How to choose a varnish for wood?

To ensure the protection of wooden products using a variety of means: impregnation, varnishes, paints. In order not to get confused in the choice of a particular means, the buyer should know some subtleties of choosing such a composition.

In this article we will discuss the nuances of choosing varnish for a wooden surface.

Special features

Varnish is a viscous composition derived from dissolved resinous substances and polymers. When applied to the surface of such a substance forms a shiny film. This coating is used to protect the outer layers of the tree, since they are highly vulnerable to various influences.

Thus, the life cycle of wood products with the help of the applied substance will be extended.

The properties of each coating composition depend entirely on its components. For example, using alkyd substances, it is possible to protect the wooden coating from moisture, and with the help of alkyd-urea compositions, the coating gains additional strength.

Kinds

The most important criterion of any coating composition is its brilliance.

Therefore, the parameter protective substances for tree species are divided as follows:

- High gloss lacquer. The brightness of the reflective light from the surface of the tree in this composition reaches 90%. This finishing material is the best in quality gloss.

- The composition is glossy. The described parameter ranges from 80-90%.

- Semi-gloss varnish. When using such a composition, the gloss parameter takes values from 40 to 50%.

- Semi matte material. Gloss has parameters of 10-15%.

- Matt lacquer. The brightness of the reflecting light from the surface is less than 10%.

Coatings are also divided by application - they are both for outdoor and for indoor work.

Varnishes for interior work. Such compositions are especially popular, because they not only protect surfaces from various kinds of influences, but also decorate them, making any wooden product beautiful and pleasant to look at.

Specialists such varnishing compositions are divided into several types:

- parquet;

- furniture;

- universal.

Parquet

Designed to cover parquet. This board needs a high-quality protective coating, so manufacturers recommend using this category of paintwork materials for this. In addition, the lamella coating after the application of such a composition acquires a rich and refined appearance.

Parquet coatings have a wide range: in the shops you can find both matte varieties and glossy ones.

When choosing this composition, you should focus your attention on several criteria:

- Room in which additional protection is required. For example, if the homeowner wants to varnish the bedroom floor, then there is no need to use expensive varnish, because in this room there are no special effects on the floor, which is not the case with a corridor or kitchen.

- Technological features of the composition. Here, the consistency of the substance and the method of its application are important factors.

- Type of product. It is presented in the form of a transparent substance or has a certain tinting.

- Gloss level. This refers to haze or gloss.

As mentioned above, it is measured as a percentage.

- The stability of the composition to various external influences: ultraviolet, loads and other equally important criteria.

- Coverage service life.

Parquet lacquer can be divided into several varieties, RFly about them will go below:

Primer composition

It is used to enhance the adhesion with wood at the initial stage of processing. It is necessary if you want to get a flat color gamut of the product, as well as to isolate the wood species from moisture effects.

Using such a composition, you can save a lot of money, because the finishing coating will require very little. When choosing it, you should be especially careful - the substance must fit the finishing component of the finish.

Water soluble composition

Consumers choose such a composition most often, because the ratio of price and quality is optimal here. The composition of this substance contains not only water, but also various solvents and emulsifiers. Due to this, such a product dries a little longer than its counterparts.

These compounds have several varieties, differing in the absence or presence of a percentage ratio of solvents, which is either 5% or 15%.Among the positive aspects of the use of this composition is the absence of any odor, as well as its incombustibility.

There are much more negative sides, however, this fact has practically no effect on the popularity of this product among consumers.

The disadvantages of using this composition include the following items:

- At the time of applying such a solution is able to penetrate into all the cracks, which creates some inconvenience - a creak appears in the floor. This nuance can be corrected by using a primer in the initial stage, which should include water.

- Another disadvantage of using such a composition is poor wear resistance. It is possible to improve this characteristic at the production stage: manufacturers use special substances as additives in the composition - additives. However, it is possible to use this water-soluble varnish only in the absence of high humidity in the room: manufacturers advise to use this paint and varnish at a rate of less than 50%.

- When applying a water-soluble composition, rollers should be used: brushes and sponges are undesirable for this process.

Polyurethane

The main purpose of this product is the additional protection of the coating from external loads. The composition has high adhesion and dries quickly.

Additionally, it is worth noting other distinctive features of this material:

- Polyurethane compositions consist of either one component or two. Therefore, they are recommended to mix thoroughly before applying.

- In the production of such substances using a solvent, as well as urethane or acrylic.

- When applying and drying the composition, it is necessary to ensure its protection - it is impossible to allow the ingress of water or moisture to the substance.

