Drywall: features and scope

Plasterboard sheets have long been among the actively used materials, and they are known to the same extent as brick, glass or concrete. But even such a well-known finishing tool is surrounded by a large number of myths that confuse consumers and misinform them. It is necessary to clearly understand what this material actually represents, where and how it should be used and with what tools.

Special features

The word "drywall" itself indicates a combination of compressed gypsum, surrounded by an outer sheath of thick paper. Anyone who has seen GCR, does not doubt its perfect evenness. This design is able to transfer a fairly powerful load and at the same time allows you to work without unnecessary problems. In addition to a pair of basic substances, components are used to ensure the gluing of the sheet, as well as foam additives for gypsum.

The role of cardboard is twofold - it not only reinforces the block from the outside, but also acts as an excellent base for:

- putting decorative plasters;

- gluing wallpaper;

- dyeing with almost all types of paints and varnishes;

- other types of interior decoration.

GKLA - this is a kind of drywall, which is designed to improve the acoustic properties of the room, this is directly indicated by its decoding. Similar sheets can be used for:

- frame partition;

- wall cladding;

- false ceiling formations;

- finish coating panels ZIPPS.

Before using GKLA, it is required to maintain for 24-48 hours at the same temperature at which the installation will be carried out. Safety standards are standard. Store the product folded into pallets in a room with dry and normal humidity.

The stack outside the warehouse cannot be higher than 5 m; otherwise, its stability and the stability of the material properties cannot be guaranteed.

Improving the acoustic properties is achieved by perforation and covering the back edge of the sheet with a non-woven cloth. In the through holes, the sound waves do not leave the air from the surface, but remain inside and are held in a kind of “trap”. The sound quickly goes out.Due to this property, acoustic drywall is used in recording studios and in other rooms where protection from extraneous noise and echo is very important.

Rare cinema hall, conference room do without such material. Perforated drywall almost does not interfere with the penetration of sound waves from one room to another, so it can only be used in conjunction with other solutions.

It should be noted that the outer shell of the GCLA cannot be finished additionally, because it will worsen its characteristics.

Installation of such structures does not differ from the installation of an ordinary gypsum board. The difference between the modifications is determined primarily by how exactly the perforation is located, what is the shape of the holes. With both solid and perforated holes distributed over the blocks, the perforation can be round (8 mm), square (12 mm) and absently round (0.8, 1.5 or 2 cm). The edges are divided into curly (stepped) and straight.

Advantages and disadvantages

Knowing the composition of drywall, you can confidently say that it is not harmful to health and that the environmental friendliness of the material meets the highest requirements.The outer surface is perfectly smooth, the material is not prone to fire. To handle it is quite simple, and the cost of creating structures is relatively small. A very important property - drywall is initially ready for installation and use. But do not assume that the GCR has only one positive side.

Serious restrictions on the use of such elements impose their tendency to get wet and destroy under the action of excess moisture. It is impossible to apply them in outdoor work and in the decoration of the facade of the building. And even in the bathroom, kitchen and toilet it is permissible to use not all types of material. The surface easily crumbles when nails are hammered into it, screws are screwed (bolts), other fasteners are installed. The fastener will instantly fall out as soon as they try to hang something heavy on it.

Kinds

What is a perforated noise insulation drywall, already in general is clear. But on the market there are a number of other options for such products, which differ in their characteristics. Laminated material is made on the basis of ordinary sheets, covering them with vinyl film. You can find various commercial designations of such structures:

- acrylic GCR;

- LGL;

- gypsum vinyl;

- vinyl or colored drywall.

The surface can have the most impressive decorative properties, the differences are manifested in a specific color, pattern and texture. Modern technology allows you to play almost all existing natural materials. The base can also be any: it does not matter whether the sheets are attached to a tree or a metal surface, to concrete or to a brick.

The outer shell allows you to gently wash the sheets, they will not absorb dirt. Due to lamination, the resistance to sunlight, high humidity and significant heat increase.

Ordinary wall sheets are painted gray and marking is blue. The width of such products is standardized (120 cm), as is their thickness (1.25 cm). But the length varies between 230 and 250 cm. The units mounted on the ceiling are always thinner - only 0.95 cm. But both options are too susceptible to ingress of water.

