How to bend drywall yourself?

At the moment, drywall has become the most used material for construction, in particular, for the manufacture of decorative elements, even in the most complex interior projects. You just need to know how to properly give it the desired shape.

Main application

The area where this material is applied is very wide. You can meet him in the decoration of almost every room. It is used to:

- alignment of wall and ceiling surfaces;

- manufacturing partitions between rooms;

- trim door openings;

- constructing levels of suspended ceilings.

pros

Plasterboard material has many positive qualities, namely:

- environmental friendliness;

- vapor permeability;

- flat and smooth surface;

- insulation properties of sound and heat;

- ease of use;

- sheet size allows you to work in a short time;

- low weight;

- possibility to cut out any elements from a sheet, and also to bend them in several ways.

Minuses

Just like all construction materials, gypsum board has not only advantages, but also disadvantages, such as:

- due to the moisture absorption properties of gypsum, it cannot be used in conditions of high humidity;

- fragility, due to which you have to handle it very carefully;

- on the walls of plasterboard is difficult to fix anything, additional accessories are required.

Application in design

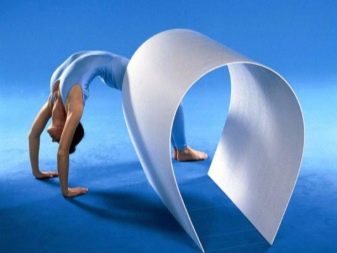

These fragile plates are often used to implement the most intricate ideas of interior design. This contributed to their property to take a variety of forms, including the curved type. The latter are used for different purposes.

- With the help of figured and curved shapes, acoustic and sound effects can be added to the room. This feature is often used in large halls: theater, office, entertainment centers and similar premises.

- It is very easy to hide various communications behind the curvilinear figures of the interior, without losing the picture of the overall appearance. In addition, gypsum is resistant to high temperatures, which makes it possible to safely conduct electrical cables under it.

- The curved shape of the panels expands the possibilities of the designer, with the result that he can bring to life his bold and original ideas on the interior design plan.

Ways of bending

Four ways of bending drywall sheets predominate.

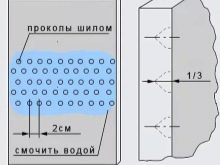

Roller

Application in the processing of the material of the needle roller. Such a simple method does not require much time and effort. With the help of a special tool, the plate is pierced from two sides, because of which it acquires a softer and more elastic quality.

For even more effect, the sheet can be moistened.

Knife

It is possible to bend drywall with a sharp knife, this method is suitable for plates of almost any thickness. To do this, cut through the thickness of the material in several places. How many slots need to be made depends on the radius of the desired bend. The steeper it is, the more and more often the part must be cut through. This method does not require moisture.

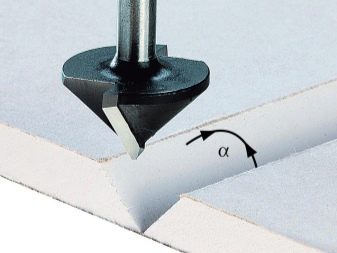

Milling cutter

When a construction with a very small radius is necessary, then bending is performed using a milling cutter. Cutter strips remove the thickness of the canvas, leaving about two millimeters.

Water

If the design involves a gentle contour, then it is sufficient to use a simple method of water soaking. One side of drywall moistened to a certain state. As soon as the material becomes pliable, it is placed on the template, fixed and dried.

It’s quite simple with your own hands at home to bend the GCR in a semi-circle. Such work can even beginner master.

Preparation for work

At the beginning of the preparatory work it is necessary to determine the bend radius. It is very important for the final result to coincide with the planned construction. Depending on the selected radius, the thickness of the material used in the work is selected. From a thin canvas you can make a steeper arc.

Optimal parts suitable for the manufacture of spherical structures are those whose thickness is 9.5 mm. But this does not mean that items with other sizes cannot be used. For these sheets, you need to choose the best method of bending.And also need to consider other parameters of the fragment.

The narrower the element, the easier it is to bend it. When using strips up to 200 mm wide, there are no problems. Such a detail can be simply fixed on the template and held for a certain time, this will be enough for the drywall to take the necessary shape.

