Acoustic Drywall: Properties and Applications

Currently, many people choose to finish their homes drywall (GCR). Today in the market of building materials you can find a variety of types of this material. The article deals with acoustic plasterboard constructions.

Special features

Acoustic drywall is becoming increasingly popular among consumers. Such a finishing material, unlike other types of similar panels, boasts excellent soundproofing properties. If you chose these gypsum plasterboards for repair, then you will not have to use special additional elements for sound insulation (mineral wool, glass wool).

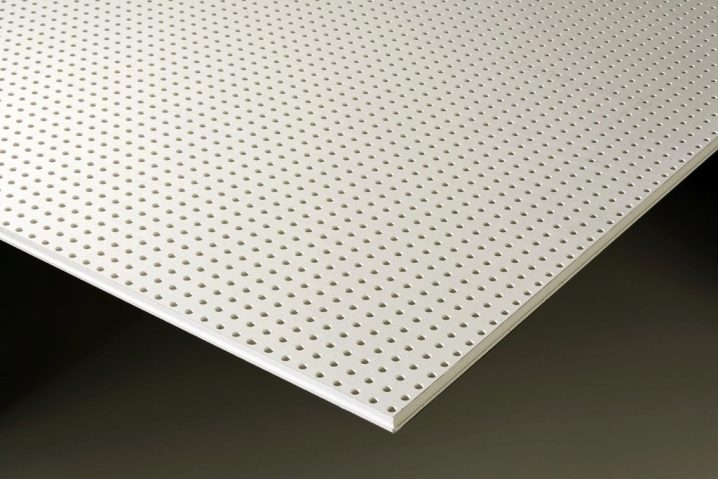

The sound insulation of drywall is ensured by using special perforated holes in the product. After all, they contribute to the complete absorption of sounds.The back side of such drywall sheets is made of nonwoven fabric. This material is already directly responsible for the soundproofing mechanism.

It should be noted separately that the perforation for such building materials can be very different in the type of hole placement. The most popular are two types of perforations.

- Block. The holes are located on the surface in small groups.

- Solid. The uniform arrangement of holes over the entire surface of the coating is characteristic.

It should also be noted that the perforation can be of different shapes.

- Round. The diameter of each hole is taken, usually 8 mm.

- Diffuse - round. Holes of various diameters (8, 15, 20 mm) are provided on the surface. In this case, they should be placed in a chaotic manner.

- Square On the material are square openings. Most often, their side is 12-15 mm.

Due to its noise-insulating characteristics, gypsum acoustic panels can be used in theaters, concert halls, recording studios, and cinemas.

Some experts recommend to finish with such material and ordinary living rooms in the house. This will help to save the owners from unnecessary noise from neighboring homes.

Kinds

Today, in the building materials market, consumers can come across various types of acoustic drywall. It has the highest noise insulation index in comparison with other types of such structures. Each individual type is distinguished by its special properties and dimensions. Therefore, when choosing a suitable version of plasterboard construction, be sure to pay attention to similar sheet characteristics.

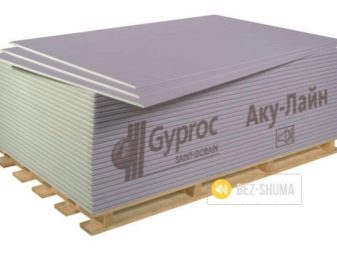

One of the most popular types of acoustic gypsum board is Gyproc Aku-line. Most often, such a building material is used in the construction of frame partitions. But many people use it for finishing cladding panels. Such plasterboard sheets of gypsum and special mineral fibers are composed.

According to many experts and buyers, the Gyproc Aku-line acoustic drywall is quite durable, reliable and vapor permeable. These products are made from completely recycled, safe materials, which makes them environmentally friendly. Standard sizes for these sheets of plasterboard are 2500x1200x12.5 mm. But it is worth noting that the length of the panels can vary considerably and even reach 3 thousand mm.

Another type of acoustic plasterboard material is Rigiton. Such designs are perforated large-format sheets. They are mounted with the help of a special putty using a special seamless technology. Most often, this drywall finish coating in educational and medical institutions, business offices.

