What should be the thickness of drywall?

Recently, a truly unique in its kind finishing material gypsum board is gaining more and more popularity. And this is not surprising, because with it you can align walls, construct a ceiling surface, install built-in wardrobes and shelves, as well as create partitions of any geometry. Each design requires not only careful design, but also the correct choice of drywall.

Special features

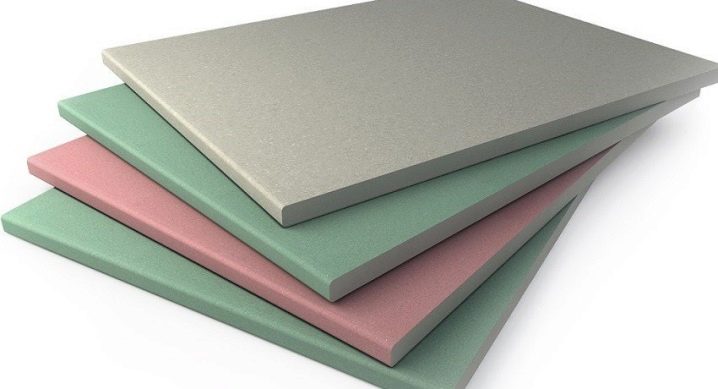

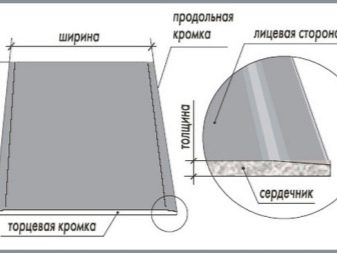

The classic version of the material is a sheet obtained by pressing, consisting of a gypsum core and two layers of cardboard covering the base layer on both sides. Modification or varieties of GCR depend on the scope of its application, which is fundamental in the development of sheet thickness.

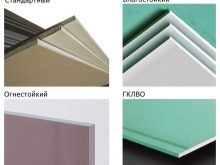

According to the classification, the thickness of the product determines the place of use. Wall view Drywall refers to the most common types of this material. Covering the wall, creating an interior partition is carried out with the help of this particular type. The thickness of the wall sheet depends on the loads imposed on it.

If the partition to be built will perform only a decorative function in the future, then it is not necessary to install thick sheets, it can be limited to less thick compared to wall-mounted or intended for installation in an interior partition with a door.

Ceiling view drywall compared with the wall has a smaller thickness, and there is a simple explanation. The material, regardless of the type of construction, is attached to the suspension frame, therefore, in order to prevent collapse of the structure, the sheets should have less weight than those intended for partitions and leveling the walls.

The most subtle types include arched GCR. It is used if you want to make a structure with curved shapes. Due to the smallest thickness compared to the ceiling and wall types of drywall, allowing it to bend, it is possible to assemble models with wave-like, dome-shaped or round shapes.With the help of an arched plasterboard you can create structures even with the smallest bend radius without creases. This type differs from all not only in thickness, but in composition, instead of a paper layer, it has layers of fiberglass, which give strength to the sheet, as well as affect its weight.

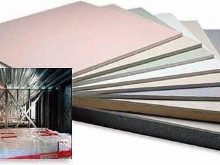

There are other parameters that characterize drywall and affect its thickness. Depending on the climatic parameters and the functions imposed on the design, the GCR includes various components due to which the sheet becomes resistant to various types of impact.

Moisture-proof sheet marked as WGL and has a green surface color. It is used for structures installed in rooms with a high level of humidity. Its resistance to water is explained by the presence in the composition of a hydroprotective solution, impregnated impregnation, stopping the rate of absorption of moisture and antifungal agents that prevent the occurrence of mold. The use of VGKL in bathrooms, swimming pools, bathhouses is also justified by the fact that it has a sufficient thickness to veneer the surface with ceramic tiles or artificial stone.

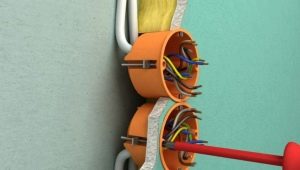

Fire resistant sheet, marked by manufacturers as GKLO, has a pink color. The composition, in addition to gypsum, includes components such as fiberglass and clay, and also contains liquid in the form of crystals. Each component has its own purpose. The crystallized liquid prevents the spread of fire, and fiberglass and clay help preserve shape after burning cardboard layers. The fire resistance of such a sheet is within 45 minutes from the time of ignition. This type of sheets is used if you need to make a ventilation shaft, an air duct, a portal for a fireplace or a duct for electrical wires.

