Drywall Sizes: Standard Length and Width

Modern repair requires materials that would give maximum opportunities, this is what drywall is now. With it, you can build walls, partitions, level the surface, do all the things that decorate, change and transform living space.

To work correctly with such a material, it is important to know its features, and to calculate the quantity, it is necessary to understand what are the sizes of drywall sheets.

Types of material

Gypsum board as a composite material has found application in the repair of a wide variety of premises, it is used to create new structures, improve existing structures and change the structure of the premises thanks to extensions,piers and partitions. To properly use this material, you must be able to select it for a particular type of work.

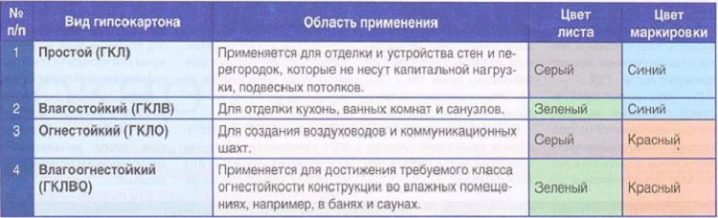

There are several types of drywall:

- UsualWhich is marked with the abbreviation GCR. Inside the product there is gypsum dough, which is covered on both sides with thick cardboard. It is most convenient to use such sheets for interior decoration. It is important to apply them where the humidity will not be increased, otherwise the material will swell and lose external qualities, which will affect the reliability of the whole structure. It is convenient and fast to work with sheets of this type, they are not heavy, flexible and economical.

The most common area of use is working with the ceiling, less often with the floor, but most often it is taken just for walls, to level them or create new ones.

- Fire resistant, which is called GKLO, is most favorable for use in non-residential premises, creating partitions. With it you can protect the space from the threat of fire, which allows it to be used for fireplaces and stoves.

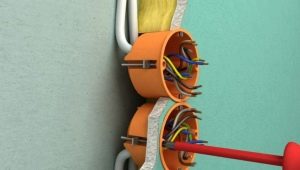

- Moisture resistant, has the designation GKLV, is used in rooms where the level of humidity is significantly increased, this is a kitchen and a bathroom.To ensure such properties, substances are added to ordinary drywall that help to absorb moisture, thereby preserving all the characteristics of the sheet. This option is well opposed to the formation of mold and fungus on its surface. If the rooms have too high levels of humidity, it is recommended to use another finish for them, because drywall will deteriorate due to excessive moisture.

- Fire and moisture resistant, marked with GKLVO, is characterized by the presence of resistance to both fire and water.

If you need to build special building structures, you can select additional types of material that have different levels of thickness, these are:

- arched 6.5 mm thick;

- ceilingwhich has a thickness of 9.5 mm;

- wall the thickest variation, where the thickness is 12.5 mm.

The thinnest version is needed to create interesting curved structures both under the ceiling and as a pier. Ceiling type is well suited for leveling the surface of the ceiling or creating an interesting design with lighting on top of the room.Wall type is appropriate for alignment of walls, and for interior partitions, which due to its thickness helps to achieve good sound insulation.

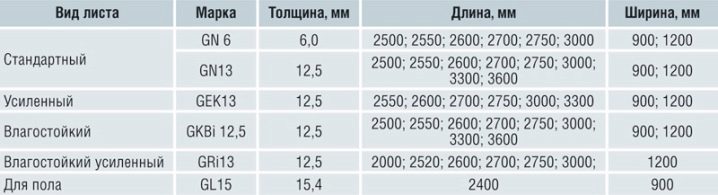

Standards

The size of the drywall can be different, which is convenient in case of large repairs or the removal of small surface irregularities. To be able to buy the required amount of material, there are standard dimensions of this material, where the width of the sheet is 1.2 m, and the length varies from two to three and a half meters. In addition to these characteristics, it is necessary to take into account the thickness of the GCR, which affects the total weight. Its fluctuations can be within 65 mm and reach up to 125 mm.

Differences in thickness are extremely important for ceiling structures, the lighter they are, the simpler they are to assemble and do not create the risk of breakage. In addition, less weight makes it possible to install fewer supports, which reduces the cost of repairs. Each sheet has a different cost: the thinner the cheaper, which makes it possible to save money if the design allows.

Due to the fact that various companies have begun to produce these products, and each is seeking to gain its authority, there are cases when the dimensions of sheets of GKLV do not coincide with the standard ones.

Length

Typical indicators of the length of a drywall sheet are:

- the minimum figure is 2 meters;

- the maximum option is 3.6 meters.