On the outer surface of the acoustic drywall Rigiton is a certain type of perforation (round, square). On the back side of the product, like in most other types of data of drywall constructions, a sound-permeable nonwoven fabric is placed. It is this coating that provides a good level of sound insulation of a finishing material.

It should be noted separately that the models of drywall of this manufacturer can boast a special system for air purification. And also it must be said that such panels have their own unique seamless design. At the same time, they are excellent for painting. The dimensions of these materials are 3000x1200x12 mm.

Knauf plasterboard constructions are considered to be equally popular. They are also made with different perforations. They are often used in recording studios, cinemas, shopping malls, auditoriums.Their size is 2500x1500x12.5 mm.

In the manufacture of acoustic drywall Knauf on its back side, which consists of a non-woven cloth, put an additional special sound-absorbing coating. This provides a complete sound insulation material. Such drywall sheets are highly resistant to temperature fluctuations and moisture.

Advantages and disadvantages

Acoustic drywall sheets have a considerable number of advantages.

- Variety of uses. These types of drywall can be used as a facing material for ceilings and walls. And at the same time no seams will not be visible, so the processing can be done easily with a special reinforcing tape.

- Security. Acoustic plasterboard panels are made exclusively from environmentally friendly materials, so they are completely harmless to humans and their health.

- Easy painting. Unlike many other species, this drywall is quite easy to paint. But it should be remembered that in this case it is best to use water-based paints.

- Easy installation. Installation of acoustic structures does not require special expensive tools and repair professionals.After all, to lay such a coating will be able to almost anyone.

- Low weight of the product. Acoustic sheets have a small mass, which greatly simplifies the installation of the coating.

But it should also be noted that thanks to this property, such drywall can be installed on light-weight flooring without fear of destruction.

But despite such a wide list of positive qualities, acoustic drywall has its own specific disadvantages.

- Do not apply decorative coatings.. Acoustic plasterboard constructions can only be painted, but it is impossible to cover them with anything else. After all, if you close the perforation with plaster or wallpaper, it will lose all its properties. Sound insulation will be bad.

- Low resistance to moisture. Most types of such acoustic products, when they hit a certain amount of water, swell and lose their original appearance.

- It is difficult to install additional items. To mount lights or decorative objects on the surface of such drywall is quite difficult. This is because it is too fragile.In addition, complicates the installation and perforation on the surface of the material.

Installation

Before laying the drywall coating itself you need to make a frame construction. To do this, firmly fasten the guide metal profile around the perimeter of the room. Between themselves, such elements are connected using conventional screws.

After installing the frame it should be filled. As a rule, do it with glass wool. After all, this material boasts excellent fire resistance and sound insulation. Many experts also recommend that the filler be covered with a special insulating film.

After filling the frame, you can break the installation of the drywall. To do this, the sheets need to be attached to the profile with screws. You can disguise their protruding parts with a simple putty.

Then you can proceed to the finishing finish of drywall. Most often acoustic plasterboard panels are painted after installation.

It is important to remember that before applying any decorative layer the surface of the sheets should be carefully cleaned of dust and other dirt.

Reviews

Today on the Internet you can find a considerable amount of consumer feedback on acoustic drywall. Many buyers have noted the high quality of such products. According to most people, this type of finishing material, indeed, has a high level of noise insulation.

And also some consumers separately noted the affordable price of acoustic drywall. Most confidently asserts that the purchase of such products will be affordable for almost anyone. A considerable number of buyers spoke of easy installation, which does not require the involvement of specialists in repair.

Many people said about lightweight panels. This greatly simplifies the transportation and installation of products. And also some users have left good opinions about the appearance of the material. According to most experts and buyers, acoustic drywall is quite suitable for decorative decoration of the room.

But despite the many positive reviews, on the Internet you can see the negative opinions of consumers. So, many noticed that during installation a large amount of construction dust and debris is formed,which is subsequently hard to remove.

Some of the users said about the excessive fragility of this finishing material. After all, such drywall sheets can easily break during transportation.

If you want to buy acoustic drywall, then you should think about how to save it and not to spoil it during transportation.

How acoustic drywall works, see the next video.