Features of the alignment of the walls of drywall

Modern design opens up great opportunities for decorating your home, but for decorative decoration to look beautiful, the surface of the walls should be even and smooth. To date, there are many options for alignment of the walls, while their plasterboard is very popular. This type of material allows not only to hide all the defects of the coating, but also is an excellent sound and heat insulation.

In addition, the alignment of surfaces with drywall is not particularly difficult, it can be done independently. To do this, it suffices to select the desired thickness of sheets and apply a simple plating technology.

Special features

Drywall is a multifunctional building material that is widely used for leveling walls. Prepared surfaces can be covered with any kind of finish: paint, tile, wallpaper or plaster.The main feature of the material is that during its installation a small space is created between the walls and the sheets, in which communications and noise insulation are usually placed. Thus, the foundation takes on an aesthetic appearance, and all its flaws are hidden.

The leveling of the walls with plasterboard is especially well suited for small apartments, where using unique projects, in addition to covering the overlap, you can make stylish shelves and built-in niches. Such designs are an excellent addition to the wall decor and harmoniously combined with the overall design of the rooms.

Before starting the installation, it is necessary to choose a suitable method for installing drywall, since it depends not only on the type of finish, but also on the features of the fixed floor, as well as the operating conditions of the future structure. As a rule, wooden, brick and reinforced concrete walls are sheathed with material.

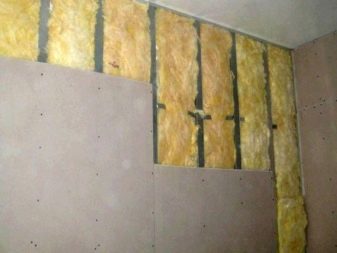

The framework on which the sheets of drywall are fastened can be either metal or wooden. This alignment method is suitable for surfaces whose flaws do not exceed 20 mm. If the irregularities and dimensions of the defects are large, then at first the walls are puttied and only after that the sheets of material are laid.

Advantages and disadvantages

Many masters choose drywall to prepare the walls for decoration, and this is not in vain, because it manages to avoid time-consuming work with plaster, which requires the preparation of a large amount of mortar. In addition, the dry alignment of surfaces takes a little time and is much more economical. With proper mounting of the sheets, the walls become perfectly smooth, the electrical wiring can be hidden in their cavity, and lamps can be installed in the niches. Therefore, the best option for a complete decoration of the grounds is not found.

In addition to the above advantages, this alignment has the following advantages:

- good heat and sound insulation;

- ease of installation;

- possibility of additional decoration.

As for the shortcomings, they are few.

- The material is fragile, so heavy walls should not be hung on walls lined with plasterboard. You can increase their strength by reinforcing the frame.

- Finishing of surfaces is sometimes accompanied by puttying.

Therefore, if during repair it becomes necessary to level the walls, then it is best to give preference to plasterboard plating,This will significantly save money on material and hired labor, since the work, in contrast to puttying, can be done with the hands of even a novice master who has no experience.

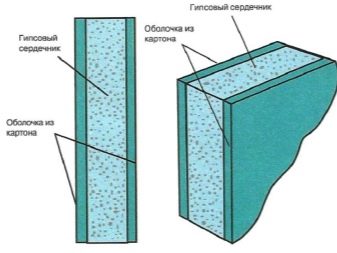

Types of FCL

Gypsum board is manufactured in the form of flat sheets, the main components of which are gypsum and special modified additives that improve its technical properties. The material has high quality, durability, has a low weight, conducts heat well and absorbs sounds. Gypsum board used for wall finishing is usually produced with “closed” edges of the sheet, they can be straight and thin.

Due to this unique structure, the material plays the role of not only the front wall cladding, but is also suitable for cladding multilayer structures. There are also sheets with a semicircular and open edge, they are chosen for finishing seams.

To date, the construction market is represented by a huge range of drywall, which differs in size and scope of application. The main types include several types of GCR.

- Standard. The most popular type of material.It is used for leveling walls in rooms with a normal level of humidity and temperature.

- Moistureproof. The product is characterized by low water absorption, therefore it is suitable for work both in dry rooms and in rooms with high humidity. Sheets of such drywall are made using a special technology, they contain special additives in their composition, which reduce the absorption of moisture and prevent the appearance of fungus.

- Fire resistant. Reliably protect walls from destruction in case of fire. The main components of the material are reinforcing fibers and mineral additives that provide sheets with fire resistance.

- Water-resistant. Drywall is well resistant to moisture and resistant to fire.

