Steps of porcelain: the pros and cons

Porcelain tiles are considered one of the most reliable and high-quality ways to create all kinds of steps for stairs. The mechanized characteristics of porcelain stoneware allow it to be used for similar purposes.

Material Features

Porcelain stoneware is a fairly durable material, which today is very popular. Among the features of this material are the following positions:

- Moisture resistance. This property of ceramic granite does not allow it to absorb moisture. On such material will never appear cracks.

- Wear resistance. Ceramic granite slabs will retain their original properties for many years and will be able to serve up to 50 years.

- Chemical resistance. The material is not affected by chemically aggressive compounds.

Advantages of ceramic granite:

- is an environmentally friendly material;

- material incapable of fire;

- keeps shine throughout a large amount of time;

- does not require special care;

- does not undergo chemical influence, therefore its strength and durability is guaranteed for a long time.

Requirements

Choosing such material for the stairs, you need to pay attention to its performance. Thus, you can choose a better material. Primary requirements:

- radioactivity - 1Ra less than 1 or 1Ra equals 1;

- glossiness - more than 55 or 55;

- frost resistance - no breaks and cracks after 50 tests;

- resistance to sudden temperature changes - there are no kinks and cracks after 10 cycles of freezing followed by heating;

- wear resistance - less than 175 mm2;

- water absorption - less than 0.5%;

- evenness of the sides - 0.2%;

- squareness - 0.2%;

- surface smoothness - 0.2%;

- thickness deviations - 5.0 mm;

- deviations in width - 1.0 mm;

- deviations in length - 1.0 mm;

- elastic modulus (fracture strength) - less than 35 MPa.

The steps for the porch must be chosen from a durable material.

Types and sizes

The following types of material are distinguished:

- Double backfill. This view consists of two layers: the bottom (in color) and the top (unpainted). Such an approach gives the material sufficient strength and good resistance to various influences.

- Matt. The peculiarity of this variety is that the porcelain stoneware does not undergo polishing - it undergoes only minimal changes. Accordingly, the price of such material on the market does not exceed the average.

- Polished. Such a product is polished to a perfect shine. This type is most often used in exhibition halls, cathedrals, restaurants, and other similar institutions.

- Lapped. The structure of the material is divided into two parts: one is polished and the other has a matte shade.

- Satin finish. This variety is exclusively polished and is no longer subject to other changes, retains its structure for a long time.

- Technical. The material has the appearance of ordinary natural granite. Differs in its simplicity and affordability. The structure of the material does not change with time.

- Glazed. The main layer of this type of material has a glaze coating, which is roasted during the production process.

It is also necessary to carefully select the size of the material.

The following sizes of porcelain stoneware are distinguished: 30x30, 45x45, 60x60, as well as 120 by 30 cm. Plates of 300x1200 mm are often used for lining areas in front of world-wide buildings. The minimum size is considered to be 5x5 cm, and the largest - 120x360 cm. But, regardless of generally accepted standards, you can create your own individual size.

The following sizes are most commonly used: 1200x300, 1600x300, 1500x300 mm and 30x30 cm. This can be explained by the fact that you can always make small tiles from large sizes by fitting them to the required size. For example, from a tile length of 1200mm, you can cut two by 600 mm.

Frequently selected species:

- with capinosis;

- monolithic;

- roadside;

- lengthy.

The thickness of the porcelain tile is almost irrelevant, because a well-laid 4-mm tile will not differ from a 45-mm-thick tile - this material can withstand a large weight load (for example, 8-mm thick ceramic granite can hold a huge weight of 192 kg / cm²).

The material is used in most places of urban infrastructure: shopping centers, cinemas, train stations, airports, cafes and restaurants, hospitals and schools. Often porcelain stoneware is used in covering bathrooms and swimming pools. This material is one of the most popular and frequently used. Therefore, the choice of the buyer often falls on the porcelain tiles, rather than on ceramic tiles.

Design

When choosing the surface of the stairs, it is necessary to determine its basis, therefore it is important to make the right choice and choose the right design that will make it much more beautiful, because presentable buildings cannot do without a beautiful appearance. The following forms of ceramic granite are distinguished:

- square;

- unusual shapes: triangle, polygon, polyhedron, and other non-standard geometric elements;

- decorative components;

- mosaic shapes;

- separating friezes;

- small bricks;

- panels of rectangular shapes;

- grid.

There are several options for laying porcelain stoneware material.

The traditional option and "scramble"

It assumes standard stacking in the profile: vertically and horizontally.Laying is performed parallel to the railing. In this case, it is better to choose colors neutral or from one palette. Rectangular stoneware is often used during sticking.

Christmas trees

The Christmas tree element is one of the frequently used ways of laying stairs for stairs. In this case, a feeling of front parquet layout is created. In this approach, most often used satin porcelain stoneware, which looks like a real tree. Typically, this material is used in laying stairs to give.

Individual design development of porcelain tile will allow consumers to choose their size, pattern, color, pattern, location. It is recommended to use porcelain stoneware plates with a satin finish. Such plates are able to undergo any modifications. Porcelain stoneware flooring is made in a different format, but in the same color scheme.

