Wood stains: types and scope of application

Wood products are very popular. However, like other materials, the tree is a favorite habitat for mold, fungi and harmful insects. To increase the service life of products made of wood used protective coatings - stain, which have not only an antiseptic effect, but can give color to wood.

Special features

Wooden products are durable and durable, but at the same time exposed to adverse natural factors. Today, the market of building materials presents a huge variety of special tools with which you can protect a wooden surface from possible damage. The most popular and affordable tool is a stain.To many, it is known as a substance that changes the color of the product. But this tool has many other wonderful properties.

The main difference between the stains from the paintwork is that the components of the stain stain the tree from the inside, while preserving the design of the product. And when painted with paint or enamel, an opaque film is formed on the surface of the product.

Properties of morilok directly depend on their component composition. Even with self-surface treatment, this tool will have certain beneficial properties.

The main properties of morilok:

- changing the color and texture of wood, while the drawings are not painted over completely, but the product acquires an interesting shade;

- protection of home furniture from pests, rotting without changing the texture and pattern;

- increasing the service life of wooden products several times, while the tool is much cheaper than varnish or paint;

- deep penetration into the tree structure;

- products from inexpensive wood species covered with wood stain will look more expensive and more refined;

- brightening wood - this property is usually used before painting the surface;

- moisture protection function;

- the possibility of combining colors.

However, not all stains have such properties. To choose the right tool for repair and construction, it is necessary to study the composition and instructions for use. Wood stain can be processed not only wooden surfaces, but also a chipboard, plywood, a parquet.

Kinds

Different manufacturers of stain are different basis. Each composition has its advantages and disadvantages, so it is necessary to choose a stain based on the desired results and timing.

Water stain

Water stain is usually sold in ready to use form. It happens liquid and powder, before applying which is previously dissolved in water. The final hue depends on the percentage of powder and liquid. Before surface treatment, the composition is filtered to remove undissolved particles.

The main advantage of waterborne paints is that they do not emit a specific odor, so they are usually used to treat the interior.

Water composition emphasizes the dignity of wood, hiding the defects of fibers. This stain dries around 14 hours.

The disadvantages include the appearance of roughness on the surface after processing, as a result, the wood is more susceptible to the effects of high humidity. To resolve this problem, you must:

- to grind the processed surface after full drying of impregnation;

- spray the surface with water and leave for a while, then you can apply the composition.

Alcohol and nitromorilki

The composition of the impregnation is introduced alcohol or solvent. Sold in finished liquid or powder form, which must be dissolved before use.

After processing, the coloring components are absorbed into the wood, only alcohol evaporates. Therefore, the stain dries no more than half an hour. The rapid drying of the composition provides for a rapid application to the wood in order to avoid the appearance of irregularities and stains on the surface. It is not very convenient to apply alcoholic stain manually, therefore it is recommended to use a special solvent.

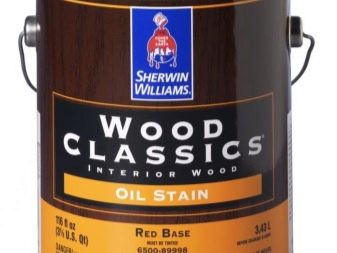

Oil stain

Oil stain is a composition using special oils. Thanks to them, this type of coating is considered the most environmentally friendly, since it does not emit harmful impurities into the environment.Therefore, it is widely used to protect wooden furniture.

Advantages of oil stains:

- fast drying - about 3 hours;

- deep wood impregnation;

- reliable protection from moisture;

- resistant color treated wood for many years.

Acrylic stain

Acrylic stain is produced in liquid form. The various palette of shades allows to receive any necessary tone of impregnation. Acrylic composition does not have the disadvantages of other types of stain, therefore it is considered the most expensive option. Main advantages:

- quick drying;

- without smell;

- free of toxic emissions into the environment;

- smooth surface coating;

- reliable protection of wood from high humidity.

Wax stain

Wax stains appeared relatively recently in the field of protection of wooden materials. Impregnation is a non-aqueous composition, which, without penetrating the tree, forms a protective film on it. Therefore, wax formulations are most often used for outdoor work. They are painted as a base for paintwork.

To use this stain you need a dry soft cloth. Thus, the processing eliminates stains and a decrease in moisture resistance.

