Features the choice of varnish for interior and exterior

Among the various mixtures for coloring in the first place are various varnishes. They are often underestimated and are considered less relevant than paints or enamels. But in fact, it is only necessary to carefully select the finished mixture and evaluate its characteristics.

Special features

People started to apply lacquer to the walls for a long time, due to their excellent protective and finishing parameters. The varnish can be used to apply on metal, plaster, planks or cant, as well as on many other surfaces.

The most widely used in practice are mixtures created on a water basis. Varnishes for outdoor work must be resistant to adverse weather conditions. For compositions used in interior spaces, this is not very significant, but decorative properties, resistance to abrasion and sanitary safety are much more important.

Varnishing the surface allows you to solve a variety of tasks:

- increase the strength of the surface to be trimmed - replacing glue for peeling or weakened parts;

- protection from destructive thermal and chemical effects, changes in air humidity;

- suppression of the activity of microscopic fungi and microbes;

- maintaining rich bright tones;

- blocking the action of ultraviolet rays.

Kinds

Such attractive properties cannot be realized with the same degree with the same composition, therefore the chemical industry has launched a significant range of varnishes. Water soluble formulations are either matte or glossy.. At the factories, a solution of dry emulsifiers in water is mixed using special equipment.

The formulation almost always includes additives that help the formation of protective films on painted surfaces. Single-component varnishes are created using acrylic or urethane compounds, and in two-component mixtures, both are immediately present.

Water mixtures are mostly used indoors, polyurethane variants are preferred where a large flow of people is constantly moving. You can cover the walls with such varnishes.

Also, if necessary, regular wet cleaning should be carried out using detergent and abrasive compositions.

Therefore, the main objects of use of polyurethane coatings are:

- administrative and office buildings;

- educational institutions;

- trade organizations;

- institutions of health, culture and mass leisure.

Acrylic lacquers have their advantages: they can and should be used where the main thing is not wear resistance, but the elasticity of the layer created and its microventilation. These qualities are extremely important for living rooms with a simple operating mode. Regardless of the chemical composition, water-based varnish must be stored at positive air temperatures, otherwise it will deteriorate.

The disadvantage of acrylic blends is the increased cost. In addition, they dry the whole day, and finally the polymerization is completed only after two weeks.

Coating with a panel lacquer is a type of surface treatment with water mixtures. Compared to other options, this finishing material attracts attention with impressive environmental and sanitary characteristics.Modern technologies allow to form a layer of pronounced tonality, and completely colorless in appearance.

Steam admission is very important when finishing wood panels, as otherwise excessive pressure will build up inside the material.. Other positive features of this option are resistance to swelling, shrinkage and household standard pollutants.

It is convenient to use lacquers in the form of an aerosol - while their protective properties are no worse than that of a liquid package. The chemical composition is the same: acrylic or polyurethane. After application, there will be no problems with bad odor or prolonged drying.

Part of the aerosol lacquers is made on the basis of nitrocellulose, and already 60 minutes after surface treatment, they become safe in sanitary terms.

Glossy reflux is recommended when the room is finished in dark colors, and you can provide the necessary strength if you do not save on product quality.

Transparent balloon varnishes look harmonious even on expensive types of wood and do not spoil their appearance. If the base is made of cheaper wood or stone, concrete, brick, then it is worth making a choice in favor of color composition.

In those cases where deep absorption into the surface is very important, water-based mixtures are undesirable. It should be noted that treatment with aerosol lacquers can only be done outdoors or with intensive ventilation, away from open flame and sources of intense heat.

It is recommended to paint any material in two or three layers - it will take about 15 minutes after each treatment.

Enhanced decorative features has varnish with sparkles. They are holographic, rainbow colored or imitating the light of neon lamps. In the rays of reflected solar or electric light, such coatings look bewitching.

A little way aside, it should be mentioned that there is even a varnish for printed circuit boards. It is unlikely that anyone will consider these details, except for repairmen and specialists. therefore cover them exclusively for protection against water. The required mixture is formed by mixing polyurethane and epoxy components, but technologists are actively working to obtain simpler one-component mixtures.

