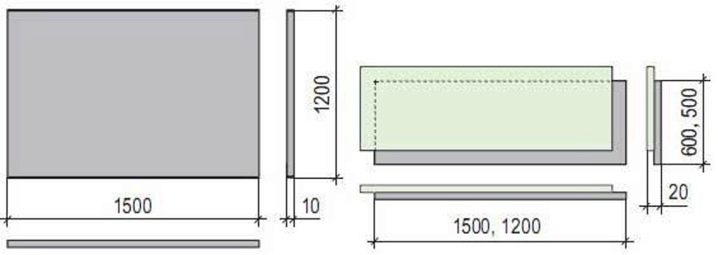

GVL - sheet material. State standards provide the sizes of cloths in centimeters:

- width – 50, 100, 120;

- length – 150, 200, 270, 300;

- thickness - 1, 1.25, 1.5, 1.8, 2, with increasing thickness, the strength of such a plate becomes greater.

The standard sheet for domestic work is the size of the canvas 150 x 120 x 1 cm.

In addition to standard sheets, many manufacturers produce highly specialized products.For example, the brand Knauf produces special sheets for the dry floor screed “KNAUF-superpol”, their size is 120 × 120 cm with a thickness of 2 cm. folding 5 cm wide are formed.

With increasing thickness, the flexing strength decreases. This must be borne in mind during transport and installation. These sheets create arched structures, as they are very durable when bending.

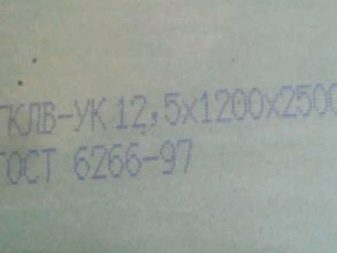

Manufacturers on the reverse side of the sheet produce marking in all three parameters (length, width, thickness). In the production process, cellulose fibers are added to the gypsum under pressure, and the mixture is pressed. The result is a dense reinforced canvas. If such a cloth is impregnated with special hydrophobic substances, a moisture-resistant sheet, GVLV, is obtained. Since the surface of such sheets is not covered with paper, the resistance to fire increases, as compared with GCR.

The standard thickness of gypsum fiber sheets is generally 10 or 12 mm. The frames can be 1200 x 3000 mm or 1200 x 600 x 12 mm.

Weight

Compared with drywall, gypsum-fiber sheets are much heavier. Therefore, their installation is mainly carried out using a metal or wooden frame. The adhesive method can also be used, but for sheets with small sizes.

And yet the material is quite light and will not create an additional load on the walls. therefore It is perfect for arranging partitions.

Custom offers

Non-standard sheets are usually smaller than standard ones. As a result, they are much easier and easier to work with. Such sheets are used most often in individual construction.

Moisture resistant gypsum fiber a sheet with a canvas size of 150 cm by 100 cm by 1 cm is perfect for covering the wall in a toilet, bathroom or small storage room. You can mount it using an adhesive mixture.

Before installation, it is imperative in this case that a preliminary surface treatment of the wall with special hydrophobic compounds is necessary.

Sheets that are thicker than specified in the standards are usually used as a backing for flooring. This makes it possible to level the floor without too much dirt. Sometimes on sale there are atypical materials with a length of 360 or 600 cm.

GVL sheets with dimensions of 150 x 120 cm, with a thickness of 1 and 1.25 cm can be mounted independently. These sizes are suitable for arranging walls, floors in private homes.

Sheets of larger dimensions should be assembled by qualified builders.Basically such plates trim industrial enterprises.

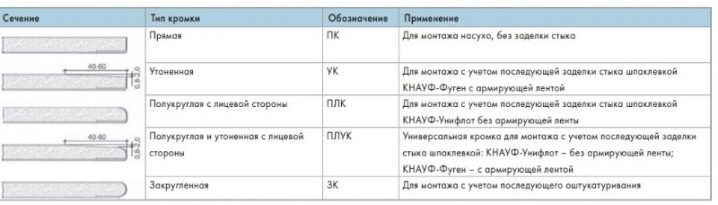

In addition, the sheets come with a straight edge without chamfers, then the marking is applied - “K” and with a falsetto edge - “FC”. Additionally, markings can be applied indicating the type of surface. "NSh" - not polished surface or "Sh" - polished.