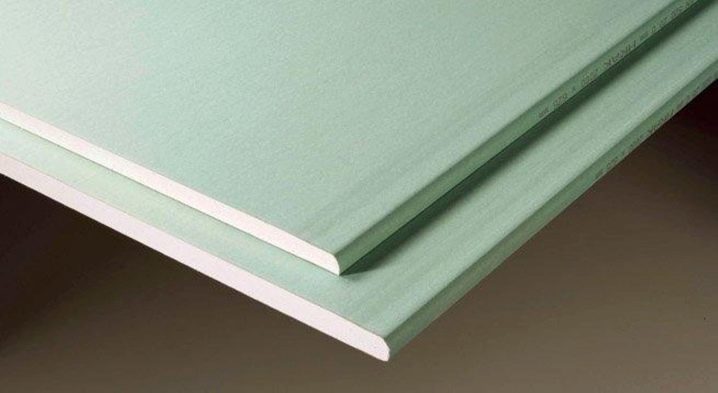

Moisture resistant variety (GKLV) is available in two formats - the same 2.3 and 2.5 m with a width of 1200 and a thickness of 12.5 mm.The color is green, blue ink is used for markings. Special impregnation is used to process both the middle part and the cardboard shell. Used drugs have the property to suppress the development of microscopic fungi. Sometimes a different type of additive may be included in the GKLV.

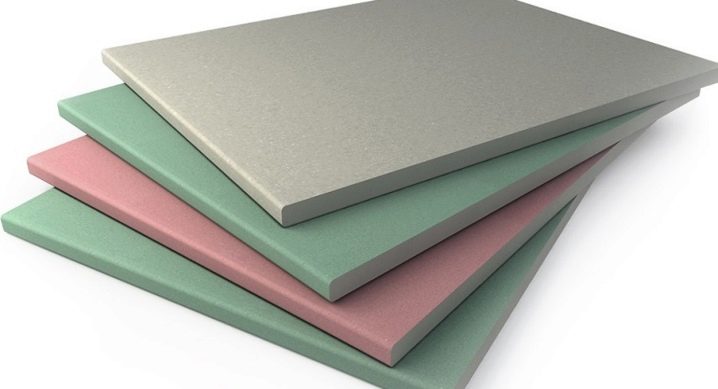

Hard-igniting drywall is sold under the designation GKLO. In the production of such material is painted in pink or light gray scale, for applying any inscriptions apply red paint. It is easy to make a chimney lining from GKLO, but it is worth taking it when the fireplace is surrounded from the outside. The central part always contains an increased concentration of fibers and reinforcing elements.

If the room is both wet and flammable (for example, a boiler room), it is worth taking a GKLVO, which combines hydrophobic and anti-fire properties.

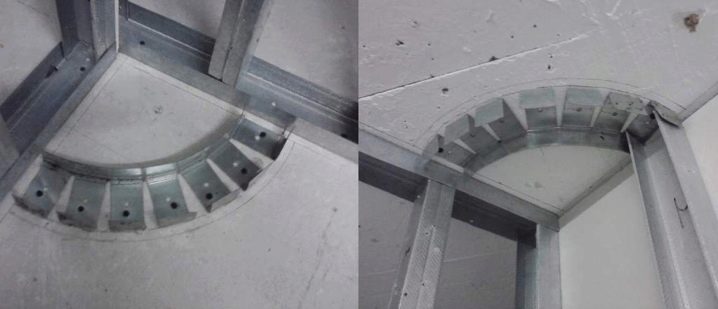

The combination of moisture-proof and fire-resistant qualities is demonstrated by the green coloring of the material itself. The inscriptions on it are made only in red. The last type worth considering is flexible drywall (some manufacturers and sellers call it arched).Sheet thickness is very small - only 0.65 cm, which is why it is almost always necessary to mount the coating in two layers. Hardening of the core with glass fiber threads helps to form curved contours of the most different radius.

Criterias of choice

Characteristics of drywall may be somewhat different if you want to use them in special conditions. It is not difficult to buy stuff:

- actively absorbing sound;

- adapted for external mounting (with additional wind protection);

- with the increased heat conductivity (it is optimum for a heat-insulated floor and in some other cases);

- with maximum thermal insulation;

- with a mass of layers that inhibit the ingress of moisture and having foamy properties;

- a restraining flux of electromagnetic radiation, including X-ray.