Sheets with markings GKLVO have all the qualities characteristic of moisture-resistant and fire-resistant species.

A special type is gypsum fiber sheet or GVLcharacterized by increased strength. In addition to gypsum, its composition contains cellulose fibers, thanks to which it is able to withstand considerable weight loads. Another distinctive feature of the fiber product is the absence of cardboard layers. A variety of conventional fiber sheet is GVLV, which can withstand not only significant loads, but also is resistant to moisture.

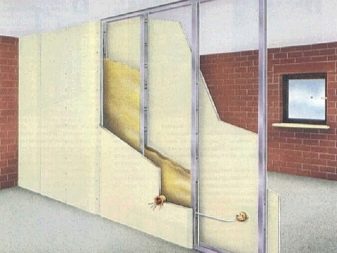

These types of drywall belong to the main groups that are more in demand and more often used. But there are other species in which thickness is of particular importance, since the scope of their use is specific. The composition of these sheets contains additional layers, which determine their purpose. Noise isolators, heat insulators, absorbents of electromagnetic waves, as well as products with the function of protection against wind, used in facing buildings, have a dense structure and have a higher thickness than conventional sheets.

Advantages and disadvantages

Plasterboard sheets occupy a leading position among other finishing materials is not by chance, they have many positive qualities, thanks to which they gained their popularity.

It is quite simple to work with them; a person without special professional skills can cope with the installation of a conventional design. It is easy to cut and fasten to the frame, the main thing is to make the preliminary marks correctly. Thanks to various types of sheets, it is possible to assemble not only simple box shapes, level walls and ceilings, but also to build beautiful partitions with arches, to install two- and sometimes three-level ceilings, using various copies in thickness.

Sheets of plasterboard, regardless of the application, have little weight, and therefore the structures erected from them do not put pressure on the floor, if installed in an apartment, and do not have a negative impact on the foundation, if the structure is installed in a private house.

Regardless of the components that make up the gypsum board, this material is fire safe, because the basis of any sheet is gypsum, and it does not belong to combustible materials, on the contrary, it contributes to the attenuation of an open flame and does not extend it to other materials. Fire safety is the main argument in favor of the construction of fireproof walls in rooms.

Any types of drywall, regardless of thickness and purpose, belong to environmentally friendly finishing materials, they do not contain components harmful to human health, which means that it is possible to assemble structures made of gypsum plasterboard in any premises.

But this material has its drawbacks.Due to the fact that the basis of drywall is still gypsum, its strength is not as great as we would like. It will not be possible to use the surface of the sheet for hanging items with an impressive mass. Shelves made of solid wood with a large number of books, wall cabinets, plasma panels and other items weighing more than 10 kg require, as a rule, special fasteners, and if the mass of the object is above 35 kg, then fastening is possible only to more durable materials.

Do not forget that gypsum, which is the basis of any sheet, has a high degree of hydrophobicity, so there is always a risk of loss of form due to disintegration.

Even moisture-proof sheets can lose their rigidity with direct and long-term contact with water, not to mention the usual gypsum boards, so all types of structures constructed with the help of plasterboard sheets should be located indoors.

Dimensions

The application of drywall is very extensive. Given this fact, manufacturers produce sheets of different thickness, width and length. When buying sheets, it is necessary to take into account all the parameters and select the material based on the location of the future structure.

Plasterboard sheets do not differ in special diversity in width and length. The length of sheets produced by manufacturers, today is in the range of 2-4 m. Such a run-up is due to the difference in the height of the ceilings in the houses. The standard is a height of 2.5 m, but products with a length of 2.7 and 3 m are no less popular and in demand. Less often on sale are specimens with a length of 3.5-4 m, they are usually made to order.

The width of the sheets are of two types - it is 0.6 and 1.2 m. The less popular and demanded width is 0.6 m. The second value of 1.2 m is more common and is used therefore it is considered to be its standard.

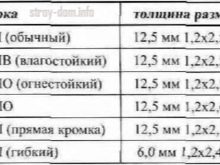

The run-up of the thickness of the plasterboard sheets is in the range of 6-24 mm, but there are products and more dense, used mainly for finishing floors, their thickness reaches 50 mm (maximum). The thinnest specimens have a wall thickness of 6-6.5 mm (minimum size), used to build structures with bends on the ceiling surface.

For walls, sheets having a thickness of 12–16 mm are used, and 9.5 mm is enough for a ceiling. The optimum thickness for a gypsum construction is 12.5 mm.

