Installing gas lift to the kitchen cupboard

What it is?

Kitchen gas lift is a shock-absorbing mechanism for doors of horizontal opening. The mechanism "gas lift" refers to a large group of brackets. It has the appearance of a lifting mechanism, the main purpose of which lies in opening and holding doors. Due to this, the doors open and close without any extra effort. In addition, opening the door completely, the door provides the ability to fully see the contents of the cabinet.

Gas lift is known as an absolutely sealed construction. Nitrogen enters the cylinder during the production process, and in case of damage it cannot be repaired.

The main advantages

- Smooth ride with self-regulation;

- Securely fixed in the “open” position;

- Two types of opening - stepping (friction) and automatic;

- The fasteners of gas lifts are similar to the material from which the furniture is made (chipboard or aluminum);

- It is possible to open the door with no handle.

Design

The gas lift is made of several plastic and metal parts: a button, an external cone, a gas valve, a plastic sleeve, an external cavity, a gas-lift cone, a gas bypass channel, an internal cavity, an internal cone, a sealing element, a lifting rod, a thrust bearing, a landing cone.

How to install?

Proper installation of the gas lift on the cabinets should begin with the preparation of tools and drawing markup for a more precise attachment.

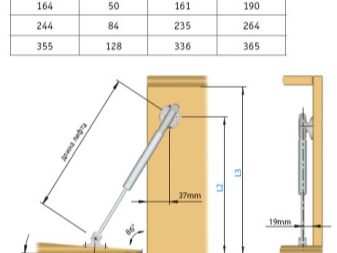

Selection of gas lift for the kitchen cabinet is determined by two important indicators: the device parameters and the force of compression of the spring. First of all, it is necessary to install the device, according to the dimensions corresponding to the size of the cabinet. To do this, it is necessary to measure the height of the door and the depth of the cabinet and, according to the values obtained, select a standard gas lift. Usually you have to choose from three standard sizes: these are 164, 244 and 355 in the extended state. In addition, it is imperative to check the following dimensions of gas lift: the length in the folded state with and without fasteners, as well as the maximum length of the stem extension.

An important indicator for reliable fixation of the door in the open state iscompressive force. This value is normalized and is mandatory indicated in the passport and on the mechanism case. For an unmistakable choice of gas lift, it is necessary to determine the mass of the door with regard to all fittings, coatings and decor. According to the standard furniture gas lifts are available on the force of 60, 80, 100, 120 and 140 Newtons. Calculation at the choice is made from a condition: 1 kg on 10 newtons.

When choosing equipment, you should consider the system of fastening the mechanism to the furniture surface. The most common fasteners are flat pads that allow installation on the sides of the cabinet and the door using screws. If the cabinet body is made of wood, it is possible to use fasteners in the form of a twisting element.

Instruments

In order to install gas lift on the kitchen cabinet, you need to equip a whole set of tools.

- Screwdriver;

- Screwdriver;

- Pliers;

- Hammer;

- Electric drill;

- Ruler;

- Roulette.

Cabinet Layout

The figure shows a schematic illustration of the installation and the table of correspondence of the installation dimensions. This shows the installation mechanism when opening the door down.Installation of the rising door is done in exactly the same way. First of all, the compliance of the selected equipment is checked: for a wall-mounted cabinet with an internal cavity height of 365mm, a gas lift with a size of 355mm is required.

The layout of the cabinet is made in the following order. First, the label of the center of attachment is placed on the side: for this, a height L2 of 366 mm is measured from the inner surface of the top cover, and 37 mm is measured from the front edge of the side. Then the center of fastening on the door is marked: for this, the length L1 from its upper cut is measured equal to 128 mm, and the distance equal to the full height of mounting on the side of the cabinet (from the side of the side panel to the center of the elevator ball joint) is measured - usually 19 mm. This marking is done from two sides of the wall cabinet.

Installation

The installation of equipment begins with the fixing of the mounting base to the side of the cabinet at the marking site. Two methods are most often used - a bracket with a spring and a plate. The staple is usually screwed into the sidewall material at the marked point, and the lift head simply clicks into place.

If the base of the mount has the form of a plate with a hole, then it is mounted on 3 or 4 screws to the sidewall so that the center of the hole coincides with the marked point.The hinged lift head is inserted into this hole and fixed. In this case, it is important that the base plate is not deformed - when curved, the elevator will not work.

Exactly the same steps to install the device mounting base are made on the inner surface of the door. It is important to provide an inclined angle of the hinge, which should be about 8 degrees.

Useful tips

- In order to avoid distortions, the mechanisms must be fastened on both sides;

- The door must additionally be attached to the top cover of the cabinet with the help of two furniture hinges of the dish-shaped type;

- Lifts with a loading pressure greater than 80 newton are used very rarely and only for very heavy doors;

- Installation of the mechanism is made after installation on the door of all necessary accessories, cladding and decor;

- Installation of equipment should be made on the cabinet, removed from the wall;

- Increasing the opening angle of the door can be achieved by moving the mounting point closer to the front edge of the sidewall;

- During the installation of automatic mechanisms it is necessary to strictly follow the installation instructions.