Drywall Dowels: Choice Features

Any repairs require reliable fasteners for building materials, regardless of the task. However, some products, such as drywall, need special tools that most effectively perform their functions. In particular, this concerns dowels for drywall. Such products are presented in the modern market of building materials in a wide range.

Special features

Today used a lot of different fasteners, manufactured to work with GCR. The presence of a huge range of such parts is due to the demand for drywall. It is widely used for the construction of arches and partitions, leveling walls and ceiling surfaces.And since the sheets of material are very fragile, one cannot do without special dowels when finishing the premises with this material.

In addition to the specificity of the building material itself, the details also have their own characteristics, on the basis of which they are given preference in a particular case. In addition, an important point is the technology of working with dowels, since the reliability of the entire structure being constructed directly depends on the correctness of the work done on their installation.

Quality dowels have the following features:

- they are treated with anti-corrosion compounds;

- for the production of such metal products only high-quality alloys are used;

- Combined products of the same type may differ in weight, which they can withstand, and sometimes in size;

- spacer components guarantee high-quality fixation of the product to the gypsum board.

A distinctive feature of all varieties of dowels is the harpoon principle of the device, thanks to which they perform their tasks.

In work it is necessary to use only the fastener, the sleeve of which will be as close as possible to the sheet.Also an important factor is the level of permissible load on the part. Based on this parameter, the size of the fastener is selected.

There are three main types of load:

- dynamic - dowels resistant to vibration are necessary;

- horizontal - in this case, the fundamental factor is the mass of the part, the assembly of which will be carried out;

- vertical - when fastening products, the length of the dowel will be important.

Types and sizes

Dowels are divided into different types based on a variety of factors. According to the technology of fastening parts can be divided into two groups:

- fixation is carried out by friction;

- the dowel is fixed according to its configuration.

Twist the product into the base in two ways - using end-to-end or pre-assembly. In the first case, you do not need to drill anything, the part goes into the material itself. This technology is in demand during the device facades. The latter method requires working with a drill. At the base it is necessary to drill a hole, then you need to install a product in it and fix it with a screw.

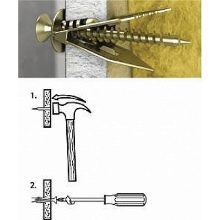

According to the type of installation, the following fasteners are distinguished:

- parts that need to be hammered into the surface with a hammer (driven parts are in great demand);

- screwed products (to fix them on the wall you need to use a gun).

In order to choose the right dowel for the gypsum board, you need to have an idea about the advantages and disadvantages of all types of such fasteners.

"Molly"

Dowel refers to the type of expensive products of high quality. The fastening of this element is carried out in a pre-made hole, whose diameter is 8 mm. The presence of a two-prong side helps to fix the dowel tightly in the drywall. This configuration eliminates the risk of scrolling an anchor in it.

Positive features of the dowel of this type:

- the detail perfectly maintains high loadings;

- in case of need the element is easily dismantled;

- screws are attached to the plug (included).

Driva

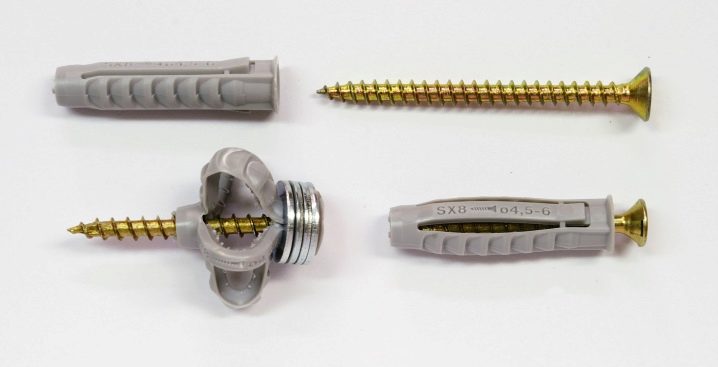

Dowel "snail" - a very popular product, which is made of metal and plastic. This type is purchased most often. The part is attached to the sheet as follows: a 6 mm hole is made, a dowel is inserted into it, and then it cuts into drywall using the same technology as a standard screw.After mounting the dowel, a screw of 3.5 or 4.5 mm is screwed in.