When is use possible?

The material is used during construction work in rooms with normal and low humidity levels. You can even use it in the repair of attics, but only if there is sufficient air circulation. In the kitchen, in the bathrooms and other rooms with high humidity, moisture-proof building materials are used - GVLV.

The material is frost-resistant, it allows the finishing of unheated premises, for example, garages, sheds and other outbuildings. For wooden buildings the use of GVL provides fire protection.

Due to its ease of use, you can easily build a partition with your own hands, or lay a floor board. This will significantly reduce the cost of repairs.

Like any building material, this one also has its advantages and disadvantages.

Positive characteristics:

- Since the gypsum-fiber sheet contains only plaster and paper, this is an environmentally friendly material. When working with it, no toxic substances are released, there is no risk of respiratory diseases when sawing sheets. It does not contain synthetic resins and polymer inclusions, it can be safely used for interior decoration of residential premises.

- Resistant to temperature changes, so it can be used in unheated rooms.

- It has high noise insulation characteristics. Can hold back noise 30–45 dB.

- GVL tolerates moisture well. Therefore, it is used in the decoration of kitchens and bathrooms.

- High fire resistance makes it possible to sheathe wooden floors, beams, walls.

- It has a low thermal conductivity, is used for wall insulation.

- The high viscosity of the material allows nails to be driven into it and screws to be screwed in, while they will be securely fastened inside the sheet. This factor also influences the fact that GVL practically does not crack and is not painted. It can be easily cut to the required dimensions with the same tools as drywall and plywood sheets.

- Easy, so when installing, you can use inexpensive profiles and frames.

- The material is easy to process, a minimum of waste during installation.

- Thanks to the use of cellulose fiber, the sheet is more flexible than the gypsum board. Its bending strength ranges from 5 to 6 MPa, and this is significantly higher than that of drywall. Therefore, it is easier to make complex decorative structures from GVL - arches, curved surfaces.

- The gypsum-fiber sheet can withstand up to 20 freezing cycles without losing its characteristics, which allows it to be used for finishing periodically heated or unheated rooms.

Despite the huge number of advantages, the use of GVL has some disadvantages:

- big weight, one plate - about 18 kg;

- GVL price is higher than drywall;

- absorbs moisture well, this limits the use of the material or requires treatment with special water-repellent substances.

There is a wide range of products on the market. Usually the best manufacturer is the brand that first produced this product. At the moment, Knauf is considered the best in all of Europe.although the most expensive. On the market there are products of domestic producers, but the technical characteristics of the material may be slightly worse.

When buying any building materials it is better to make sure that a certificate is available.for goods and compliance with GOST. Make sure that there is a marking, it must indicate the size, type of edge, GOST.

Spheres of application

For walls

Gypsum-fiber sheets are used for walls with the purpose of leveling the surface, for sound insulation and thermal insulation.

You can mount this material in two ways: frameless and using a frame. Frameless method is used if the wall irregularities are not too large. Special plaster glue is applied and pressed to the wall. In this method, the sheets are better to take small parameters..

If the wall irregularities are large, up to 3-4 cm, the sheets are glued with special glue, applied around the perimeter and in the center, every 30 cm. Before installation, the material is entered into the room for 2-3 daysso that it adapts to temperature and humidity.

In the frame method GVL is fastened with the help of self-tapping screws with double-row thread to the frame made of durable galvanized profiles. Inside you can put the material for insulation and sound insulation. Profiles must be selected to withstand heavy weight.. Installation is carried out from the bottom up, starting from the corner of the room.

After installation, cut out the outlet and close up all the joints with putty.

For the floor

Mark up the floor level. Stacked vapor barrier. The use of GVL allows you to use the so-called heated floors. Expanded clay is poured onto the prepared surface and leveled. Sheets are coated with glue and fastened with screws. Joints putty.

On such a floor you can lay laminate flooring.

If it is thin linoleum, then it is recommended to fill the gypsum-fiber coating with a layer of leveling mixture.

Such wonderful material as gypsum-fiber sheet is widely used in construction and repair work. It is a reliable building material for interior decoration. It justifies its high cost, which is higher than the usual drywall sheets, a number of characteristic advantages.

Read more about GVL in the next video.