Sheets of a wider size will have to be pre-treated with a special roller and liquid. After that, fix the fragment on the template, where it will take the desired shape under its weight. Within a few days, the part must be periodically fed with moisture. Due to the fact that the process is long, this method is rarely used, often preferring to use a milling cutter or knife.

Much also depends on the length of the bent element, because the short part is more difficult to bend than the long strip.

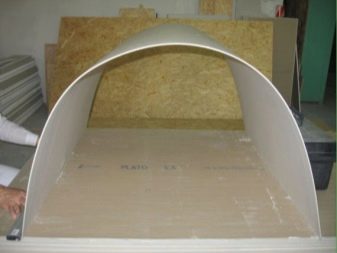

Template making

To give the plasterboard fragment the necessary shape, especially if this element is large, you must first make a pattern. Such a device can be made from a suitable material at hand, for example, from chipboard, plywood and the like. It is important that the selected raw material was about ten millimeters thick.

The template should have a radius, width and length slightly smaller than the same dimensions of the workpiece of the proposed design. The template is assembled from several parts: two sidewalls and spacer plates. The side parts define the radius, and the spacers provide the required width for the pattern. Having made the necessary parts, the device is assembled with the help of screws and wooden bars.

Required tools

To bend the drywall will need the following tools and tools:

- water tank, sponge (when the sheet is deformed by the wet method);

- special roller, cutter or knife;

- awl;

- roulette, ruler;

- putty knife;

- screwdriver or screwdriver.

Fold methods in domestic conditions

Dry bending

This method is rational to use in the case when it is necessary to obtain a flat product with a small angle of deformation. For this, it is recommended to use thin plates, 0.65 cm thick. If such a sheet is not available, sheets with a thickness of 0.9 cm can be used.

The order of work is divided into several operations.

- First you need to make a frame, which will be fixed drywall.

- Then prepare the blank of the desired size and, drawing it to the frame, fasten with screws. If necessary, you can gently press on the part, but be careful not to break the weak material.

- Fabrics with a thickness of 0.125 cm are suitable for products with a radius of more than 1,800 mm. It is recommended to bend such blanks only in heat and additionally to warm up during work.

- If you need to create a strong structure, you can make it of two layers, with the seams must overlap each other.

Using a special roller

The process of curving the web by this method is done through several actions.

- A layer of drywall is taken and laid on a stable plane. If you want to create a convex part, then a needle-like roller passes over the back surface of the sheet. If you want to make a concave shape, processed the front side of the workpiece.

- Wet sponge soaked with liquid treated surface. The fragment should be wetted for approximately one hour, but wetting of the back side of the part is not allowed. This must be prevented in order to avoid breaking the material.

- A wet blank is placed on the template so that its middle coincides with the center of the part. Slowly and gently bend the seam and clips are fixed at the ends. In this position, the product is left to dry. In a situation where several fragments are made, it is necessary to securely fold the folds of the web with scotch tape, then remove it from the template to work with the next element.

With the cutter

It is good to use a mill in a situation when it is necessary to make an element with the small radius of deformation. Such work is carried out in several stages.

- A blank is cut of the required size and configuration, located on a stable plane with the rear side up.

- A cutter parallel to the line of bending are selected grooves. Their depth and location in frequency and width are determined according to the radius that is planned as a result.

- Remove the dust from the work of the cutter from the part and lay the workpiece on the prepared template with the slots upwards. Fixing the curved element, you need to putty slots. Leave the fragment in this condition until the putty dries.

Metal profile bend

The metal profile is an integral part of the installation of drywall, as the gypsum cladding is attached directly to it. And in the case of using curved finishing structures, respectively, the frame on which drywall is mounted should also be of the appropriate configuration.

In order to bend the metal base, it is necessary to cut through the profile. When making a flat sphere, the slits must be made at equal distance and parallel to each other.

For other configurations, you can saw through, depending on the planned result.

One end of the cut profile must be fastened at the beginning of the intended construction. Further, the metal element of the frame can be bent in the desired direction and to the desired level.

Bending plasterboard elements in the domestic environment is a simple task that you can make yourself. To do this, you need to acquire the necessary materials and tools, as well as to choose the most accessible and rational method of work.

For details on using a needle roller to bend drywall, see below.