Porcelain stoneware drills: features of choice

Due to its excellent functional and aesthetic properties, porcelain stoneware has recently become increasingly popular. To achieve maximum productivity, you must use a professional tool.

One of the tools without which it is impossible to imagine working with a ceramic granite slab is a drill. Conventional drills in this case are not suitable, and there is a need to use a special tool. It is worth more to understand the features of such products.

Surface features

Everyone knows the following properties of porcelain: resistance to abrasion and mechanical damage, increased strength, water resistance, frost resistance, fire resistance, uniformity, resistance to sliding.The main difficulty in working with porcelain stoneware lies in the fact that it is generally quite fragile. In Italy, porcelain stoneware tiles are called "stone-porcelain stoneware."

To drill porcelain, it is necessary to understand the physical relationship between its hardness and brittleness. The drilling of porcelain stoneware tile becomes effective and accurate after all the physical and mechanical properties of this material are taken into account.

Professionals warn that with improper drilling there is a high probability of spalling, such a defect does not look very aesthetically pleasing.

What are the drills?

Today you can drill porcelain stoneware using the following tool types:

- diamond drills;

- diamond bits with electroplating;

- sintered annular drill bits.

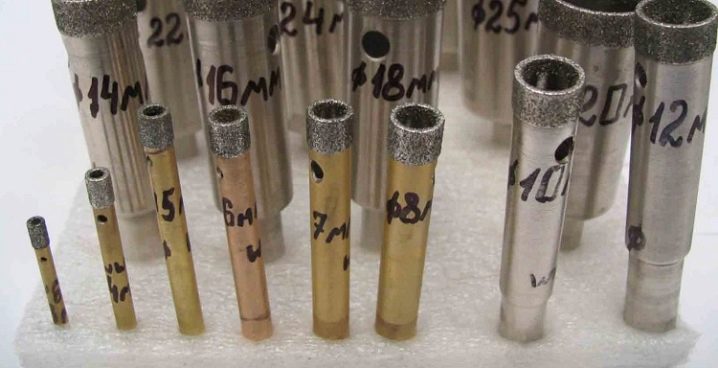

Diamond drills on porcelain are conventionally classified according to the types of bases.

Classification by production method, the introduction of the diamond group:

- Electroplating diamond chips on the edge of the cutter. Such drills are suitable for relatively soft stones. Most often cylindrical drills are made this way.

- Sintering the diamond fraction with an alloy of metals, soldered to the drilling area of the tool. According to this technological scheme, durable ring and tubular drills are produced.

- Vacuum diffusion method of applying a diamond layerused in the manufacture of conical products, feathers. It is ideal for working with superhard material. It is used when you need to drill a hole 6 mm, 8 mm or 10 mm.

By type of cutting edge:

- Cylindrical - cut porcelain solely on the exterior of the circle. The surface of contact with the material is quite large. Such products are used for the purpose of drilling holes of increased radius.

- Conical - visually very similar to ordinary drills for metal. They cut the slab across the horizontal drill. Designed for drilling small recesses.

- Feather. Drilling zone - in the form of a sealed pyramid-shaped plate. Such products are well suited for deep drilling.

To destination:

- Diamond crowns - these are cylindrical drills for drilling holes from 12 mm, but not more than 20 mm.

- Diamond drill bits - small elements with annular diamond edge. The depth of the hole when drilling by them can reach 45 cm.

- Diamond drills - These are feathers and cones of small diameters. The area of their application - from deep technological drills to engraving (on a stone basis).

Additional tools

Professionals involved in drilling porcelain, can use additional equipment: ballerina, a centering device for diamond crowns, a centering device for a diamond drill-crown, a conductor, a cylinder for liquid temperature reduction of diamond crowns or drill-crowns. To work necessarily need a screwdriver or drill, perhaps - the holder for the drill.

Ballerinas are used in cases when it becomes necessary to drill a very large hole in the ceramic granite tile. They are fixed in the drill in the same way as the drill.

A centering device is used to prevent crown displacement. For one-time work, it is permissible to quickly manufacture the device from plywood or wooden pieces (with drilling holes of the required size into them).

The conductor is a professional device for the most accurate perforation of porcelain tiles. Its purpose is to precisely guide the drill to a given point. The cylinder for liquid temperature reduction of crowns or drill-crowns is designed for cooling with a constant flow of water.

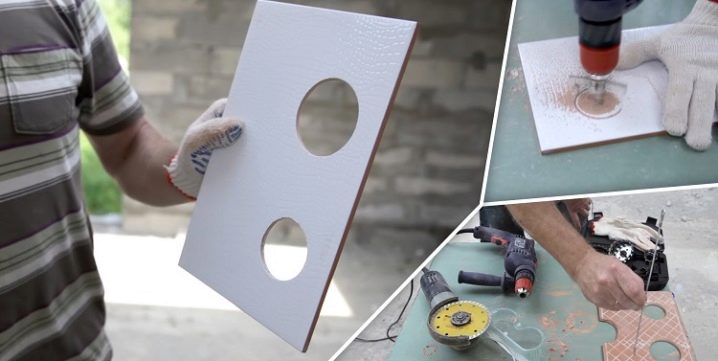

How to drill?

It is recommended to drill the ceramic granite slab from the front side. To more economically use the resource of the drill, the holes are sometimes drilled by 2/3 of the thickness of the tile, and the remaining third simply get knocked out by a strong blow.. At the same time on the back surface of the tile often occur chips. They should be invisible, so the tiles should be drilled directly from the face. The resulting chips should not be scary, because then they can not be seen.