It is important to take into account the correct location of the plates: there must be a correspondence of sizes and lengths. Any inaccuracy and error in laying can lead to the displacement of elements and the appearance of unwanted cracks.In such a case, it will be necessary to re-dismantle such a cover for the steps.

Diagonal tile laying

The laying of porcelain stoneware is performed with accurate marking of the diagonal axes. The ideal option for such a coating is monochromatic or contrasting stoneware tiles.

Interior designers advise to use porcelain stoneware coatings, developed individually, so they look expensive and tasteful. If you want to show originality, you can use a modular coating. This option allows you to perform lining in a single and individually selected instance. The Russian market provides a lot of designs, sizes, patterns of ceramic granite plates, so there should not be any problems with the choice.

When choosing a tile, it is necessary to take into account the peculiarities of the stairs: its width and size. It is important to pay attention to the features of the plates, because some options require special care, and, accordingly, there will be more problems.

Designers are advised to choose plates that are easy to maintain, but they are not without a kind of elegance and high cost.

Equipment

Porcelain tile has a number of advantages: from the ability to smooth the influence of weather and climatic conditions to protection against deformation of the plates (the appearance of cracks and deposits). Surfaces are of the following types:

- Matte. Due to the main polishing of the plate is not polished, so this version of the product is the cheapest option. The simplicity of such material allows it to be used in construction with a minimum budget.

- Glossy. In the production process, polishing is not the final stage of plate production, since after this procedure the plates are still polished. Only the top layer is polished. Due to this method of manufacturing, the material becomes a more expensive option for facade slabs.

- Satined Such plates can have different colors due to burning and the subsequent application of a layer of mineral salts on them.

- Half polished. In the process of manufacturing there is an incomplete polishing of the plates. It uses a large base tool to make the surface of the product of the appropriate type, due to which the cost of manufacturing is minimal, and, accordingly, the price does not exceed the average.Such material is famous for its durability and high water resistance.

- Structured. This type of material is made by polishing method, while the product has the appearance of a natural stone.

Professionals recommend using plates 60x60 cm - this is the most reliable and profitable option for the buyer. According to statistics, most often used slabs polished or matte porcelain, as well as a structured version - it is acquired by 83 customers out of 100.

The minimum cost of polished or matte porcelain stoneware is 1000 rubles - this price allows you to purchase mostly these types, which makes them the most sold and used.

When buying porcelain tiles for stairs, you should pay attention to the following points:

- method of burning plates;

- the amount of friction of the surface;

- frost resistance;

- fundamental nature;

- material width;

- shutter speed of the material, its strength when using;

- category of use;

- the ability to withstand all kinds of abrasion;

- the difference in shades of the plates;

- the use of material containing precious metals: gold, silver and platinum.

Such porcelain stoneware has no restrictions on operation, like natural granite retains its properties for many years, avoiding breakage and cracking.

For stair steps you can use marble, which has white inclusions. To him you need to find a beautiful baseboard.

Tips for choosing

There are 3 rules that will help not to be mistaken in the choice of ceramic granite slabs:

- high-quality ceramic granite has shallow squares on the back side, therefore, as soon as the tile falls into the hands of the buyer, it is necessary to carefully inspect the back of the product and check it for the presence of squares. A similar element is made in order to ensure good adhesion of the tile to the stairs;

It should be noted that at present there is a tendency not to indicate the name of the brand on the plates - manufacturers are limited to the inscription of the country where this material is made. Therefore, do not be afraid of the absence of the manufacturer on the packaging.

- choose porcelain stoneware by weight: the thickness must correspond to a certain weight category;

- you need to pay attention to the rules of operation and installation of porcelain stoneware (surface type, weight,wear resistance).

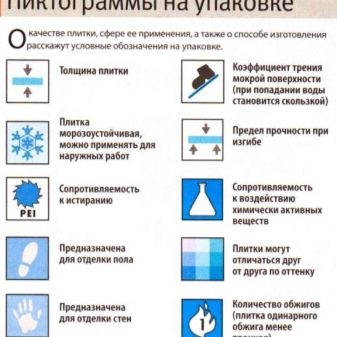

Attention should also be paid to the labeling conditions:

- information on the package is required;

- a foot on a black background indicates that the package contains a floor covering that is suitable for a ladder;

- a foot on a mesh background means that the material is highly durable;

- the snowflake sign means that the products are frost resistant.

Beautiful examples

The porcelain stoneware staircase looks very elegant. In combination with her wrought iron railings look even more elegant.

Polished porcelain - a modern solution. The stairs have a beautiful shine and are suitable for many interior styles.

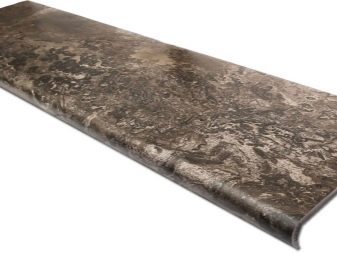

The structured steps resemble a raw stone. Their surface has a roughness and therefore does not slip at all.

How to lay porcelain stoneware on the stairs, see the following video.