Features of acrylic lacquer for wood

If you decide to cover the wooden base with varnish, it is not easy to choose a suitable composition. In a variety of wood coatings it is easy to get lost. And although they are all designed for the same material, the properties may be different. What are the advantages of acrylic varnishes for wood, when it is better to use them: we understand together.

Special features

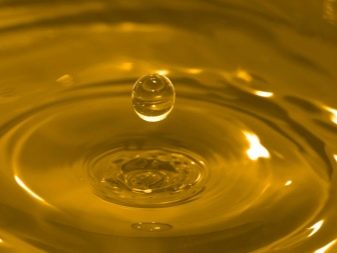

More recently, compositions for the treatment of wooden foundations were limited to various stains. Now the production of paint and varnish materials has stepped forward. Appeared materials with high performance and protective properties. Acrylic varnish is becoming increasingly popular among consumers.It consists of water, binding components and various additives.

Manufacturing technology uncomplicated. The components are added to water and mixed to a uniform consistency. Solvents are added to the mixture to form a characteristic film for which acrylic lacquers are valued.

To improve the quality characteristics in the composition of the varnish include acrylic dispersion, antiseptics (to combat microorganisms), plasticizing agents that make the composition elastic and easy to apply.

Advantages and disadvantages

The use of acrylic varnish for wood has several advantages.

- Moisture protection. Formed on the surface of the film does not allow moisture vapor to penetrate into the wood.

- Sun protection. The treated wood will have a beautiful shine and natural shade for a long time.

- Thanks to antiseptic additives, the base will be permanent protected from rotting and mildew.

- Giving strength. All small cracks and voids will be filled with varnish, the performance of the wooden base will increase.

- Acrylic varnish film layer protects against minor mechanical defects and chips due to its plasticity.

- Economical expense. The layer is quite thin, which is beneficial when processing large areas.

- Increased fire safety and environmental friendliness. The varnish does not emit toxic substances and unpleasant odors. Therefore, acrylic-based lacquers are best suited for treating internal surfaces.

Among the disadvantages, there is one feature: the film layer prevents the natural air exchange. As a result, with sharp fluctuations in temperature and changes in humidity, wood begins to expand and contract. LKM are elastic, but over time are deformed.

We have to restore some parts of the coating or completely repaint.

Application

Due to the good protective properties, environmental friendliness and decoration, several applications of acrylic paint and varnish compositions can be distinguished.

Finishing external and internal surfaces

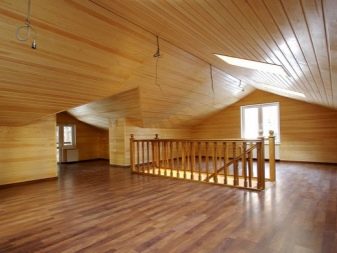

If you want wooden walls and finishes in your home, garage, homestead structures, gazebos, on the balcony and inside the apartment, they keep a pleasant appearance for a long time and are not moldy, acrylic lacquer is your choice. The surfaces will be covered with a glossy or matte layer, emphasizing the structure of natural wood, its natural shade.LKM is used in institutions where there is a large number of people (shopping and entertainment areas, gardens, schools and other educational institutions).

Decorative processing of interior elements

Many craftsmen create real masterpieces for home decor made of wood and varnish them. These varnishes can cover furniture, statues, columns, arches, gratings, hangers, partitions. Often they are treated with stairs and railings.

Kinds

Water-based acrylic lacquers have several varieties depending on the number of components.

Single component

In this case, only acrylic is added. The convenience of these products lies in the fact that they sell them ready-made mixtures. After acquiring the varnish can be immediately applied to the surface. Depending on the required thickness, you can cover the tree in several layers. The advantage of such materials is the fact that they cover the base well and dry quickly.

If necessary, they can be sanded with various abrasive tools. Apply paintwork using compressor spray.

It is better to use professional tools to obtain a uniform solid layer.After finding the final state, the lacquer turns into a persistent barrier to impact on the tree aggressive environment.

It is advised to apply them in a single dense thick layer due to quick drying. So they form a uniform smooth surface and well distributed. It is better to use them for finishing the internal elements of structures.

Bicomponent

Since the ingredients are sold in the form of a dry powder, it is better to use a two-component look only in professional construction, observing the necessary proportions for distribution. For application, it is convenient to use a spray gun, since the final product has a sufficiently liquid consistency with the smallest particles. Acrylic and polyurethane are used as binders.

The advantages of the coating are non-susceptibility to inorganic solvents, resistance to wear, damage and abrasion.

This type of varnish can be used for outdoor work. The choice may lean towards alkyd varnishes, but acrylic is more environmentally friendly.

Different types of paintwork materials give the possibility of some variations in the decoration of wooden elements. Glossy texture has a pronounced brilliance.Semi-matt varnish has a small overflow, not irritating the eyes. Matte texture has no reflectivity. Varieties of textures do not differ in performance, you can choose any convenient format.