The installation technology of the fasteners of the drive is quite simple, however, when buying screws or screws, you should take into account the length of the dowel, which for plastic products is 23 mm. Metal products are available in lengths 33-44 mm.

Fischer PD

Another type of fasteners for gypsum boards. Its configuration includes a plastic base for the screw. During installation, it is firmly pressed against the joint with the material and securely fixed with a screw. This feature provides protection against falling out of the sheet.

Dowel nail

Designed for installation to concrete. The product consists of 3 nylon sections and a special hole at the end. High-quality fixation is achieved by bursting the walls simultaneously in several directions. Such dowels are recommended for use for end-to-end installations, for example, window or door constructions, baseboards, etc.

Steel products, fixed at the base with a pistol, are used for mounting structures with high weight.

Dowel screw

It is realized for double-layer or single-layer sheets, which are decorated with a decorative coating, as well as an insulating material.When purchasing such a product, you should pay special attention to the presented sizes, in order to exclude situations where an element that is too long protrudes from the casing.

If the sheet thickness is more than 15 mm, then to install the dowel, you will need to make holes for installation.

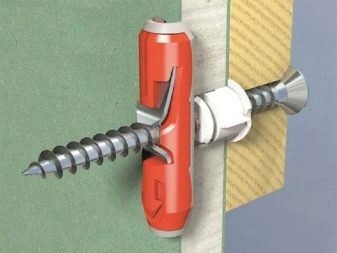

"Butterfly"

A part that has a drop-down expanding stop at the end, the presence of which allows the dowel to withstand quite serious loads. The fastening element requires a hole in the base. For fixing the product is supplemented with a special cuff. The dowel butterfly is used for material with a thickness of not more than 5 mm.

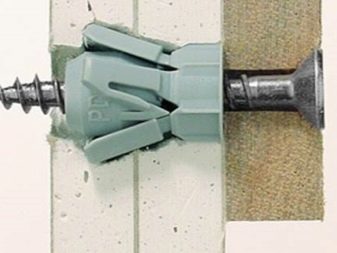

Dowel umbrella

This is a self-installing fastener that opens behind the slab, which provides high-quality fixation on the surface. Its installation involves drilling a hole. Most often, this type is used for ceiling surfaces of gypsum boards.

The dowel for drywall with a drill is installed by screwing it into the base. When mounting parts also it is necessary to follow its length.

This type of fastener is used for double drywall, where insulation is an important point.

Screw products are a set of expansion plugs and nails. Reliability of installation directly depends on compliance of the sizes of products for these or other tasks.

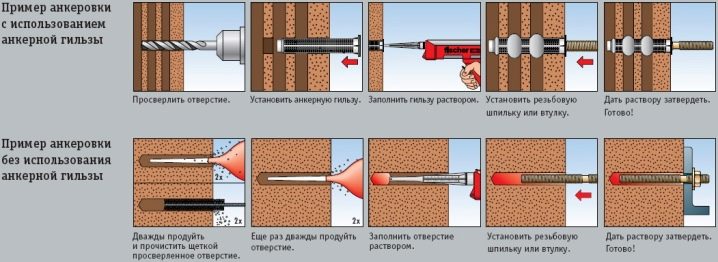

There are also chemical anchors. They are available in the form of a capsule with adhesive liquid and a sleeve.

An important nuance in the selection of the desired dowel for GCR is its size. Manufacturers of such fasteners offer products with the following diameters: 3; four; 4.5; five; 6; eight; 10 mm with a length of 12 to 260 mm.