If we consider the production of Knauf, then here we can note the maximum figure of 4 meters. The difference between the size range of each option is 50 cm. The greater the height of the sheet, the stronger and thicker it should be, and, accordingly, heavier. Most often, the maximum dimensions are used in large spacious rooms for a large amount of work.. Thus, it turns out to increase the rate of repair, reduce waste and reduce the cost of material costs.

For experienced builders, it is easy to work with any dimensions of the product, and for beginners it is better to start with small sizes that are easier to measure, cut and make the necessary product. Long sheets are better suited for walls, ceiling and floor, and short for windows and low partitions.

Width

Plasterboard slab width is a standard unit, and is 1.2 meters. Whatever the length of the sheet, this parameter remains unchanged, and to increase the strength and prevent brittleness, only the thickness increases. If there is an urgent need to find a small sheet of GCR, then the firm Knauf will help here, because in their assortment there are products from 60 cm wideThat for some cases would be the best option.

Non-standard width will fit when it comes to repairing slopes on the windows, after replacing wooden products with plastic ones. In this case, it is necessary to close the hole that remained from the second frame and to make the wall surface smooth. But also small pieces of width suitable for the creation of various structures of plasterboard, which will have small dimensions.

It is much more convenient to work with such plates than with full-size ones, which means that anyone, even a beginner, can cope.

Thickness

Depending on the size of the drywall sheet in length and width, the thickness of the product also varies. This is due to the fact that the pressure on the material increases, and without proper reinforcement, the cardboard will not sustain, and the gypsum mass will destroy itself. For small dimensions GKL thickness will be 6.5 mm, for larger - 9.5 mm, and the largest figure is 12.5 mm. If a particularly complex object is being built, which should be as durable as possible, then you should use a slab with a thickness of 24 mm.

The choice of thickness depends on what will be made of the material. If this is a room partition without any functions,You can use thin and medium versions, if there is a shelf under the books in it, then the requirements grow, and it is better to take a medium or thick sheet of drywall.

For those cases when the surface of the gypsum will be affected by a constant and considerable weight, or there will be a valuable object on it like a television set, it is best to use the thickest type of plate.

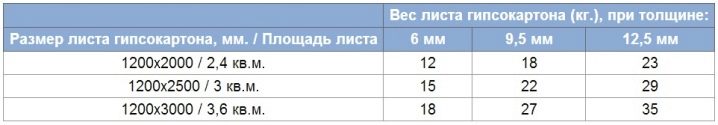

Weight

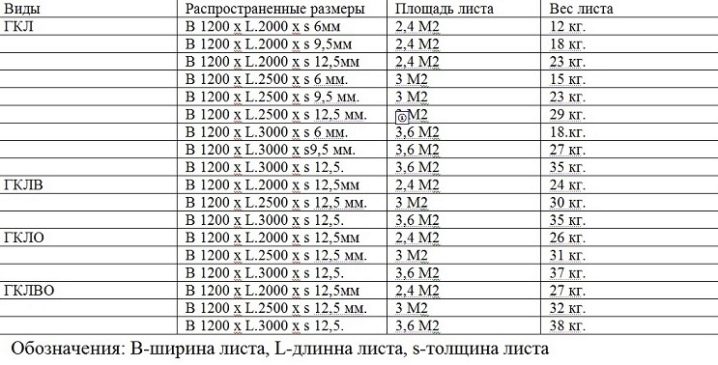

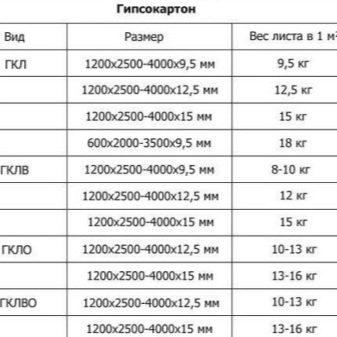

Depending on the length of the sheet, its width, and including the thickness, the weight of the sheet will also vary.

If the sheet is:

- 1200 to 2000 with a thickness of 6.5 mm, its weight will be 12 kg;

- 1200 to 2500 mm with the same thickness, weight will increase to 15 kg;

- 1200 to 3000 with a thickness of 6.5 mm, the sheet weighs 18 kg.

The weight varies in proportion to the thickness of the GCR slab, as follows:

- 1200 to 2000 with a thickness of 9.5 mm will weigh 18 kg;

- 1200 to 2500 by 9.5 mm will weigh 22 kg;

- 1200 to 3000 mm with the same thickness will weigh 27 kg.