Color spectrum

Acrylic formulations usually have a clear color. This is a definite advantage for those who want to emphasize the beauty of the natural shade of wood. Colorless composition will add the desired degree of gloss. If you want to give the surface a radically different shade, varnish can be combined with water-soluble paints. When mixing, you can get any color: beige, white, black, red or a light sheen of the selected shade. The choice is made on the basis of stylistics, adjusting the tone, taking into account the overall design concept.

Manufacturers

Many companies in Russia and abroad produce acrylic varnishes. In today's market, customers are offered products of different brands. Below are the most famous of them.

"Chief Technologist"

The line of LKM "Chief Technologist" is issued by the enterprise from "Novbytkhim". A significant advantage of the manufacturer is the presence of its own research laboratory.Acrylic lacquer for wood is suitable for indoor processing, outdoor work in conditions of the average Russian climate. They can cover the already painted surfaces with water-soluble paints.

Dries the coating for 2 hours at room temperature and normal humidity (40-60%), consumed economically. Manufacturers recommend using paintwork materials at temperatures above 10 C. After applying each layer, you must give the previous one to dry for an hour. In the closed state of the composition is stored up to two years. Varnish is produced in buckets by packing 0.5, 1, 2 and 10 kg. The color scale is presented by 12 shades of the most demanded tree species (maple, beech, pine and others).

VGT

Good customer feedback is received by VGT products. Two plants have their own laboratory and are engaged in the production of a wide range of materials. VGT Varnish is designed for antiseptic surface treatment. Due to its composition, it penetrates deep inside the base, ensuring the safety of the surface. Lay down a thin layer in the form of an elastic film.

It can be applied with any tools, it differs in a small consumption (from 100 to 160 g / sq. M).Adhere layer ceases within 1 hour. Full drying occurs after 2 days. The composition is presented in 12 shades. It is recommended to apply it at a temperature of 7 degrees C and above, as well as sufficient air humidity. Stored in normal conditions for 24 months. Available in formats of 0.9, 2.2 and 9 kg.

Tikkurila

Tikkurila is a well-known Finnish brand with a century and a half history. Since 1995, the company has been operating in Russia. The products have long gained popularity in the Russian and world market of paints and varnishes. Finnish quality makes Tikkurila lacquers in demand in the construction market. Acrylic compositions are available in several versions.

There are glossy, matte, semi-gloss textures. Varieties have good protective properties, they are perfectly aligned when applied. Material consumption is moderate: from 8 to 14 square meters. m / l Fully varnish brand dries in 24 hours. On the shelves of stores sold in cans of 0.9, 2.7 and 9 liters. The only disadvantage of this product is the high price.

Lacra

The Lakra group of companies is one of the leaders in Russian production of acrylic varnishesDue to the production of products in many European countries, its quality meets the highest standards. These compositions are applied with a brush or spray gun, they have a small flow rate (from 8 to 14 sq. M / kg). The range includes all options of textures, products have an attractive price and are sold in two versions: 2.5 and 10 kg.

The pressurized product is stored for up to two years. Dries after application after 5 hours, the hardness becomes even after 3 hours. The surface is completely ready for operation in 7 days. Paintwork companies have good performance.

Eurotex

Acrylic varnish for wood Eurotex is a product of the Russian brand. It guarantees the protection of the array from various kinds of microorganisms, moisture and temperature fluctuations. These products can be used for outdoor and indoor use. Prepack paintwork in packs of 0.9, 2.5 and 9 kg. Acrylic varnish of the brand is economically consumed: 1 kg is enough for processing 20 square meters. m surface.

The company's products receive a lot of positive feedback from buyers and craftsmen. Among other comments, the durability of the applied layer is noted.

Pinotex

Pinotex products are used for internal and external wood surfaces. Sold material in containers weighing 1, 3 and 10 kg. The acrylic composition is consumed economically: it can cover up to 18 square meters. m basis of one kg of the mixture. The manufacturer focuses on the high environmental friendliness of the product, its safety, which is reflected in a rather high cost. Glossy lacquer has antiseptic additives, is eco-friendly and is easy to apply with the help of any types of tools from the spray gun to the brush. Products are constantly being improved, improve technological characteristics.

Tips

For the successful implementation of finishing work is better to perform basic recommendations.

- Before applying paint on the surface, you need to mix the varnish to get rid of lumps and clots.

- If in the course of work the varnish has thickened, it can be diluted with water. Solvents cannot be used.

- In order not to spoil the object, try to first apply the varnish in an inconspicuous place.

- Acrylic composition dries evenly and qualitatively if there are no drafts and no open sun in the room.

- It is recommended to cover the wooden surface in several layers.So that as a result the coating does not have defects, the penultimate layer can be sanded.

- To dry the surface, you need up to 12 hours. After that drawing the next layer is possible.

- When working with dry areas, hard and sharp shoes need to be removed, it is necessary to put soft supports under the furniture.

- If you work in conditions of high humidity or low temperature, the drying time will increase.

Acrylic-based varnish can be applied to painted substrates if water-based paints have been used before.

In the next video, see the review of universal acrylic lacquer on Ticiana wood.