- The use of this product allows the absence of an additional primer layer.

- The composition is highly elastic.

- The use of the composition is possible without special requirements for the temperature of the room.

- During operation, the plane where the polyurethane varnish was applied will not be afraid of water.

Alkyd

In the production of this substance, manufacturers use natural ingredients - oil resins. They are woody components or flaxseed substances. These components penetrate well into the structure of the wood flooring and reliably protect it during the whole service life.

Alkyd substances are quite toxic components - in their composition one can often observe such an ingredient as white spirit.

It is worth noting a few of the distinctive qualities of this composition:

- When applying alkyd components on the tree, its texture becomes brighter, which enhances the natural beauty of the breed.

- Using such a varnish, the consumer will forget about the negative effects of moisture and mechanical stress.

- The alkyd coating differs from its counterparts in the non-fluidity of the solution, so when applied, the varnish will not spread and fall into all sorts of cracks. This means that there will be no problems with gluing wood to other materials.

- The moment of drying of such a composition should be accompanied by low temperature indices, since the varnish is rather sensitive to their elevated values.

- Alkyd substances have a low level of wear resistance.

- Apply this paint on the wood structure should be a thin layer, this should be carefully monitored.

Formaldehyde

The basis for such substances are formaldehyde resins.

They are very harmful to the health of others,therefore, in the process of applying it is necessary to use protective equipment - respirators.

The main characteristics of the use of this composition are the following positions:

- such paintwork is the most durable;

- usually this compound is applied as a final coating on a wooden surface without using a primer;

- the substance adheres well to wooden surfaces;

- this composition is not afraid of temperature surges and moisture;

- when applying this substance, you can use almost any toolkit: roller, brush and other objects;

- such compounds have an unpleasant pungent odor;

- the composition of varnish is thick, it must be taken into account, since there is a probability of gluing the boards together.

Some experts recommend using the following varieties of paintwork materials, depending on the purpose of the premises:

- for bedrooms, water-soluble composition is perfect;

- Alkyd composition of the substance can be used for the living room, loggia or study;

- Formaldehyde substances are commonly used in the hallway, in the hallway and in the kitchen.

Furniture

Applying paintwork materials for furniture, the owner of the house will receive not only an excellent variant of protection against external factors, but also thereby emphasize the natural texture of the wooden product.

Such composition for wooden furniture can be divided into the following types:

- oil;

- alcoholic;

- alkyd;

- acrylic;

- nitrocellulose;

- epoxy;

- polyurethane.

Oil

This coating can easily thicken during storage. Turpentine is usually used to dilute it. The application of such a composition should be carried out with a brush of high rigidity, you can also use a spray.

After applying the wooden coating will dry for a long time, because the oil composition does not have volatile solvents. To apply the second layer on the surface of the wood, it is necessary to wait for the first one to dry, after which it is recommended to clean the surface from dust and sand it. Before applying the third layer, the process must be repeated. The result should be a shiny glossy surface.

The surface treated with this composition is not afraid of moisture, ultraviolet rays and high temperature. To speed up the process of drying the composition, the processed product must be placed in a bright, ventilated room. with a low level of humidity.

After drying, the room should be ventilated until the unpleasant odor evaporates. Experts advise performing surface polishing to achieve maximum gloss.

To do this, use a swab soaked in alcohol. It can be made from a piece of wool or wool the size of a chicken egg. Additionally, this material is wrapped in a soft linen cloth. The lower part of the tampon is covered with a small amount of vaseline or sunflower oil. Then perform circular movements on the surface until then, until there remains dry places.

Alcoholic

This type of coating is made with the help of alcohol and natural resin ingredients.

The composition has the following distinctive characteristics:

- good adhesion;

- high strength to mechanical stress;

- great shine;

- The composition does not differ in moisture resistance.

Typically, such a composition is used for coating wooden surfaces that require polishing.

Alkyd

The basis for the production of this varnish for wood is a solution of synthetic resin and solvent. The film formed after drying is transparent and hard. In the process of coating the surface color range does not change. This coating is resistant to moisture and has excellent adhesion properties.

Acrylic

This composition has a base on water and is characterized by good strength. The wood covered with such paintwork will not change its color, and the texture of the wood species will be fully preserved. However, it is worth considering such a moment that the composition is not moisture resistant, so the use of this finishing material in wet rooms is not recommended.

Polyurethane (polyester)

This substance is characterized by the presence of polyesters and diisocyanates. It happens both one-component and two-component. Before applying, mix the isocyanate and the solution, obtaining the desired consistency for use.

