Kitchen table do it yourself

The role of the kitchen table in everyday life is difficult to overestimate. It is considered to be the main attribute in the kitchen, and not without reason - after all, the whole family often gathers at the table, noting various events taking place in life.

Speaking about the kitchen tables, in the mind most often there is a dining table. However, kitchen tables are used not only for a feast and differ in their functions. So, the bar table perfectly divides the space into zones. It can be used as a dining for a small number of people, as a rule, it is 2-3 people. It is especially relevant when you need to save space. The table under the sink is the basis for embedding the sink.

Thinking about purchasing a kitchen table, you can consider the possibility of making it yourself. This option, firstly, will save some amount of money. Secondly, to surprise the guests with the original shape of the product, unusual design or method of decoration.Third, master the skills of joinery. And, of course, enjoy the work done and the final result.

Convinced of the need to manufacture the kitchen table yourself, you need to determine for yourself a number of important parameters. Namely, it will decide what form it will be, choose the version, calculate the dimensions of the product and the size of individual parts, decide on the material for their manufacture.

About how to make a table with your own hands, you will learn in the video:

Kinds

Tables differ on execution options: classical, folding, a transformer, angular, folding or suspended, sliding. At will and need the table can be with a curbstone or with boxes. The choice of options depends primarily on the size of the kitchen and semantic load.

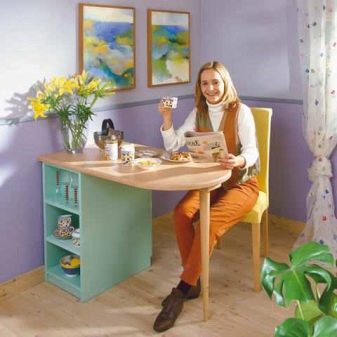

For small kitchens, the most likely ideal solution would be a folding option, either folding, bar, corner. Corner tables can also be foldable or foldable.

Transforming tables solve the problem when you need a 2 in 1 solution, which greatly expands the possibilities of its use. So, with a flick of the wrist, an elegant coffee table can easily turn into a full-fledged dining table.

A retractable table saves space and is built, as a rule, in kitchen sets.

With the help of a bar table you can divide a room into zones of both a small square and a large one.

Materials

The materials from which you can make a table are striking in their diversity and require a clear idea about yourself.

For this purpose, suitable arrays of various tree species, such as oak, coniferous trees. If a beginner is going to be engaged in production, then pine will be perfect, as it is much easier to process it. Furniture made of solid wood is considered "capricious" and requires special treatment. It can fade under direct sunlight, absorb odors, it is badly affected by changes in humidity and temperature. The positive aspects of this material is environmental friendliness, durability. Furniture made of solid wood looks very elegant and expensive.

- Chipboard - material, fairly common and very often used for the manufacture of furniture. It is made from dry chips and resin by pressing. Among the minuses can be identified environmental insecurity. Plus - relatively inexpensive cost.

- MDF It is considered more environmentally friendly material compared to chipboard, but is also more expensive.It is obtained as a result of mixing wood chips with carbide resins modified with melamine and their pressing. The minus is highly flammable, and even quickly heated objects, not to mention an open fire, present a potential risk of ignition.

- An alternative to particleboard and MDF can be furniture board. It has a relatively inexpensive cost. It is a strong and environmentally friendly material. It is a glued bars, strapped by the press.

- Metal can also be used to make a table. Most often for these purposes use stainless steel. The cost of such material is quite high, and the cold surface will require the use of tablecloths or napkins. However, the sparkling appearance of such an attribute is sure to attract everyone’s attention.

Dimensions and shape

The most common form is rectangular. A rectangular table is convenient because it can accommodate a sufficiently large number of people, while requiring less useful space for itself than a round one. It can easily move to the wall. But due to sharp angles, both rectangular and square variants are considered the most dangerous.

Round - claims to be a usable area 1.5-2 times as large as the area needed for a rectangular table designed for the same number of people. It is believed that the round table is stronger than other forms create a feeling of comfort in the room.

Oval tables, as well as rectangular with rounded corners, combine the advantages of rectangular and oval shapes. Oval tables are considered the most elegant and aristocratic.

Dimensions can vary from large to compact. If necessary, the design of the compact table can be designed in such a way that it can be increased. For example, a folding table in a folded state takes up little space, when unfolded, it can accommodate a sufficiently large number of people.

The important point is the calculation of dimensions. When it comes to a standard kitchen, ranging in size from 6 to 8 square meters, the drawings and diagrams will demonstrate a standard solution with a height of 750 mm, a length and a width of 800 * 500 mm to 1200 * 600 mm, respectively.

For correct calculation, the number of persons must be multiplied by 60 (perimeter per person).But as far as width is concerned, the width from 800 to 1200 mm is optimal here. Because narrow tables are difficult to serve, and it’s not very comfortable to sit at wide ones. For a round table, you need to measure the circumference by the formula - diameter * 3.14 (pi).

Step-by-step instruction

- If you intend to make this kitchen attribute yourself, you must make a drawing.

- To make a table from solid wood you will need the following tools: a plane, a grinder or a grinder, an electric jigsaw, a circular saw, a drill (with a 6-8 mm drill), a screwdriver, sandpaper, self-tapping screws (30-35 mm), joiner's glue, dowels, clamps, pencil, tape measure, gloves and safety glasses.

- You need to buy supports (legs) for the table, which can be different - from the usual rectangular to figured.

- For a worktop 80 cm wide, four planks 120 centimeters long will be required. They must be dry.

- For smoothness, the worktop must be well sanded. Joints should be machined in such a way as to achieve full contact with each other.