The most unusual gypsum boards are equipped with a center of cement, and the cardboard in them is covered with reinforcing fiberglass. Such a solution is precisely intended for the front facade decoration of buildings. The latest development of gypsum board is gypsum fiber. In its composition cellulose is added to gypsum.Due to the special flatness and mechanical strength, there is no need to apply a primer before final finishing.

Such products (GVL) should be used during the installation of the floor, as well as in the construction of a frame house. Since they are not threatened with moisture, there are no problems with the work on the facade of the building.

But in most cases it is necessary to choose less complex types of drywall. The simplest wall option is quietly and harmoniously installed in dry rooms. Where fire is burning or significant heating occurs, it is much more correct to use fire-resistant structures. Important: do not confuse it with the usual heat-resistant, which only stably maintains its qualities at high temperatures.

Restoration drywall is used to create cladding on old structures and to simulate wood (flexibility allows you to make it curly parts).

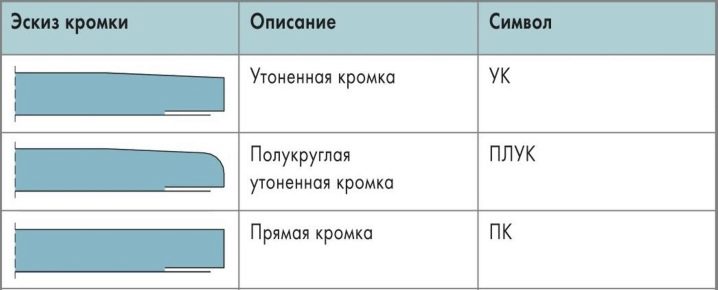

Data sheets are made in the shape of a rectangle, and the most practical height is 300 cm (since it is desirable to sheathe the entire surface of the wall in one block without joints). When choosing, you need to pay attention to the type of edge: if it is straight, there is no need to set the joints - this solution is ideal for multi-layered plating and for the inner layers.

The thinned edge is needed under pasting with reinforcing tapes and further application of putty; a rounded edge is similar in properties, but reinforcement is no longer required. The semicircular edge does not need a reinforcing tape, but if it is thinner (PLUK), on the contrary, it needs it. In these two cases, putty is necessarily applied to the surface.

Even the release of goods under a well-known brand does not guarantee 100% neither from a manufacturing defect, nor from a fake. Moreover, on the way from the shop to the warehouse, the drywall can also deteriorate, especially if you are careless in handling and violating the rules for working with it. Therefore, any responsible buyer:

- applies only to large shopping centers or specialty stores;

- does not take drywall, which is stored in conditions of high humidity;

- supervises the work of loaders so that everything goes neatly;

- inspects each sheet received upon ordering and after delivery.

When the corners are dented, and the drywall itself is uneven, when the paper lags behind it, and the plaster spills out or the geometry is broken - this is 100% poor quality or damaged material. When ordering the services of the repair team you should not trust her to buy drywall, it is better to control everything yourself. Defective products are recognized by a curved thin edge or a curved cut of the edge of the plate.

Delivery of drywall should be made on a specially equipped transport, preferably with a closed body or awning. Those firms that are not able to provide such a supply are not credible.

Scope of application

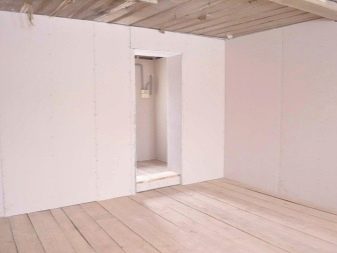

But here drywall selected and brought. Now you need to apply it correctly in a particular room. With this material you can achieve:

- alignment and update the appearance of the walls;

- the formation of interior partitions, mounted on a steel or wooden frame;

- arrangement of secondary walls (without bearing function);

- create a decorative podium;

- ceiling cover in one or several layers;

- receiving decorative items.