- With increased strength. It is used for cladding walls in rooms that are most susceptible to mechanical stress. In contrast to the standard type, it has a dense structure, since it consists of several durable layers of cardboard and reinforced fiberglass.

- Restoration. The thickness of the sheets is 6.5 mm, so this installation does not take up the useful area of the space during installation, perfectly hides irregularities and can act as embossed wall decoration.

Scope of application

Often during repairs, many homeowners are faced with the problem of uneven surfaces, especially as regards the walls. Therefore, in order to qualitatively prepare the base for further finishing, it is necessary not only to eliminate the cracks and various flaws, but also to make the coating perfectly smooth. The correct solution in this situation will be the alignment of the walls with the help of drywall, which can be used both for decoration in the apartment, and in a private building. This way you can sheathe the surface in a wooden house, if you plan to tile or glue wallpaper.

For the frame of the log house, a wooden or metal frame is installed first and the structure is attached to it, after which any design can be performed in the room.

Plasterboard is also covered with clay, brick and concrete walls. Moisture-resistant sheets are used for base plating in the bathroom and in the kitchen, as the material will be exposed to the negative effects of moisture. Drywall is also suitable for covering toilet walls, balconies, loggias. On it you can put as a tile, and perform decorative trimming with other materials. At the same time between the surface of the ceiling and the floor need to leave a small gap of 5 cm, this will improve ventilation and prevent deformation of sheets that can shrink.

In addition to residential premises, drywall is also used for interior wall cladding in garages and warmed gazebos. To do this, choose products with high strength. Fire-resistant material is chosen for cladding walls located near the fireplace, they withstand high temperatures, are resistant to fire and are to be decorated with stone.

Installation

Fixing sheets of drywall is performed on a previously prepared base, so before you align the walls with your own hands, you must do all the measurements and make calculations. In addition, the following tools are required for installation:

- laser level;

- roulette;

- plummet;

- hammer;

- Bulgarian;

- scissors for metal;

- screwdriver;

- plane;

- rail;

- knife;

- spatulas;

- sandpaper;

- capacity for priming and cooking putty;

- rollers and brushes.

To level the walls using drywall, you should also determine the method of installation. Today, both frameless version is widely used (drywall is fixed on glue, cement or gypsum), and frame technology,in which they make a wooden or metal frame. Both methods are good and equally allow you to eliminate the uneven surface, but if you do the work yourself, then it is important to fix the sheets correctly so that the installation is of high quality. Therefore, step-by-step instructions will help beginners in this.

Installation without frame

First of all, the surface of the walls is checked, it must be durable, dry and free from flaking elements. If the base is covered with oil paint or enamel, then it is thoroughly cleaned from the old finish. Since the material will be mounted on plaster glue or cement-polymer mixture, the overlap is additionally coated with a primer.

This technique is only suitable if there are slight level drops in the walls.. It will also be necessary to make the insulation of the structure, in this case foam is used as thermal insulation.

The main advantage of this method is that the work requires a minimum set of tools, the sheathed wall does not reduce the living space and the surface will serve as an excellent sound insulation. After the base is prepared, the glue is evenly applied over the entire base of the plasterboard and the sheet is fixed to the wall.

Installation with frame

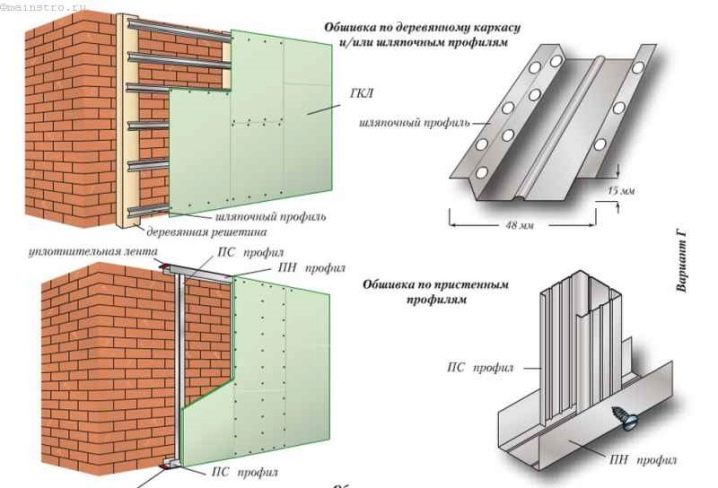

It is the most reliable and high-quality option for leveling walls. First of all, the skeleton of the structure is made with the help of a wooden bar or metal profiles. As a rule, the frame method is chosen if it is necessary to sheathe surfaces with large flaws or create complex compositions in the form of arches and niches.