If the first two options can be used on the surface of the wall and ceiling, then the third one is not suitable for suspended structures due to the significant weight of the sheet, since:

- 1200 to 2000 with a thickness of 12.5 mm; weight is 23 kg;

- 1200 to 2500 by 12.5 mm will weigh up to 27 kg;

- 1200 to 3000 mm with the same thickness will weigh 35 kg.

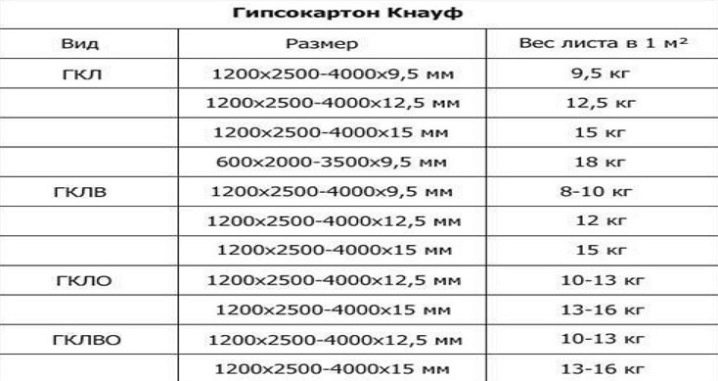

Knauf drywall has a greater number of product options both in length and thickness, in addition to the standard 6.5, 9.5 and 12.5 mm, there is also 15 mm.

The weight of the GCR sheet of this company will have the following indicators:

- 1200 to 2500 by 15 mm weighs 15 kg;

- GKLV with the same indicators will weigh the same;

- GKLO weight of the same dimensions will be from 13 to 16 kg;

- the same indicators will be at the sheet GKLVO.

Only having understood all the numbers and values, you can choose the appropriate version of the product and start working with it, otherwise it will be difficult to hope for an easy repair process and a good result.

What does the size depend on?

A standard sheet of drywall has only one stable indicator, and all others can vary depending on the scope of its use. To choose the right material you need to understand which type is suitable for what works.

There are such varieties GCR, as:

- arched sheets;

- reinforced;

- acoustic, with perforation;

- sheets with vinyl coating.

Acoustic plasterboard sheets are best used for large rooms by type of classrooms or halls, which should have an acoustic effect. If we consider vinyl sheets, then their undoubted advantage will be the readiness of the material for use, no treatment should be applied to the surface.The scope of its use is narrower due to the inability of the material to breathe.

As for the arched version, it is the most versatile, having a small thickness, so with its help you can create any composition.

If it comes to the wall type of product, it is necessary to exclude thin sheets, which in this case would be inappropriate. Only the use of 12 and 15 mm GCR will allow you to build a reliable and sturdy wall.

If it is necessary to cover the wall, then the ideal option is to serve a sheet of 9 mm, with which it will be convenient to carry out all the necessary manipulations.

Selecting options for future walls or walls in the bathroom: it is possible to use drywall for this room, with the help of a moisture resistant option, it will be possible to avoid wetting and delamination of the material.

Knowledge of the types of products and their sizes allows you to choose the right material for repair. If you need to trim the entire room, then the standard sheets will be the best choice. In the case when the walls in the room have a non-uniform height, it is more convenient to buy non-standard sheets that are two times smaller in size. For places that will have to withstand heavy loads, you should use the thickest type of products.

Planning the manufacture of an interior partition, it is best to apply the longest GCR, which can reach 4.8 m, which significantly speeds up the repair process and eliminates the purchase of excess materials.

If such partitions are radial, then it is desirable to use two sheets together at once to strengthen the structure.

For aesthetes, and those who seek to make something unusual and beautiful in the house, you will need a designer type GCR, also called an arch, because its thickness is only 5, 6, sometimes 6.5 mm, it can be bent easily. In order for such a product not to burst from the loads, there are two whole reinforcing layers in its composition.

If we talk about non-standard materials, it is worth remembering about the soundproof type from the company Knauf, which has increased hardness and, in addition to the standard thickness of 12.5 mm, there are also 10 and 15 mm options.

The choice of the thickness of the product is dictated by the location. Thin sheets are fixed on the ceiling so as not to overload the structure, medium and thick can be laid both on the walls and on the floor. To create original compositions, thin material is needed, for wet rooms it is moisture resistant, and in the case of contact with a strong heat source, fire-resistant drywall is required.

Only by choosing the right types and sizes for the product, you can optimally calculate the amount of materials for the work and make repairs with minimal loss of time and costs.