Sometimes varnish is applied to the walls under alkyd paint - in this case, the appearance of smellwill be a critical moment. It is important to remember that alkyd and acrylic components do not tolerate each other. If they are used in any combination, a swelling inevitably appears, and soon the painted surface will look ugly.

It is recommended to choose a lacquer as close as possible to the paint chosen for finishing. It does not matter what material will be applied below, and which above - compatible with each other coating is still safer.

The polyether composition differs in that it forms an insoluble film on the surface, the thickness of which varies from 300 to 400 microns. For the most part, such mixtures are applied by spraying or pouring installations. If you polish the surface, it quickly becomes a mirror.

Luminous (fluorescent) wall varnish belongs to the category of specialized mixtures - such paintwork materials create impressive effects, but It is recommended to entrust all works to professionals.

The marker version converts any surface on which it is applied, in the similarity of this marker board.

Colors

Choosing a practical type of varnish and making sure it is safe,you need to choose the color, because the color of the trimmed wall or other surface will have to look in the next few years. And if he is illiterate, the result may be disappointing.

Mother of pearl shade recognized by all designers one of the best options - it will be difficult to forget a room decorated in this way. Such a decoration can serve as the main design element, as well as secondary, only emphasizing the main background.

Glossy varnish is worse than matte, if the walls or other surfaces have clearly noticeable irregularities. It will only highlight them more and accentuate the attention of guests.

Even in an ordinary house it is unpleasant to talk about organizations that, thus, may lose their reputation. Is it worth enhancing the brilliance of carrying out the most careful leveling work - it is up to the consumers themselves to decide.

Silver color in the interior is attractive because it is almost universal and combines with many other tonalities. Interior design experts believe that the best combinations of silver paints are formed with bluish and light blue hues.. But also attractive solutions will be combining of such color with such shades as green, orange (when diluted in space with other, less energetic colors), violet and light brown.

Colorless varnish is good because it does not attract attention and can serve as a simple protective film on the surface, as well as a substrate for more pronounced and saturated colors.

Black color immediately attracts views and can even become dominant in the room or on the outer wall. But solid black or combination with other very dark colors is not recommended. Such a design move does not justify itself, and even creates the impression of something gloomy, heavy, grave.

Having finished with the choice of tonality, you can proceed to assessing the quality of products from different companies.

Manufacturers

Company "Eteral" delivers polyurethane varnishes with enhanced anti-corrosion, strength characteristics. There are options for concrete surfaces and floors, for painting wooden and metal surfaces. Finishing concrete floors and other solid foundations can last at least 30 years after application.The developers made sure that the line contains proposals for a variety of temperature and humidity conditions.

Lucky VGT Acrylic for exterior and interior work to the same extent, while you can finish any surface of wood, with the exception of floors. The formed film is at the same time transparent, strong and well stretched. In the process of drying, the color gradually changes from milky to colorless tonality.

Consumers can tint the resulting coating in any color convenient for themselves, and this will not affect the unprecedented resistance to ultraviolet radiation. You can paint concrete, stone and other materials.

Firm "Lakra" supplies water-based acrylic lacquers, which, in accordance with the generally accepted approach today, are well protected from UV rays. The Lacra range also includes solvent-based paint products. This group includes mixtures for painting parquet, furniture, other wooden and metal products. Chemical basis - acrylic or nitrocellulose.

Reviews on the products of the famous Finnish concern Tikkurila are always complimentary - the manufacturer does not hide the important points and brings them to the consumer in the public technical documentation.There are in the range of protective, high-gloss, semi-gloss compositions. Each of them is very reliable and has a high service life.

How to choose?

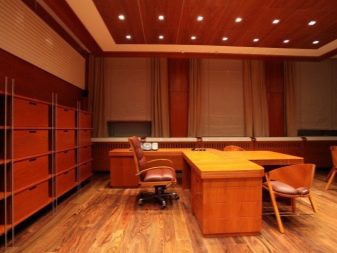

In most cases, lacquer coating is used for wood finishing, because it allows you to preserve the inviolability of natural texture and color. On the street, any walls, wooden structures and elements are constantly exposed to excessive moisture, temperature changes and ultraviolet irradiation. because for exterior work only those mixtures are suitable, the technical documentation and marking of which show their readiness for such impacts.