Manufacturing materials

For the manufacture of dowels used different raw materials.

- Widely used metal, including aluminum products and stainless steel products. Metal parts are not deformed and have a good bearing force. For some works, brass and titanium fasteners are used, which are distinguished by their high cost.

- Used and plastic, including nylon, polyamide and polypropylene. The latter material has excellent wear resistance. Also dowels from this raw material can withstand temperatures of up to +140 C. Polyamide and nylon are vibration resistant. The disadvantages of such products include a ban on use at elevated levels of moisture.

- Dowels from polyethylene have the same properties as the raw material itself - resistance to acids and corrosion, the ability to use at low temperatures.

Accessories

For fixing the dowel a special bit-nozzle is needed, which facilitates the process of performance of work. Usually it is included in the kit.

Manufacturers

Among the manufacturers of dowels for drywall can be identified several of the most popular companies.

- Fischer PD and PDS (Germany) - products from rounded nylon. Products are designed for weight up to 15 kg.

- Knauf-hartmut - modern high-strength products that can withstand loads up to 50 kg. Dowels are made of metal and plastic elements.

- Walraven BIS GOLD - driven dowels, which independently open at the base.

In addition, products from China, Finland and Liechtenstein are on the construction market.

How to choose?

In order not to be mistaken with the choice of parts for fixing the gypsum board, it is necessary to take into account a number of nuances:

- the level of future load on the part;

- the need and possibility of dismantling;

- cost of production.

In each individual case, the list will be supplemented, since the process is most often associated with a mass of different moments.The most reliable is considered to be mounting in the bearing profiles of the structure. Based on this, it is better to pre-consider the presence of the profile where there will be fasteners.

Sometimes, in addition to dowels and screws, you need to purchase a nozzle and the screwdriver itself. Also worth remembering is the importance of personal protective equipment.

In the absence of gloves, you need to purchase them.

Application

Using electrical devices for screwing in dowels, you need to be very careful, as excessive force during installation can damage the drywall sheet. Drilling holes in the mode punch for work with gypsum boards is prohibited.

In the surfaces lined with tiles, a hole is made under the dowel in accordance with its size. In this case, it is better to stay on the dowel molly. To quickly mount, you can use the dowel driva. The advantage of this product is the fact that the material does not need to make any additional holes, which allows you to preserve the integrity of the structure.

The dowel-butterfly, as well as the molly, needs work on drilling a working hole.

There are a few simple guidelines for screwing dowels to drywall:

- First of all, it is worthwhile to designate what characteristics the drywall has to work with, and also to determine the weight of the attached product.

- It is also important to competently select a screw if it is not included in the standard equipment for the dowel, because the screw can damage the fasteners from the inside.

- The hole must be drilled a little more in diameter than the part itself. This feature of the work allows you to avoid cracking of the material during installation of the part.

- Holes must be thoroughly cleaned from crumbs and dust. To do this, you can use an ordinary home vacuum cleaner.

- The screwdriver, which is screwed in without a screwdriver, should not be scrolled at the end point of the installation. To do this, do not fix it in the base until it stops, leaving this job for the screwdriver with the appropriate setting.

- When the dowel-umbrella or fungus is already installed in its place, and the desired product is firmly located on the fastener, the hole formed in the sheet of drywall must be carefully masked with acrylic if it is small. In another situation, additional application of putty is required.A positive feature of acrylic is its rubberized base, due to which it is possible to significantly reduce the pressure level of fasteners on such a fragile material as drywall.

- The dowel-butterfly has a certain installation technology - you need to press the folding blades of the product and push it inside. Twist this dowel to the desired position can even ordinary screwdriver.

Plasterboard fasteners today are presented in a large variety. Therefore, the choice in favor of a product should be made based on the level of complexity of the design that needs to be attached, its functional tasks and installation techniques, taking into account the cost of the products.

You can learn how to do a drywall installation with your own hands by looking at the video below.