These compounds are flexible and form a durable film. Additionally, it is worth noting that the coating is resistant to abrasion and mechanical stress. Furniture coated with this varnish will last for many years.

Nitrocellulose

The basis of this coating is a resin with the addition of colloxylin and organic mixtures. Suitable for application on any wooden surface. The varnish is distinguished by high strength, smooth surface and excellent decorative properties.

The optimum temperature at which the varnish dries in about an hour is 20 ° C.

Once the composition is completely dry, it will be completely safe for human health.

Epoxy

This substance is composed of a solution of epoxy resin and organic solvents.

The advantages of this type of paintwork materials:

- resistance to moisture;

- mechanical strength of the material;

- high gloss settings;

- harmlessness

Among the disadvantages is to highlight the exact observance of the technology of preparation, since the composition is two-component and poor elasticity. The composition is used to cover parquet, doors, furniture, windows and floor.

Universal

There are many options for universal formulations. Below is an example of one of these varnishes.

Varnish acrylic universal glossy Kudo. This composition is necessary to give the surfaces a decorative shine.As such surfaces are wooden, metal or plastic products. The composition is easily applied even to the surface where there is a layer of paint.. It should be noted that the varnish is universal not only because of its ability to be applied on a variety of surfaces, but also because it can be used both for internal work and for outdoor work.

The characteristics of the composition are the following characteristics:

- varnish is able to hide the defects of the coating;

- is reliable protection against abrasion;

- protects the product from mechanical stress;

- no peculiar smell;

- varnish is completely transparent;

- not afraid of moisture.

Varnish for outdoor work. Such a composition is characterized by reliable protection of the surface from environmental factors, taking into account all the individual characteristics of each wooden coating.

It is worth noting that this varnish is quite expensive, but due to the fact that the wooden surface will be under reliable protection, this fact can not be taken into account: over time, the cost of finishing material will pay off.

Color spectrum

The main task of the paintwork is to create a durable coating and give itcolor effect.

Using colored lacquer has several advantages:

- protection from external factors;

- decorative function;

- increases the life of the material.

Often for the interior homeowners acquire glossy lacquer - this applies to those premises that are quite dark. The colorless look is one of the few examples when the natural structure of a tree is emphasized by applying varnish.

When choosing a specific color range, you need to understand that it has a huge number of shades.

For example, covering the walnut paint with the color of the floorboard, you can get several different color effects. It can be beige, red, black or dark brown.

Homeowners love to use tinting compounds. They cover the doors, furniture, parquet. Wood gets unsurpassed appearance, as well as resistance to mechanical stress. On this surface will not form blue, fungus and mold.

Scope of application

As mentioned above, lacquer can be used both for internal work and for external work. It all depends on the composition, you must carefully examine it before purchasing.Varnish for interior work can be used for painting wooden furniture, doors, floors and other household items.

LKM for outdoor work is used to finish the following structures and elements:

- building facades;

- furniture parts;

- arbors;

- enclosing structures;

- wooden flooring;

- terrace structures;

- beams;

- log houses.

For application on large areas, you can use spray paint in a spray can or spray. A representative of this type of paint is bitumen varnish. It protects the surface from rotting, mold and mildew.

Consumption

Paint consumption depends on several indicators:

- Surface category. If the tree is endowed with deep pores, then the consumption of it will be clearly more than the usual wooden coating. For example, for ash and oak, the composition will require much more than a beech or pine variant.

- Composition viscosity. The viscous composition does not spread over the surface, which means that it will need much more.

- Paint consumption is also dependent on surface grinding quality. It should be noted that if the surface is polished well, then the varnish will need less than usual.

- Method of applying paint. Using a paint spray gun, you can greatly save on the amount of the composition. Roller and brush spend much more varnish.

The average consumption of paintwork materials is known: Usually about 8-10 square meters of surface are covered with 1 liter of substance. When applied with a second layer, the coating can process an area of 20 square meters. m

Applying varnish in 2 layers ensures color fastness and the required surface protection.

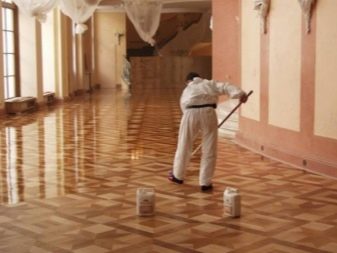

How to cover?

For varnishing wood texture should use the following application technology:

- The old surface must be processed using sandpaper.

- After that, the surface should be sanded and dust removed from it.

To polish the surface is more thorough, because the amount of paintwork material depends on it.

- If tinting varnish is used, then it is necessary to use wood stain.