For walls and furniture, the load will be different, because where people walk, only the most durable mixtures can be used.

For the sake of maximum savings, you should not buy inexpensive toxic varnish - you will have to use it, wearing protective clothing and respirators. Even in this case, such a finish is permissible only for non-residential space.

Waterborne varnish does not contain toxic components at all, and it should be chosen when there is no opportunity to move to another room during the repair. It is important to know that water and oil formulations are dried for a very long time. - the period of their drying sometimes reaches up to 72 hours.

The most operational - dyes based on alcohol or nitrocellulose. This circumstance must also be taken into account when choosing, focusing on the necessary time for work.

For rooms where there are sources of open fire or heating devices, it is recommended to choose heat-resistant varnishes.

No matter what sellers and manufacturers say, the aesthetic parameters of varnish mixtures do not affect their use. If you plan to do all the work yourself, one-component compositions are the best solution.. But professional builders and furniture makers prefer two-part dyes, because they allow you to make the coating more resistant.

It is important to distinguish between lacquers that require primer and mixtures, from compounds that do not require them.

Increasing the concentration of the main reagent in the oil lacquer helps to improve its protective properties, but at the same time the drying time will increase.

Alkyd compounds are recommended in cases where you want to emphasize the original tree pattern and create many layers. For the most part, such mixtures are used for finishing floors, and if urethane components are introduced, the performance can be significantly increased. In any case, alkyd varnish has a disgusting smell. Alkyd-carbamide finish is recommended for parquet and solid wood.

Usage tips

It is important to note that after painting the floor with silicate water-based paints, it is absolutely impossible to apply water-based varnishes - they simply wash the substrate, completely destroy it. As with any other coatings, the surface should be carefully prepared. Responsible builders are not limited to removing dirt and dust - they wash and dry the walls.. It is possible to apply water varnishes over acrylic water-based paints without any fear.

Painting the ceiling with varnish allows you to keep the charm of natural wood and even enhance its attractiveness. Acrylic coating is recommended for situations where you need to preserve the natural color and ensure maximum safety.. Alkyd varnish is more expensive and can only be applied to thoroughly dried wood.But it allows you to make the surface radiant and cover it from the harmful effects of moisture.

It is not recommended to cover the wooden ceiling with a dark layer unless absolutely necessary - the result will look gloomy and degrade emotions.

It is very important to combine with each other the color of the floor covering, the finishing of the walls and the ceiling, even if on the principle of contrast - they must form a single composition. In the bedrooms always use only colorless mixtures, and the offices and living rooms are painted with strict, restrained shades. We must not forget which colors are pushing the space, and which - are absorbing. Sanding a tree when preparing the floor regardless of the method is allowed only along fiber linesWhether to apply the stain depends on the specific situation.

Herself varnishing starts from the window and is carried out in the course of the light. If there are gaps in the tree, then they are lubricated first, and only then they are taken for the surrounding space. Be sure to check that there are no drops and drips. The best temperature is not lower than +15 and not higher than +18 degrees; windows can be opened, but it is advisable to avoid drafts.

If after two layers there is still material, then you can use it for the third varnishing - such a technique will only make the coating more qualitative

Make a varnished in the bath outside will help epoxy compounds. But by the sum of practical characteristics in the first place are polyurethane combinations. It is unacceptable to use parquet lacquer - it is too hard and blocks the natural drying of wood. It is possible to paint a bath only after reducing its humidity to at least 20%. Having processed the walls with flame retardants and antiseptics, you should wait 14-20 days before painting.

The best varnish for the premises of the house is one that perfectly meets the requirements. For example, mechanical durability is very important for parquet finishing. In the bedrooms and other less-attended rooms, the load on the floor is less, and therefore it is possible to do with a relatively unstable budget cover.

To water varnishes did not increase the creak of the floor, the base is advised to be primed with similar mixtures.. Adding additives that increase resistance to wear is permissible only in rooms where the humidity does not exceed 50%. It is necessary to work with formaldehyde varnishes strictly in a respirator, any tools are suitable for their application.

How to choose a varnish, see the next video.