The use of sheets of different thickness depending on the location makes sense, because the thicker it is, the more weight it has,which means that the higher the design, the thinner the sheets will be required for installation.

How to choose?

In order to choose the right drywall, first of all, its purpose and the load planned for it are taken into account.

If it is necessary to install the structure in the bathroom, then it is best to purchase moisture-proof sheets (SCLV). The thickness of the product should be selected according to the location. For niches and partitions, sheets from 12.5 mm to 15 mm are most suitable, and for the ceiling surface sheets with a thickness of not more than 9.5 mm with a similar resistance to moisture. You should not be reinsured using products with a thickness of more than 9.5 mm for the ceiling surface, since there is a probability of collapse of the installed structure, because sheets with a thickness of 12.5 mm have a greater weight. In addition, their cost is slightly higher, and therefore, money for the purchase of material will be spent much more, and in case of collapse - for nothing.

To create a two-level ceiling with bends and arches, you should purchase a special thin arched gypsum board, and for ducts with simple shapes, the usual ceiling one will do.

For outdoor work and in rooms with a high degree of humidity, gypsum-resistant, moisture-resistant sheets (GVLV) are more suitable.

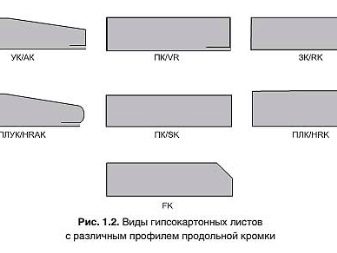

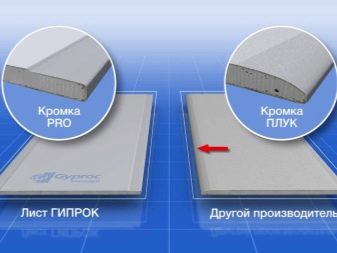

Selecting sheets in thickness, it is necessary to pay attention to the edge of the material. Different types of edges are produced by manufacturers not by chance. The subsequent processing of the joints depends on the type of edge the sheet has.

Instances with a straight edge are needed if the construction lining is conceived as a two-layer, and they are used as the inner layer, where you do not need to glue and putty the joints. Products with refined edges are purchased if you plan to use reinforced tape at the joints in the future. For sheets with a rounded edge with a width of 5 mm, the use of reinforced tape at the joints is not necessary if it is not planned to apply a putty to the entire surface of the sheet.

When selecting sheets, it is important not only to take into account their purpose and location, but also to correctly calculate their consumption. Knowing the area of the lining construction, it will not be difficult to do this.

The partition wall sheathed with plasterboard with a size of 5x 2.5m has an area of 12.5 m², and the area of one standard sheet with a size of 1.2x 2.5 m is 3 m².In order to form a partition, the frame is sheathed on both sides, which means that the area covered by the sheets is doubled and becomes equal to 25m². The number of sheets required is calculated as follows: 25: 3x1.2 (correction factor). The resulting number is rounded up in a big way, in our case 10 sheets will be required.

If the structure needs to be sheathed in two layers, then the area of the structure should be multiplied by 4. For ceiling surfaces, the consumption is calculated in the same way, and for mounting the side walls located along the perimeter, a few more cm are added, usually 10-12 for each sheet width.

Tips and tricks

By the choice of high-quality gypsum sheet should be approached very thoroughly and very deliberately.

When focusing on the purchase of sheets on the parameters, you should know not only the amount of material, but also take into account the dimensions of the room in which the structure is mounted. In small rooms with low ceilings and a small area it is very difficult to work with sheets that have large sizes. It is better to purchase products with standard sizes, especially if the installed design does not have pronounced specificity.In addition, the cost of such sheets is significantly lower than that of large-sized copies.

For the same reason, you should not spend money on products with specific properties, if there is no reason to. Fire-resistant and moisture-resistant material is more expensive than usual, and the sheathing of the structure, which is located in a place that is dry and distant from fire and water, will do nothing except extra expenses. It is better to get a regular drywall with a thickness corresponding to the location.

Buy drywall should be from proven and well-proven companies specializing in building materials and providing a long-term guarantee while complying with operating standards.

It is not necessary to purchase material in natural markets, there is a risk of purchase that does not meet the stated specifications, and storage conditions in such places are usually violated, which invariably leads to a decrease in product quality, which, in turn, affects the lifetime of the whole designs.

About the partition of the minimum thickness: 50mm and installation of drywall, see the following video.