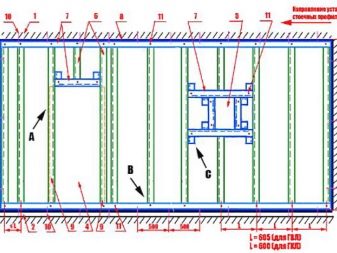

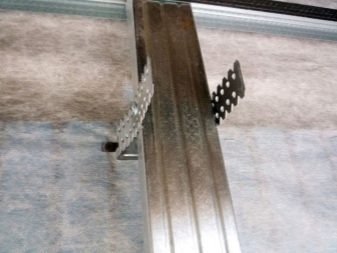

To prepare the metal frame, use special profiles made of galvanized steel, they are equipped with through holes and a notch, thanks to which the fixing of parts is carried out conveniently and quickly.

Sound insulation with this installation will be weak, so you need to additionally consider measures how to increase it.

The main disadvantage of the frame installation is that it is carried out using a large number of tools. But the metal frame, which is attached to the drywall construction, moisture resistant and durable. And also under the sheets you can lay not only a layer of insulation, but also hide all communications.

As for the wooden frame, it is made from a flat and dry timber, which is characterized by good sound insulation, durability and acts as an excellent thermal insulation. After the assembly of such a frame, the bars must be treated with special impregnation., it will protect the tree from bugs, mold, moisture and rot.

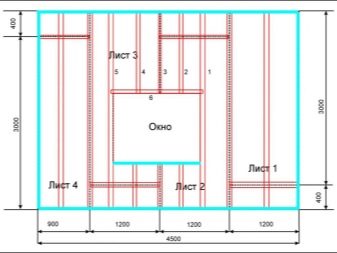

The first step in the frame installation is the marking of the walls. For this, the distance from the angle is measured, a gap of 5 cm is left and a vertical line is drawn. A similar procedure is performed with the opposite wall, then the rail is taken and the resulting lines are connected to a point on the floor and ceiling. After that, vertical markings are made from the corner and lines are drawn, the distance between the marks should not exceed 60 cm.

Simplify the work will help the laser level, through which you can quickly mark the vertical and horizontal lines.

Measurements should be performed accurately, as the slightest mistake will cause improper installation. Additionally, the lowest point of the ceiling is also determined and lines are drawn from it onto the walls. It is important to measure the distance between the walls on the inside corner. At frame installation the wall "will take away" the useful area in 4 cm, This should be taken into account, and if the room is small, then this method is best not to choose.

The next step will be mounting profiles along the marked lines. They are fixed around the perimeter of the wall with screws. The final stage is considered plasterboard plasterboard. To do this, depending on the level of humidity and temperature, a certain type of material is selected, and it is attached to the frame with screws. Then all the joints are filled with putty, and the surface is primed.

It is worth noting that both the first and the second method will be suitable for self-leveling of the walls with drywall. But before you decide on the installation, it is important to take into account the microclimate of the room and the level of defects.

Tips and tricks

Curved walls often serve as the main reason for the failure of a beautiful finish, but today this problem is solved. To eliminate the irregularities and defects of the old base, you can use drywall. Its installation is much cheaper than puttying, and does not require special skills in the work, so many homeowners sheathe the walls themselves.

If the alignment is done for the first time, then the simple experts will help the novice masters to correctly perform it.

- You can attach both solid sheets and their pieces. Often the rooms have an irregular shape, so you have to impose on the walls of the structure, consisting of chopped drywall. To cut the material, you must first cut one layer of cardboard, then slightly cut the core, after which the second layer will become available. This operation is best done with a sharp knife with a trapezoid blade.

Walls sheathed in this way will have joints on the surface, they should be sealed with a putty and primed.

- You can ease the tack sheet to the frame by following these steps: a sheet of material is placed vertically, then it is brought to the structure and slightly fixed with screws. You will need a partner for the work, as it will be difficult to press the drywall and simultaneously fasten it. Then, when the sketches are made, the sheet is checked by level and finally screwed to the frame.

- Do not install drywall close to the floor and ceiling.. It is recommended to leave small gaps, because the material sometimes shrinks, and if this is not done, the sheets will be deformed.

- When installing between screws, it is necessary to take a step of 20 cm. At the same time, the caps of the screws must be well screwed so that they do not interfere with the finishing. Fix the hardware carefully. In that case, if you make the maximum efforts, the screw will tear the top layer of drywall and will not hold the sheet. When this happened, then next to it you can tighten another safety screw.

For how to self-level the walls with drywall, see the following video.