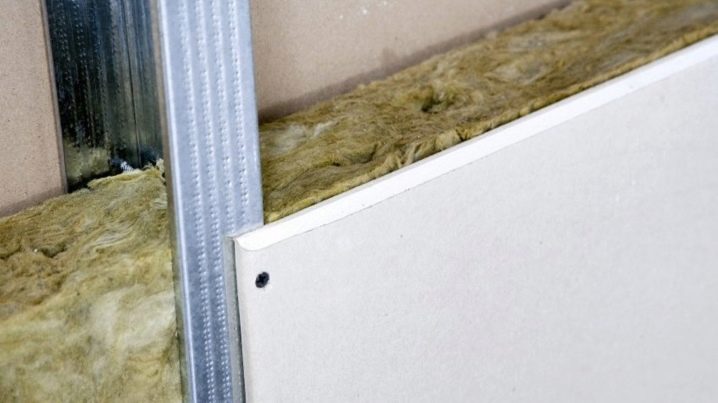

If you put the vertical bars in a zigzag manner, so that they do not touch both outer sheets at once and fill in the gaps with wadded materials, you can increase the sound insulation. Some people doubt whether it is possible to apply drywall to the bathroom.

Even finishers can refuse to use tiles or other heavy decorative elements on it. It is advisable to coordinate with them and the fastening of the material, and the execution of waterproofing. Moreover, both of these points are also fully consistent with the interests of the tenants.

Fixing panels directly to the wall is possible if the walls have only minor deformations. On top of the panels installed in this way, building paint is usually applied or wallpaper is glued. But when using any type of tile to mount the frame will have to be sure. It is made strictly from aluminum profiles, because wooden slats, even soaked according to the rules, are unacceptable in such work.

It will be logical to increase the strength of the frame when increasing the severity of the finish, this moment is required to be thought out in advance.

When working in the toilet, amateurs and professionals should follow roughly the same rules. Cutting sheets is sure to be consistent with the layout of the plumbing, furniture and pipe outlets - it is better to cut out the holes you need than to punch them additionally after a while.

Drywall is also used to decorate walls in a wooden house - here its key role is the same, that is, masking visual irregularities.

In addition to this purely utilitarian approach, you can take more drastic measures:

- put a partition between the rooms or in one of them;

- make an arch for visual differentiation of functional areas;

- prepare a niche.

The approach in these works is not too different from the actions in a brick, aerated concrete or solid concrete dwelling. In a room where they work with drywall, the temperature must be maintained at least minus 10 degrees. Otherwise, the quality and durability of the material no one can guarantee.

If the room is very small in any plane or in all three at once, it is better to consider other options for correcting defects that will absorb less useful space. When the wooden house is just put into operation, they wait 6 months and only after that they decorate its walls.

The timber is thoroughly prepared: there should be no gaps, it is necessary to carry out insulation. If the walls are made of logs, they are polished for the most dense junction.The frame is necessarily made floating, because the wooden buildings will still settle even after the end of regular shrinkage. Only aluminum or bars of at least 7.5x2.5 cm can be used as a support. The crossbars are made of 5x2.5 cm slats.

It is necessary to attach drywall to wooden supports using plastic dowels. It is unacceptable to glue the material directly to the wall (this technology solution is practiced only on concrete or brick). You should not give in to the impression of a visually flat wall, in fact, it is still rather rough.

Professionals recommend fitting the edges of all sheets to the central parts of the rails (both vertical and horizontal). A typical gap between screws or screws is 1.5 cm.

Its features has laying drywall on the floor. Concerns about this are due to the fact that the material was originally created as a wall-mounted, not transferring significant loads. But with the proper use of high-quality coverage no problems will arise. The first step is the maximum leveling of the base (it is desirable to do not only the screed, but also the filling with perlite, expanded clay, sand). The best option, according to most repairmen, is perlite.

The base is laid on top of a plastic wrap folded in half or more. Then there is a vapor barrier that will not allow wet the bedding. The overlap under the edges of the sheets is at a minimum of 20 cm. On top of the wooden base, it is not polyethylene, but ruberoid or bitumen paper that is laid. Both of these materials can be replaced with professional waterproofing, but usually this is done by qualified builders, for amateur repairmen it is too difficult.

Using drywall to level the floor with the subsequent laying of tile or laminate is a very practical solution. Among the varieties of material, it is recommended to use gypsum fiber sheet, it best meets the requirements.

When calculating the need for drywall, you need to assume that about 10% of it will go into marriage. Most likely, this figure will be less, but it is more correct to be safe and avoid exhausting the structures in the process of work.