Consumption

Since the stain has a good absorption capacity, the degree of porosity of the material should be taken into account when calculating the flow rate. On average, the processing of 15 square meters. m consumes one liter of impregnation. You also need to know that the impregnation colors different wood differently. For example, the oak staircase after treatment with stain will acquire a dark brown color. At the same time, the pine or maple surface will turn yellow.

Conifers do not absorb wood stain very well. In order to avoid uneven coloring it is necessary to saturate them in several layers, as a result of which the material consumption will double. Therefore, it is recommended to remove the wood resin from the base in advance.

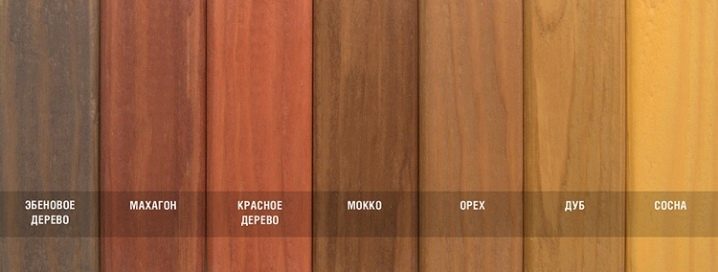

Colors

The stain has not only a protective function, but also gives the surface a noble shade. Since the structure of wood is heterogeneous, some areas impregnate the composition less, and others - to a greater extent, due to which, after the composition has dried, the natural patterns of the wood are emphasized on the surface.

Today, the stain can dye wood products in any shade, but the most common is the "wood" colors.Their name corresponds to a certain type of wood. If not on the shelves of the shade you like, you can get it yourself by mixing several shades.

When choosing a protective agent in a specialized store, you need to ask the seller for samples of the product covered with a particular shade of stain. Since each manufacturer produces different shades of impregnation with the same name, it is necessary to consider in detail the provided wood samples.

The saturation of a hue directly depends on the type of wood, the original hue, porosity, texture and density. If coniferous trees do not quite “digest” the stain because of the presence of resins, so the hardwood soaks to the maximum. For example, if you cover with impregnation mahogany and maple, then the first shade will turn out much darker.

To give wooden products a light shade they do not have to be painted. The best option would be lightening impregnation, which will lighten the surface, as well as emphasize the structure.

If there is a high probability of moisture getting onto the white product, then it is best to stop your choice on wax,oil or acrylic types of impregnation. If water does not fall on the processed products, then water-based impregnation will do.

In addition, brightening stain allows you to get a vintage interior. To do this, after painting with a white water stain, the surface should be treated with a stiff brush. After staining with a water stain, one should not forget about the need for additional surface treatment with wax or oil stain.

Light shades of wood stains do not always give rich colors. There are also colorless types of impregnation, which are necessary to protect wooden products from exposure to adverse environmental conditions.

Gray shades will help avoid the selection of furniture from the general interior. This color is recommended to apply only in cases where the walls and textiles are made in bright colors. Gray color causes melancholy; besides, a tree in a gray shade will look dull and faded.

Psychologists say that the most suitable option for all is a green stain, since it is this which causes positive feelings. All shades of green will be an excellent option for processing any interior items.Blue stain will help make expressive individual products, especially in combination with white and yellow shades.

Manufacturers

Today there are a lot of manufacturers of wood protective coatings. Among them are considered popular German companies. Flamingo, Dufa and Caparol. Turkish manufacturers are also no less known: Betek, Dyo and Marshal. They have an impeccable reputation for wood materials. Relatively recently, Slovenian enterprises producing protective materials appeared - Hellios and Belinka Belles D. O. O., however, they have already gained respect among many buyers.

Domestic company Novbythimsince 1994, produces a wide range of products.

The company has great potential, thanks to which customers can expect the emergence of more and more innovative materials that will be in demand both in the professional environment and for independent work.

No less popular are products of a famous manufacturer. Liberon. The company was founded in the XIX century and specialized only in the production of paints and varnishes. Now the company produces materials for the protection of wood, paints and varnishes, tinting.The company's products have only good reviews, so the manufacturer has gained a reputation as a reliable manufacturer. Among the rich assortment it is possible to single out the most popular products: aggregates, wax materials, protective stains.