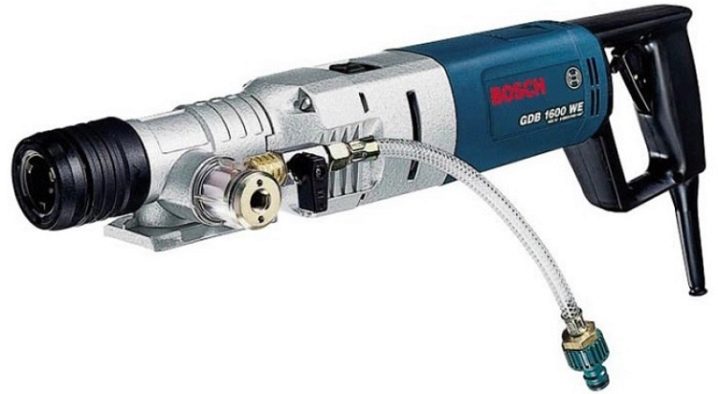

For perforating porcelain tiles, it is better to use a drill press or drill stand.. Thanks to such devices, the life of the drill increases and the work is greatly simplified, and the hole is beautiful and accurate. Drill must use 2-speed, as when perforating porcelain stoneware with a diamond drill, considerable rotational speed is not required.The use of a hammer drill is not recommended because the stove may crack. If you are using a hammer drill, you need to turn off the shock function.

Before you start drilling, do not forget to enclose the fiberboard or plywood plate under the porcelain stoneware, so as not to accidentally damage the surface of the floor or table with a drill. The drill should be directed only vertically, it should not be allowed too pronounced slope in relation to the plate.

Wet

When working, diamond drills are prone to heat, and they require cooling to increase their service life. At home, the auger can be cooled using a container with water covered with a lid. Several small holes are made in it, and water is fed in small portions to the drill. For these purposes, you can also use a special cylinder. This method is called “wet drilling”.

If the work is done correctly, a carefully drilled element falls out of the plate, corresponding to the diameter of the drill. Of course, it is more convenient to drill a recess in a ceramic-granite tile on a table or on the floor when it is removed. It is much harder to do it right on the wall. You can use the crown or ballerinawithout placing a hole too close to the edge of the tile.

Dry

There is also the so-called dry drilling of porcelain. It is used in cases where it is necessary to obtain a large number of holes in a relatively short time (and with impressive volumes of construction work).

Inside the drills, designed for such drilling, is olive oil. At the beginning of work it is necessary to keep the drill not at a right angle. It is necessary to bring the tool to the treated surface with an already rotating drill. This is necessary in order not to damage the tile surface.

When the drill warms up, you will need to change the angle to a straight line, then you can continue to work. It is worth avoiding considerable effort. It is better to work at 1,5 thousand revolutions, it is necessary to cool the product. When heated while drilling, olive oil protrudes, helping to cool.

It is important to understand the following: after the start of work, the stop is extremely undesirable, since the drill and the cooler will have time to overcool. They will have to reheat, which will reduce the service life of the tool.

Tips

When working with the tool should take into account some useful recommendations. In this case, you can achieve remarkable results.

Under the toilet seat

To make a hole for the toilet mount in the ceramic granite tile already on the floor, it is necessary to use a diamond crown. Usually it is a crown D 10 mm, which should be used with water.

With such a crown, you must work with a special additional tool - the conductor. If the jig is missing, you can do it yourself by drilling the corresponding hole in the plank.

Then you need to make a mark on the porcelain. Align this mark with the hole in the jig and start drilling. After some time, you can remove the jig and continue working without it. Having drilled the ceramic granite plate to the end, it will be possible to replace the diamond crown with an ordinary drill and drill a hole for fixing the toilet bowl with it.

Under the socket

It is recommended to make a hole for the floorboard before the tile is laid. A marking is drawn on the front side of the ceramic tile,A mark is made in the center of the intended hole with a small diameter drill. Then a large-diameter diamond crown is taken, which is necessary for installing the socket. Then the ceramic granite is drilled through.

To prevent the instrument from overheating, use water.

Manufacturers

It is recommended to purchase products of those manufacturers that have earned the trust of consumers. To avoid mistakes, you can focus on customer reviews that they leave on sites.

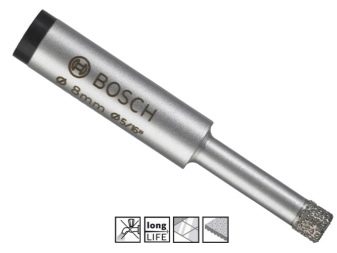

- Bosh. It produces high-quality and best-selling among the specialists of drill bits and porcelain stoneware bits. The high price of Bosh tools is always justified by the durability of the products. Professionals prefer this brand when choosing self-cooling drills for dry drilling with olive oil.

"Monolith". Russian manufacturer of diamond-coated crowns and drills, manufactured by diffuse method (with water cooling). The price of Monolith products depends on the size of crowns and drills. This manufacturer produces products up to 70 mm.

- Hawera. It is one of the oldest European manufacturers of drills. Such products are of high quality and long service life.The tool is produced by vacuum soldering and works on self-cooling. As a rule, all Hawera drills and crowns are distinguished by an optimal ratio of price and quality - this advantage attracts a large number of consumers.

For information on how and how to drill porcelain, see the next video.