Overview of offers of different brands

When planning major repairs for which you will need drywall, you need to know how to choose it correctly, and most importantly, what brand of product to pay attention to. Due to the fact that the popularity of this finishing material is growing, there are more and more new brands in which you can easily get confused and make the wrong choice.

If we talk about the most popular company, it is the German manufacturer Knauf, which focused its products on the destination, which is reflected in the characteristics:

- ceiling version has a thickness of 9.5 mm;

- wall - 12.5 mm;

- for various designs of fancy shape - 6.5 mm.

The length standard is 2.5 meters, but there are other options, more and less of these indicators. The smallest sheet length is one and a half meters, and the largest - 4 meters. The width here also departs from generally accepted standards, the minimum is 60 cm, and the maximum is one and a half meters.The thinnest sheet is 6.5 mm, and the thickest one reaches 2.4 cm. All these indicators affect the weight of the product, which can vary from 13 to 35 kg.

Like any professional company, Knauf produces not only the standard version of the sheet, but also the one that is suitable for wet rooms, for the manufacture of structures in contact with fire, and mixed type.

Product quality has been tested over the years, this brand makes durable products that are lightweight, good flexibility, they are easy to cut and easy to grind.

If we talk about domestic representation, then the Volma brand, which has a lot of positive qualities, will be a clear leader here:

- ease of installation;

- material reliability;

- excellent strength performance;

- wear resistance;

- the presence of an edge that prevents crumbling of the sheet;

- reinforced bending structure HL;

- environmental friendliness;

- optimal price level.

If you compare with global brands, you can note the small nuances that go to the minus of this brand. For example, there are no marking lines on the sheets, a large weight of the drywall itself, and the surface has a slight waviness, which requires additional processing.

Another brand is LaFargewhich is widely represented in the world, and is rapidly increasing the number of points of sale of its goods. Thanks to a good turnover, the pricing policy of the company allows us not to overestimate the cost, making products available to almost everyone. A feature of this production is the manufacture of sheets with a rounded chamfer and edges, which are pasted over with the help of cardboard film. It is this innovation made it possible to make a perfectly smooth surface.

If we note the shortcomings, then we can only select a small size range, namely, only 2 species with a length of 2.5 and 3 meters. Sheet weight is small and usually does not exceed 9 kg. Despite the lightness, the material is very durable and allows you to well isolate sound and heat. A special series in the production are sheets, with which you can create arches and various curved structures.

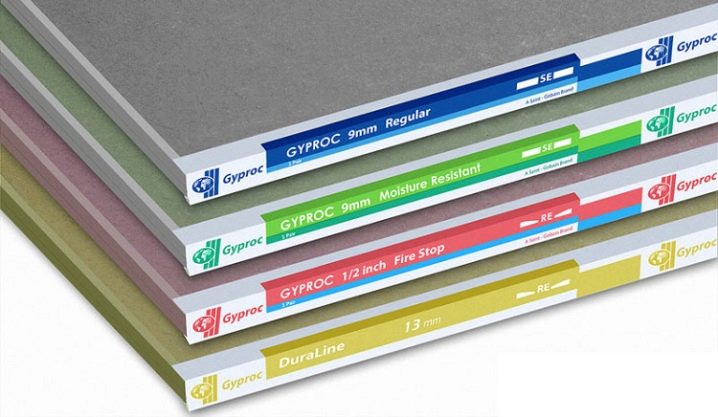

Another interesting company is Gyproc, which represent the Scandinavians. At the moment - it is a leading brand that has earned its popularity with environmentally friendly materials. Due to the special approach and choice of materials, the sheets are also lighter, which also became an advantage of Gyproc brand products.

Drywall from this company can be used indoors, for which versions of sheets from two and a half to three and a half meters in length, but with a standard width, are presented.

There are other brands that have their differences. Products company "Magma" represented on the market a variety of goods, among which there are drywall. Its quality is not bad, but it does not differ in any significant indicators. When selecting a brand, it is important to clearly understand exactly what characteristics the product should have in order to find the optimal solution.

If it is important to cover the maximum area with the minimum number of sheets, then it is better to choose Knauf, which will help in the case when small panels are needed.

There are times when products of lesser-known firms turned out to be high-quality and inexpensive, but often eminent counterparts far exceed cheap ones in quality, materials, environmental friendliness and other important indicators, so it is important to make the right choice.

How to make the right calculations?