Tips

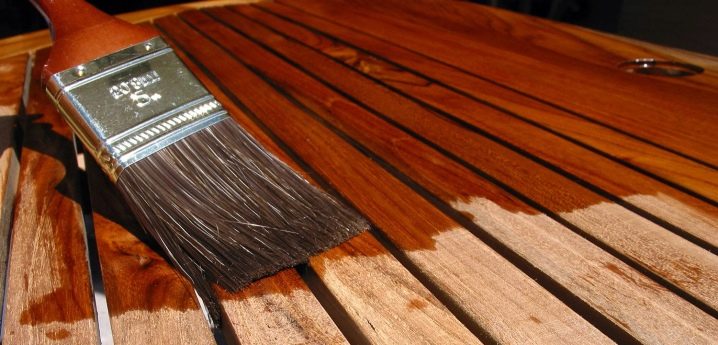

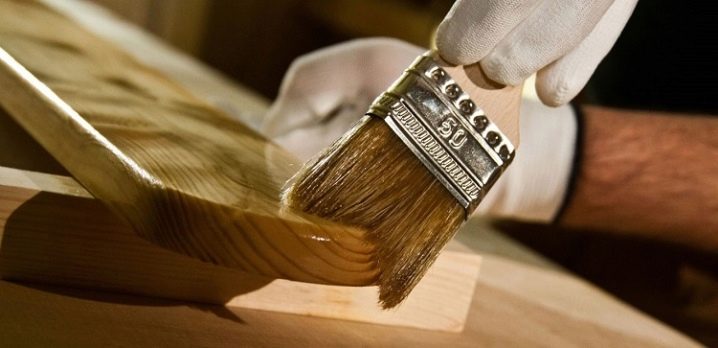

The type of application depends on the type of stain and the size of the product. For these purposes, use a tampon, brush or spray paint. It is not recommended to use a brush for treating a large surface, since it is likely that traces of its villi will remain and it will take a long time to process.

It is more convenient to work with a large area by a sprayer. For this, it is necessary to choose a lighter shade impregnation, since the applied layer will be thicker than usual. At the beginning of the work, one should not forget to cover non-treated surfaces with a film.

For processing oil means it is better to use a tampon. It can be made independently using foam rubber or cotton wrapped with cotton material.

If, nevertheless, there is a desire to apply the composition with a brush, then it is necessary to choose a brush with synthetic bristles for water-based paints.You need to buy only high-quality tools that will not leave the villi on the wood.

After selecting the appropriate shade and instrument, it is necessary to make a test vykras. This is done in order to find out the required number of layers of stain to obtain a particular shade. For this you need:

- take a small sample of wood material of the same breed as the product for painting;

- polish the plank in the same way as the main product;

- cover it with impregnation and leave to dry;

- apply the next layer on two thirds of the wood;

- when the last layer dries, apply the stain on the remaining one-third of the plank;

- compare color saturation and choose the optimal hue.

The stain is applied to a wooden surface without coating: it can be a completely new product or part from which the previous coating has been removed.

Dry wood needs sanding with sandpaper. During work, you can not push hard on the tree, you need to move only along the fibers. This will avoid the appearance of minor defects on the surface. If they are almost invisible before painting, then after treatment by impregnation the defects will be strongly emphasized.The grinding process takes about 30 minutes, this is enough to get a smooth surface and pores to penetrate the stain.

After grinding it is necessary to remove fibers and dust from the product with a vacuum cleaner. Using white spirit or gasoline, degrease the surface of the part. In the end you should spray the tree with water, so the impregnation will fall correctly. Shake the jar thoroughly to mix the contents. Then you need to warm up the stain to medium body temperature, so the composition penetrates deeper into the wood structure, then moisten the brush or tampon for dyeing in impregnation. For the sprayer - pour the stain in a special vessel.

During the processing of vertical products move upwards. If the composition will drain, stains will remain almost imperceptible. For processing horizontally lead brush along the fibers, then across, and then again along. It is important to distribute the stain carefully and monitor the uniformity of application. In order to avoid stains, the composition is applied as quickly as possible. Before applying the second layer of stain, it is imperative that the initial layer is completely dry.

After complete drying of the composition on the surface, the final process of wood processing is carried out. Using the wash removes excess impregnation, which remained not absorbed into the surface. After this process, the product looks different: shine appears, texture. Washing is carried out with acetone using a bulk brush as follows:

- tilt the product slightly;

- under it put absorbent fabric;

- dip the brush in the liquid;

- brush down to drip excess impregnation;

- continue to act until a uniform surface appears;

- leave the products to dry and then apply varnish.

How to make a wood stain for your own hands, see the next video.