If it is known that a tile will be laid on top, polyethylene is pressed by lags, then it will not arbitrarily migrate across the entire floor.

Bulk materials are placed in such quantity that their layer is on the same level with lags. Leveling is done from the windows to the entrance doors, and not vice versa. The second and subsequent layers are then placed in the opposite direction.

It is allowed to glue a tile from above only on the first-class, well proved in business of a type of glue. With sufficient funds, you can safely opt for liquid nails, and the use of cement will be an economical and relatively high-quality option.

To decorate the hallway in the apartment using drywall is not at all more difficult than laying it on the floor. Often there ceilings are made from this material. In small entrance rooms, a single-tier structure is usually installed, complemented by ceiling plinths and decorated with polystyrene foam. Carefully selected lighting devices that should create a feeling of great height of the walls.

The front trim of such ceilings is possible using:

- paints (water-emulsion and acrylic firmly hold the lead);

- wallpaper (non-woven or fiberglass based);

- decorative plasters.

When bends with many levels are formed from drywall, they should be painted white or pastel shade.

Experienced designers can advise and other colors, but in any case, it will be monotonous, without extraneous inclusions. This is the fundamental law of design work: either expressive form or bright tonalities.

The ceiling, even if it has only one “floor”, is painted in no more than three colors. Neon lamps create an attractive view of the upper part, regardless of its chosen color and the style of the entire corridor.

Tools for work

It is absolutely clear that the practical and design possibilities that GCR gives are almost unlimited, and it is difficult to find more versatile material. But you need to work with him, using the appropriate tools. Distances are traditionally measured using a tape measure (from 5 m), and evenness of lines is calibrated using plumb lines and building levels.

It is not recommended to use a marker for marking: it will remain and will spoil the view. It is much more correct to take a pencil or a special cord.

A simple stationery knife will help to cut the sheets properly.But if you need to do a lot of work, it is impractical because it leads to rapid fatigue. Not without reason, each qualified team brings with it to the object specialized knives for cutting plasterboard sheets. Choosing a knife, you should give preference to products with a rubberized handle - they are less dangerous in terms of injury.

Figured knots and other fine work make hacksaws on drywall, they also help out if you need to cut through the material in a place difficult for others to use.

A rare wall in modern homes does not have sockets and switches, and therefore special crowns are faithful companions to repairmen. It’s better to have a whole bunch of these important tools with you. It is recommended to stock up and crowns for metal, which will help out when you need to drill a profile or other hard object.

To form the necessary perforation and bend the sheets will be able to high-quality needle roller.

It is advisable to punch holes with a screwdriver. Wireless devices are more practical and more convenient than those connected to the electrical network through a cable, and in addition they are safer (there are no wires stretched in different directions).Evaluating the screwdriver, pay attention to its mass, because you need to hold the tool in your hand for more than one hour during the day. The cassette screwdriver is intended primarily for professionals, since it is more powerful and heavier than the domestic version.

If you know in advance that you have to mount the mass of the profile to a concrete base, you should take a gas construction gun. The Bulgarian is the omnipresent companion of any repair, it is extremely rare to need to work with profiles for the GCR. Jigsaw with an electric motor justifies itself, if necessary, to form a complex incision. But a direct cut of the material is much more correct to do with a hand saw, it gives much less dust. Precise profile cutting is achieved with metal shears (at least 2 pieces are needed - with a long, straightened and with a short curved shape of the cutter).

How to use your own hands?

A qualified master, mounting drywall on the wall or ceiling, be sure to putty the seams between the sheets. When they are filled, a reinforcing mesh (glass fiber) is put, then the surface is re-treated with a putty. When repairing it is essential to ensure the stability of the temperature and humidity in the room: not only during the work, but also within 48 hours before and after the closure of the seam.

It is necessary to work carefully, falling sheets, hitting them, dragging on the floor and so on are unacceptable. Even resistant to fire and moisture varieties should be protected from the "tests" of this kind before installation.

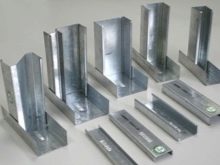

Most often, plasterboard sheets attached to the walls using profiles. The rack-type profile (similar to the letter C) is needed for partitions and for lining. Using guide profiles, the builders make the same partitions or are engaged in facial decoration of the walls. Ceiling profile structures are also divided into conventional and guides (the first subspecies helps to fix suspended ceilings).