In order to correctly calculate the required amount of drywall for repairs, the first step is to make all measurements of the repair zone, be it a wall, floor, or ceiling.The choice of sheets is carried out on the principle of selecting a larger length, so that it is possible to cut off the unnecessary part, rather than buying obviously smaller dimensions, then add the missing parts. Choosing the right size minimizes the number of stitches., what then will affect the duration of work on finishing, in addition, such a design will be more robust, and therefore reliable and durable.

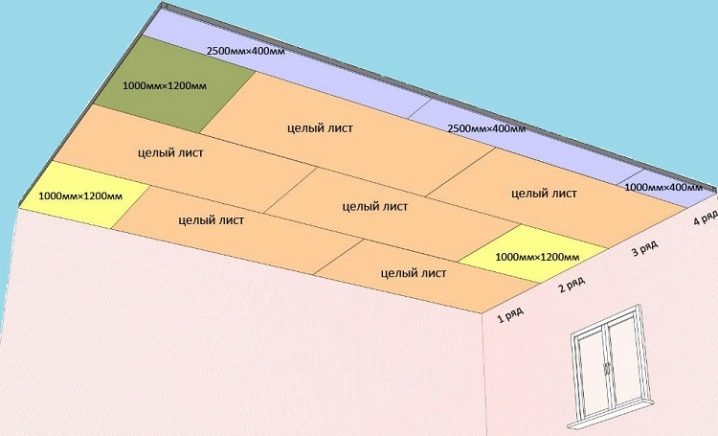

Professionals can easily calculate how many sheets and what dimensions are needed for a particular job, but for a beginner this is not an easy task. In the absence of experience, it is important to draw a map of the surface on which work with the GCR will be performed., and the cells clearly define the height and width of the sheet, and, accordingly, their number.

For those who do not like to deal with drawings, you can rely on the dimensions of the room, but to buy material with a margin of 10 or even 20%.

The same principle works for work with the ceiling. After careful measurements, it is necessary to purchase sheets of a suitable size, it is better they will be larger than the smaller one, so that you can cut off the excess, than add it. The smaller the seams on the ceiling, the more beautiful the surface will be and the easier it will be to work with.. In order to achieve this effect, it is important to correctly place the sheets, having data on the width and length of the repair site. If it is difficult to do this in your mind, you can also use a drawing in which you can try several layout options by choosing the most suitable one.

When choosing a drywall for a specific room, it is important to understand its specificity in order to choose the appropriate type and size for the optimal number of sheets that will be needed for repairs.

Having correctly calculated all the indicators, you can get a good and high-quality result.

Useful tips for all occasions

In the event that a home needs repair, for which drywall is required, it is important to choose it correctly, for which you should pay attention to important factors:

- Choosing a place to buy: market or hardware store. Products on the market can be stored in inappropriate conditions, which adversely affects the performance of the product. The store often has optimal storage conditions and certificates confirming the authenticity of products. Building supermarkets allow you to choose a product from a relatively large option of firms that differ in characteristics and price.

- Inspection of the place of purchase and warehouse. If it is important to get a high-quality repair, then it is worth wondering how exactly the materials that will be delivered for work are stored;

- Loading and unloading. If there is a possibility, it is worth staying near the movers at the time of loading and unloading sheets to see any irregularities in the process. This will help to avoid any damage to the drywall.

- Having received the goods, it is necessary to examine it well., sheets should be smooth, clean and uniform. The presence of chips, dents and scratches indicates poor quality, problems with storage or transportation.

It is best to return the damaged sheets back, otherwise their service life may be significantly reduced.

When drywall is bought for the first time, and for work you need a lot of sheets, you need to check the product of a particular company from a particular supplier. Only one sheet is bought and cut into strips. It is required to carefully examine the contents of each strip., to evaluate whether the composition is homogeneous or not, whether there are external differences.

If everything is in order, and there are no questions, you can safely order the required number of GCR from this party. But in case of doubt, it is better not to take risks, and look for another option.

Planning a home decoration, it is necessary to carefully check the composition of drywallbecause small firms that offer an affordable product can add harmful substances to their composition, they will emit toxic fumes or odors that negatively affect human health during operation. This is especially important for the repair of the children's room, where everything should be as natural and high-quality as possible.

Do not forget about the specifics of the premises: for shower, toilet and kitchen the best option is a moisture resistant plasterboard, and in ordinary rooms the standard version is suitable for dry living areas. Thin and light structures are used on the ceiling, and as thicker and durable as interior partitions.

The right choice of sheets of drywall will be the basis for a successful and beautiful repair in any room.

Tips for using and installing drywall are waiting for you in the next video.