- Then you need to apply a primer composition. At the same time it is necessary to follow all the rules for its use.

- The final step is the application of varnish using a brush, roller or spray.

For the convenience of the process should be applied varnish using a roller. Brush suitable for hard to reach places.In order for the brush to remain on the surface, it needs to be chosen with a slight fluff at the end.

As for the sprayer, they can cover large areas in a short period of time.

If you want to varnish the surface of wooden furniture, you should use two layers, and when treating the floor - three.

Manufacturers

Currently, manufacturers of paintwork materials have become much more than a few years ago. This is due, primarily, with the active construction of new buildings and structures.

- Among domestic firms It is necessary to allocate the company Technocolor. This manufacturer produces acrylic and polyurethane compositions for wood based on water. The color palette has more than 50 shades, including here you can find white and even red LKM. Also at this manufacturer there are also other types of LKM, but in more limited quantity.

Consumer feedback on the products of this company are positive. Buyers note the material's resistance to sunlight, the lack of yellowness after several years of operation of the processed product. Some formulations dry out pretty quickly.

- Among foreign brands stand out such companies like Dulux, Rustins Polyuretahane Varnish and Rustins OD Floor Varnish, Tikkurila. According to consumers, the products of all these brands have excellent quality, dries quickly, the surface after applying such compositions have a presentable appearance.

Tips

When selecting the composition should pay attention to the following nuances:

- Operating conditions. This refers to the conditions under which the varnished surface will be used. For example, if a wooden product will be on the street, then it is worth choosing a composition that will protect the building or garden furniture from such factors as high humidity, ultraviolet, temperature drops.

The manufacturer of all recommendations on the use and properties of paintwork materials focuses on packaging icons. In this case, it is worth using a waterproof lacquer for outdoor use. Parquet or wall materials should be treated with varnish for interior work.

- Wear resistance. Each coating has its own characteristics, so when painting, for example, the floor, you should pay attention to the strength of the composition - it must have high performance. For furniture, you can choose a less wear-resistant substance.

- Toxicity. Most water-based lacquers do not have an unpleasant odor. This aroma is inherent only to those compositions in which there are organic solvents. But also they become completely safe after their full drying.

- The duration of the drying composition. All funds can be divided into quick-drying and those that are characterized by a long period of drying. Usually, water-based compositions, as well as oil paints, have a long drying time. Depending on the composition, it can reach about three days. Alcohol and nitrocellulose formulations are the fastest drying substances - these varnishes dry for 20 minutes.

- Resistance to high temperatures. Compositions that form a fire-retardant film, will correctly apply to those surfaces that are near possible sources of fire. It is worth more carefully to apply a heat-resistant composition, the result of operation will depend on the quality of work.

- Gloss settings. Through the use of varnishing, it is possible to obtain both a glossy and a matte surface. It is worth noting that the glossy surface will visually give the subject of refining visual volume, and a matte effect will emphasize the naturalness of the wooden coating.

- The composition of the composition. If you need to get a resistant coating, it is better to use two-component compositions.

- Primer. You can choose as self-priming varnishes, and compositions that require preliminary surface preparation. The first option is applied directly to a wooden surface. When using the second option, the primer is obligatory, since otherwise the varnish will peel off after a certain period of time, thereby causing the appearance of cracks.

Sometimes it is necessary to clean the surface from the old varnish coating.

This can be done in several ways:

- using the wash;

- warmth;

- mechanically.

The first method involves the use of a special substance - washes. This substance must cover the entire surface to be treated with a brush.

Putting this paint on the surface must be accompanied by the presence of protective equipment - glasses and gloves - for the person performing this work.

Then the material is completely wrapped with a film - this is necessary so that the wash does not evaporate. A day later, the product is removed from the film and try to remove unnecessary coating with a spatula.If this does not work, then you should wait another 24 hours. It is possible that after this time has not been able to get rid of the old coating. therefore such an operation must be repeated until the old coating is completely gone.

After the surface is completely cleared of the old coating, it is rubbed with warm water. Then she needs to be given time for complete drying, usually it is 24 hours. After that, the surface is ground and a primer is applied under the varnish.

The second cleaning method is used with a soldering iron or construction dryer.. The surface must be heated and slowly remove the old coating from it. In this process, the main thing is temperature control: you should not bring wood to overheating, because it can be charred.

The third method (mechanical impact) involves the use of a grinding machine and sandpaper. Usually this method is used for large areas. After the surface sanding work is completed, a primer and varnish should be used.

To learn how to varnish a tree, see the following video.