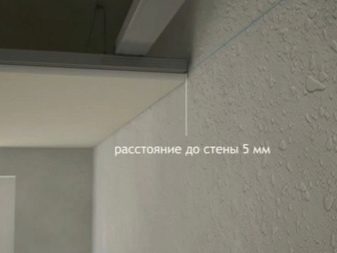

The first step is naturally marking on the walls. Further note how big will be the indentation from the processed wall to the outer line of the sheet. Most often they are guided by the size of 20 cm, which is enough for:

- surface leveling;

- accommodating virtually any electrical wiring;

- provide additional insulation;

- switch connections.

The same indentation in any case is made around the perimeter, including the floor.On the walls, the markings of the verticals are done with a gap of 60 cm, and the mounting points of the suspensions are best done in 50 cm increments (they are distributed in a staggered manner). When the wall has openings for a door or window, there should be at least 300 mm from the borders of these openings to the joints between the sheets. Having marked everything properly, they begin to set up a profile. First of all, it is placed along the perimeter of the walls being processed, and only then it is taken up to install hangers on which the guides are attached.

To attach the profiles and additional details you need to use dowels and screws. If the professionals work, they stick a rubber band on the profiles to make the construction better absorb noise.

Then comes the turn of the insulating layer - if possible, before fixing the sheet, the gaps between all the profiles are filled with foam plastic or mineral wool slabs.

But on top of them you can not immediately put sheets of drywall, they must be cut in accordance with the markup. Additional training consists in forming holes for sockets or switches; for this purpose, use hand-held saws or an electric jigsaw.

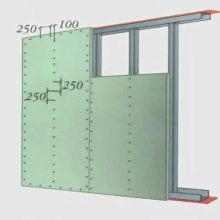

Attaching sheets is carried out on metal screws, the allowable pitch is 250 mm or less. It is advisable to embed the screws inside the gypsum at 0.1-0.2 cm. The laid sheets are putty, it will help close the joints and ensure the density of attaching reinforcing nets, a protective corner. At each outer corner such guarding elements are always placed, and whether to fix them on the inside corners, each builder decides for himself. Qualitatively applied putty does not allow visually detect reinforcing parts and fasteners.

Additional finishing works are almost always done, because they significantly improve the aesthetic and practical qualities of the premises. Most often formed niches and shelves that can become a substitute for large furniture. All plans are displayed on the schemes and in the marking applied to the walls.

It is extremely important to distinguish the sides of the sheet, since not each of them can be used as a face. No manufacturer writes this directly, but it is still possible to figure it out. The downside is always the one that is covered with inscriptions. It is possible and not to look narrowly, after all, with a simple material, the front surface is always white, with water-resistant green, and with a difficult-to-light pink one.

In some cases, gypsum plasterboards are used not only as a means of leveling the planes and improving their appearance, but also as a heater. Nothing strange: the level of thermal conductivity of drywall is ten times more perfect than reinforced concrete. Rolled blocks placed from the inside are held on the rough surface of the wall with glue or special umbrella dowels. Be sure to put the membrane that inhibits the movement of water vapor.

It is necessary to be careful of warming by gypsum plasterboards of unheated rooms. Even highly skilled performers rarely agree to such work, because they know about the many pitfalls with which it is accompanied. With significant jerks of temperature and humidity, even a first-class waterproof GCR will not stand. An exception is made for glazed balconies and loggias, with the minimum level - two-chamber double-glazed windows.

There is another question that is often asked by homeowners and novice builders, and it concerns the connection of gypsum plasterboard to the installation foam.

This solution is used relatively rarely, but it has its advantages, in particular,a significant improvement in noise protection and thermal qualities of the wall. In this case, the adhesion is fully secured, and the resistance to separation is very large.

Builders have a choice of different methods of fixing foam. In one case, it is blown into the technological holes, and the main attachment is made with dowels or self-tapping screws. In another, the surface of the sheet is covered with foam and then pressed against the wall. Repairmen in this case lose in the laboriousness of leveling, but can control the spread of glue.

In the first method, the sheet will need to drill, evenly distributing from 9 to 12 input channels. Having marked them on the wall, they are already drilling it and preparing passages for plastic plugs.