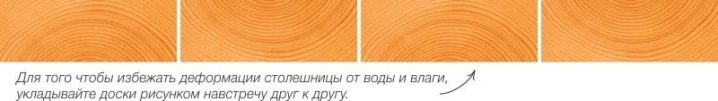

- In order to avoid deformation of the tabletop from excessive moisture, lay the boards need to be patterned towards each other. To connect the boards need shkanty.

- At the ends of the boards, which will be connected, make holes with a drill of 8 cm. The distance of the holes from each other should be 10-15 cm. Then these places should be sanded and smeared with glue on the end, holes and shkanty. Dowels driven into the holes and thus connect the countertop. Excess glue needs to be removed.

- Using screws and glue it is necessary to connect the transverse and longitudinal boards with legs. In the longitudinal planks above we make two holes, they will be useful for fixing the table top. Wait 12 hours. Install countertop.

To finish the finished product with varnish, paint or stain. When using the stain, it is necessary to take into account some nuances - to choose a thinner (if there is not enough experience you need to use a slow diluent), the surface to be treated should be evenly polished, it is important to correctly adjust the gun (the torch should be oval and the applied layer should be half covered).

Traditionally, for the manufacture of wooden furniture use dowels. Such a connection is not visible and has a low cost.

For wooden tables it is appropriate to use wooden dowels,since they shrink at the same time in such a case. For particleboard it is better to use plastic, since particleboard practically does not shrink.

But inexperienced craftsmen find it difficult to achieve the most accurate calculation when planning openings for dowels. Therefore, an alternative to them are euro screws or confirmatics. Of course, this somewhat increases the cost of the product, but makes it easier to manufacture.

A kitchen table made of laminated chipboard with metal legs can be quite a budget solution.

- Chipboard sheet at the present time, you can easily buy the right size, or cut it yourself. The most common, top coating of plastic makes the tabletop sufficiently resistant to abrasion.

- For work you will need: an edge for machining the butt, ties, connecting and end strips, designed to protect the joints and ends of the tabletop from moisture, dirt, grease. In addition, make the appearance more aesthetic. For the manufacture of such a table is also necessary to purchase the legs.

- On a sheet of chipboard note the desired radius of curvature. Next, cut the tabletop in a given shape with an electric jigsaw.To prevent chipping of the plastic surface, it is better to work with a saw with reversible teeth. Using the router, make a groove and fill the edge.

- Be sure to lay the sealant in the edging, and in the upper side of the tabletop. Remove excess sealant. There is a special solvent designed to clean surfaces of similar materials. Using self-tapping screws, install the holders and put the feet on them.

It should be noted that to make such a table can be quite easily and quickly.

The following method allows not only to assemble a modern model of a wooden table without enormous costs, but also to redo the old countertop.

- This will require unnecessary boards of the same size, glue for joinery and three clamps.

- Boards must be laid out on a work surface so that the middle of the laid board is at the junction of the two previous ones.

- With the help of wood glue and clamps need to fasten the boards together. Then align the edges and sand the surface. Sand the edges and cuts.

- If the table is made entirely, then for the manufacture of legs will require two boards and a corner that will connect them together, as well as carpenter's glue.

- First we glue them together with glue, then we fix them with a corner.

- Along the perimeter, on the inner side, where the legs are connected to the table top, we attach a bezel.

- Fasten the table top, legs and bezel need with a corner.

- Varnish the surface.

- To make or restore the table, you can use wooden pallets.

- To do this, we make the basis of the tabletop and attach the support. For strength you can come to the legs of the wooden struts.

- It is better to install the wheels, since the tabletop will be quite mobile.

- Fit a piece of plywood to the desired size and attach a bezel around the perimeter.

- We lay a piece of plywood on the base.

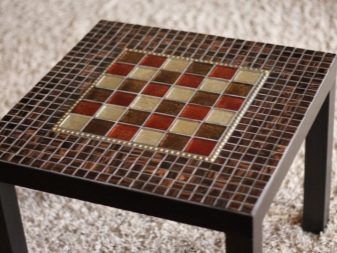

For decorating the countertops, you can use crushed ceramic tiles or a mirror. Glue them to the tabletop, fill the voids with grout for joints. At the finishing stage, you can paint or varnish everything. This method can also be used for the restoration of a damaged or old tabletop.

Examples of interesting design

There are many more interesting ways to decorate tabletops. One of which is staining through tulle. The result of this decoration is a beautiful lace pattern.

If you want to decorate the countertop "semi-antique". You can make craquelure - drawing on the surface of cracking varnish, giving it the appearance of old paintings.

Decorating with epoxy will help to achieve the effect of "ice" countertops. Epoxy resin is a liquid that resembles glue, which, upon contact with air, hardens and turns into a transparent plastic. As decorations, you can use dried flowers, shells, stones, beads, placing them inside the solution. If you add a fluorescent powder to the epoxy resin and fill it with cracks on the countertops with this solution, you will get a very interesting result. In this case, the color of the fluorescent powder can be chosen, for example, so that it is in harmony with the color of the dish.

An original idea looks to decorate a depression in the tabletop with various decorations, for example, shells, and cover it with transparent glass on top.

Simple and interesting to update the table, you can use color tape.

Nobody will be indifferent to the drawing, laid out using mosaic.

Even a beginner can update the table using the decoupage technique, and even ordinary napkins with pictures or images from magazines can serve as a basis.

The surface of the table can be decorated with painting.Painting is a delicate matter that requires skill, therefore, not possessing such, it is probably better to call the artist. For painting mostly suitable wooden table.

Also drawing paint can be done using stencils.

A self-adhesive film is considered a fast design method. It is worth noting, a hundred film with the image of food excites the appetite. You can also find a film that imitates wood. This way you can easily create the desired design. And the most pleasant way to decorate a table is lovingly prepared dishes.