Characteristics and use of solvent 647

When carrying out repair and decorative works, one cannot do without special compositions. When treating surfaces with varnish and paint, solvents are often used. A rich assortment of formulations offers ample choice. Among the many products, the solvent 647 is widely used. The technical and operational characteristics of the composition have made it the leader among a rich product range.

Description

To date, solvent 647 is included in the list of the most popular and common formulations. Its peculiarity lies in the fact that ethyl cellosolve and acetone are absent in the composition. Due to this, the solution is considered more gentle and can be used when cleaning plastic surfaces. P-647 is chosen when in the first place a careful attitude to the surface being treated.

The solvent is often used in the coloring of road transport, since it can be used in conjunction with nitrolak and nitroenamel. The product can be found in almost any store specialized in repair and construction.

When using solvent together with nitro enamel, the film formed should not take on a white color upon evaporation of the composition. All minor defects, such as scratches, strokes on the surface of the enamel are smoothed and aligned without effort.

Specifications

Solvent 647 has the following specifications. which are confirmed by the relevant resolution of GOST 18188-72:

- appearance - transparent composition, which may have a light yellowish tint;

- texture - homogeneous (no suspension);

- water - the maximum rate of 0.6%;

- volatility (ethyl ether) - from 8 to 12;

- coagulation - at least 60%;

- density - 0.87 grams per cubic centimeter;

- the maximum acid number is 0.06 mg KOH per gram;

- density - 30.87 g / cm ³;

- flammable liquid;

- the storage period of the solution is exactly one year from the date of manufacture;

- self-ignition occurs at a temperature of +424 degrees Celsius, flash - 5 degrees Celsius.

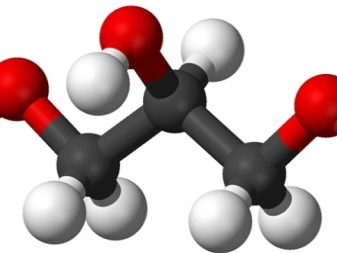

Composition

Solvent 647 includes the following elements:

- toolol (41.3%);

- butyl acetate (29.8%);

- butyl alcohol (7.7%);

- ethyl acetate (21.2%).

Using

In addition to its intended purpose, product 647 is used to increase the viscosity of materials that contain nitrocellulose. Compared to a similar solvent labeled 646, it is less active, thereby not damaging plastic surfaces. It can be safely used to gently clean the base from varnish and enamel. If necessary, the solution is added to various paints and varnishes. In the process of the fluid must be constantly and thoroughly mixed for even distribution.

The proportions are determined by the instructions. They differ according to the composition of the paint or enamel.

Storage

Before using solvent 647, You should definitely get acquainted with the basic rules of operation and storage.

- The composition must be stored in tightly closed packaging. Direct rays of the sun should not fall on the packaging.The room must have a high level of fire safety. Keep the solvent out of the reach of children and animals. The ideal location is a dark and dry room in which room temperature is maintained.

- When using it is necessary to ventilate the room. If there are no windows, and ventilation cannot cope with the volatility of the solvent, fans should be installed in the room.

- On the product packaging must be indicated instructions on the use of the product.

- Solvent 647 is sold for both industrial and residential use. Packages in the size from 0.5 to 10 liters, as well as large steel barrels for bulk purchases are presented to the buyers' choice.

Work

Solvent 647 is a flammable liquid. Product P-647 belongs to the 3.1 class of flammable liquids. In the process of work, you should avoid sparks, smoking and open flame. Air mixtures and vapors are also explosive. Air pollution by solvent vapors will pass quickly at a room temperature of 20 degrees Celsius above zero. When spraying solvent air pollution pass even faster.

Experts point out that if handled carelessly, the composition could be ignited from a distance. Accumulations of volatile substances are heavier than air, due to which they spread along the ground. The interaction with effective oxidizing agents (hydrogen peroxide, acetic acid and nitric acid) can cause an explosive peroxide. Despite the fact that the solvent of the above brand can be used to clean plastic surfaces, the substance is aggressive towards its individual varieties.

The composition enters a dangerous reaction with bromoform and chloroform with the possibility of fire or explosion.

Basic security measures

The use of a solvent provides for strict adherence to relevant sanitary norms and safety rules. All such compounds available on store shelves irritate eyes, skin and respiratory tract.

If you do not provide thorough ventilation, the solvent will cause a strong cough, and these negative effects are also possible:

- loss of creation;

- headaches;

- dizziness;

- blurred mind:

- food poisoning;

- intoxication;

- weakness;

- irritation;

- nausea.

Protect yourself from the above and other negative consequences will help special working clothes and accessories. Do not do without goggles, gloves and masks that will prevent the ingress of toxic substances into the respiratory organs.

The solvent can even affect the bone marrow and blood. In the event of contact of the solvent with exposed skin, it is necessary to immediately rinse the affected area with soap or other foaming compound. Otherwise, direct contact may cause dermatitis.

The vapor formed by volatile components in the composition is highly irritating to the respiratory tract and eyes. It is possible poisoning due to improper handling and neglect of safety rules.

Individual elements have a negative impact on the internal organs (stomach, intestines, liver) and the nervous system. The components of the solvent enter the body through the skin or in the process of inhalation.

Packing and transportation

Solvent formulations are sold in metal or glass packages. Products are transported using special road transport. For the transport of industrial volumes of goods used railway tanks.

Due to the increased fire hazard and easy flammability, special transport measures are necessary. The container used to transport the solvent must fully protect the solution from moisture and direct sunlight.

Differences of compositions 646 and 647

To make the right choice among solvent compounds, it is necessary to know the technical characteristics of the product. Solvents with 646 and 647 are among the leaders in popularity now. The main difference between the above solvents lies in the composition. In the manufacture of the product 646 manufacturers use acetone and ethyl cellosolve, which are not in solution P-647.

Acetone makes the composition more aggressive, in connection with which the brand 646 is not chosen when processing delicate surfaces. This is a highly active compound that must be used carefully so as not to damage the paint layer. The components available in both solvents are toluene and butanol.

See the following video for the difference between thinner and thinner.