Manufacturers

No matter how thoughtful the design was, no matter how carefully the builders approached the work, they would not be able to achieve an optimal result using low-quality drywall. Therefore, it is necessary to focus only on those brands that for a long time fully confirmed their merits. In the first place, Knauf is consistently in demand.

In its lines there is a GCR for almost any work:

- on the walls;

- by floor;

- on the ceiling;

- to create complex geometric designs.

In the assortment, besides the usual one, there are both moisture-proof and resisting open fire material.

Among the Russian manufacturers, Volma is the leader in the rankings. Its products are invariably equipped with edges that effectively prevent the crumbling of the finishing material. The strength and reliability of the structures created is confirmed by the experience of a huge number of people. But keep in mind that the sheets created by Volma are heavy and do not have special marking.

The Scandinavian quality is as authoritative as the German one. A clear confirmation of this is Gyproc drywall. The company pays great attention to the environmental safety of products. She managed to ease the sheet by 20% compared with products of leading competitors.

The supplied material is suitable only for interior decoration, and the greatest length of the block reaches 360 cm.

If you need to buy GCR, which embodied the latest developments of the industry, you should pay attention to the offers from LaFarge. Many of its products are on the market, many of them first began to leave it with the French conveyors.

Tips

Impeccable material from a reputable manufacturer, caught in the hands of trained people - 95% success in installing drywall. The remaining 5% comes from tool selection and some technological secrets that you need to know thoroughly. So, joining GKL to a brick has a number of subtleties, ignorance of which can lead to sad consequences. So, the use of glue in this case is permissible if:

- trimmed area is small;

- the size of the relief of the material does not exceed 5 cm;

- you need to level the ceiling and not lose height in the room.

Experienced craftsmen will make sure that the drywall has reliable temporary supports before the glue sets. For this purpose, dowel screws are used, driven into the wall with a pitch of 0.6 m. As adhesives, along with specially designed compositions of industrial production, you can use foam and gypsum plaster (basic or finishing - does not matter).

Also replacing the proprietary mixtures can serve as glue for joining tiles, “liquid nails” and even silicone-based sealants. If you already have enough of these materials, you don’t need to buy anything extra.

To ensure the highest adhesion regardless of the method of gluing, it is recommended to thoroughly wash and degrease the brick. As a primer, the composition of cellular concrete shows the best results.

Along with the coating of brick and wooden walls, many people are interested in the question of whether a column can be made by gypsum plasterboard. Those who know the characteristics of this material will answer in the affirmative. But again, technological subtleties and nuances appear.

It is not necessary to create the entire structure from plasterboard - where decoration with this material is more reliable is the surface of a real concrete column. But if, nevertheless, it is decided to build a decorative element made of drywall, this should not cause any difficulties. The first step is to mark with pencils or markers on the ceiling of the outer contour of the future structure.

The created lines are transferred to the floor, and the construction level or plumb will help avoid the occurrence of distortions. The profiles, cut to exact dimensions, are screwed first to the floor, and then to the ceiling.

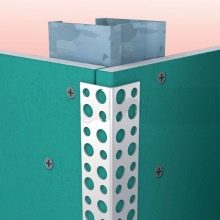

For the column, which is placed close to the wall, it is envisaged by the technology of a pair of vertical posts,equal to the height of the room. But when it is planned to decorate the center of the room, there are already four such elements. The reinforcement of the structure is provided by adding additional guide profiles every 0.5-0.6 m. Having attached the cut sheets to the frame, they are puttied and made out in accordance with the plan. Perforated corners will help to give the corners evenness.

Not always, with the help of drywall, they strive to emphasize some element - in many cases it is designed to close something that spoils the elegant appearance of the room, for example, a battery or pipes.

For your information: total cover is unacceptable, because then the heating efficiency will drop dramatically, and in case of a pipeline breakthrough, you will have to spend time destroying the finish to get to it.

It is necessary to provide either places for the exit of warm air or viewing windows (depending on what is being masked). Wall-mounted radiators surround the external duct, and the floor can be fenced off with a whole wall.

In any case, be sure to remove the old coating from the trimmed surface, remove from there all the dust and dirt, thoroughly primed it.When the wall is very uneven, it is required to correct it with the help of gypsum plasters, after which putty will certainly be applied.

You will learn more about the installation of drywall by watching the following video.