Kitchen Cabinets

Kinds

When buying a kitchen set it is necessary to pay attention not only to the beauty of the facades and the functionality of the drawers. Today, a mandatory requirement for high-quality kitchen furniture is staffing with sturdy fittings and mechanisms. After all, thanks to the reliability of mechanisms for kitchen cabinets, the furniture will last a long time, storing kitchen utensils in cabinets will become orderly and ergonomic. The kitchen will be neat and convenient for cooking.

Furniture hinges are important components for any kitchen furniture that has opening doors. The range of them for different needs is quite diverse. Particularly popular in the manufacture of most modern kitchens are systems with comfortable and durable closers.

The closer is a compact device specially mounted on the cabinet doors for slow and smooth closing.Gradual and soft closure prevents the formation of chips of the paint layer and cracks, which increases the life of the door and the kitchen cabinet as a whole.

Closers must keep the kitchen cabinet doors closed. However, they do not guarantee the possibility of a sharp slam of the door with careless closing. If there is a glass shelf in the cabinet or fragile dishes are standing, damage cannot be avoided.

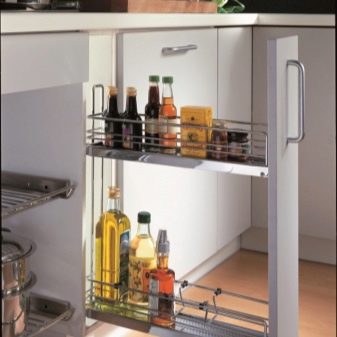

Door closers used on door hinges are not suitable for withdrawable shelves, drawers and other items. In such constructions special types of closers are used, having visually invisible special guides. Retractable door closers are more expensive than looped, but their price is justified by the reliability and comfort of use.

For the organization of optimal storage in hard-to-reach corner kitchen cabinets, rotary mechanisms are mounted that push the shelves and bottoms of storage systems when opening the door and return the entire structure back when closed.

Lifting mechanisms are also useful devices in the manufacture of kitchen furniture. Ordinary kitchen drawers can be opened by opening the doors or tilting down parallel to the floor, which is not always convenient in conditions of limited kitchen space.

In modern kitchen sets, today convenient doors opening upwards are used. For such cabinets and need lifting mechanisms with closers, carrying out a smooth opening to the desired height. Opening doors and taking items from the shelves of such cabinets becomes more convenient process, it is not necessary to fix the handles, lifting is done by gently pressing the door surface with your hand.

Structure and principle of operation

Mechanisms closers are conventionally divided into oil and gas. Inside the oil mechanism is an oil-filled capsule complete with a working spring. The principle of operation of the oil mechanism of the closer is as follows. In the process of closing the door begins to put pressure on the stop closer. The oil covering the spring flows to the back of the capsule, where it is held using a stuffing box system. The speed of closing the door can be controlled by adjusting the special valve, which narrows and expands the oil outflow channel.

Closers of the oil group, produced in a wide range by Russian and European manufacturers, have received great recognition from consumers.The price range allows you to pick them up for any wallet.

The work of gas closers is similar to the work of oil devices due to changes in air pressure in the capsule. The cabinet door closes to a certain point, at the end of the closure it affects the closer, which smoothly completes the closing process. The disadvantage of the gas structure is rather rapid wear, since in the closed state of the door a strong load on the mechanism of the door closer.

Advantages can be called a more affordable price compared to the price of oil construction, as well as the exception in case of breakage of oil on the surface of furniture.

A common drawback of spring mechanisms is the impossibility of leaving the door in a half-open state. Therefore, spring designs of closers are installed, as a rule, on inexpensive kitchen furniture.

Today, manufacturers offer reliable brackets of modern design, allowing to leave the doors in a semi-open state, adjusting the opening at an angle of more than one hundred degrees. It is becoming increasingly popular to move the doors up and down mechanisms with electric drive.Such lifting devices are used in "smart kitchens".

Selection

In our time, the mechanisms used in the installation of furniture for the kitchen, are produced by many European and Russian manufacturers and meet strict quality criteria. Choosing products from well-known manufacturers with extensive experience of their own developments, the consumer receives reliable products that will last more than a dozen years.

The strength characteristics of each product declared by the manufacturer must be confirmed during load testing. The use of strong closing and withdrawable mechanisms for the upper compartments and floor cabinets of the kitchen set allows you to store a large amount of dishes and products longer.

The use of metal with multi-layer chrome plating not only protects the mechanisms from corrosion and other damage, but also gives an aesthetic and stylish look to the kitchen space.

Pull-out drawers and baskets mechanisms, rotating corner storage mechanisms, equipped with closers should be securely fastened and ensure completely silent operation of kitchen cabinets.

How to install

When purchasing a kitchen set, of course, you need to give preference to a model with pre-installed closers. If necessary, with the installation of closers to handle and master with little experience. It is only necessary, after consulting with the seller, to select the appropriate mechanisms, furniture fasteners (screws, euro screws), a screwdriver, a hammer, a pencil and read the instructions.

Proper installation of the furniture closer is a guarantee of its long-term and convenient operation. Closers can be attached directly to the cabinet body. In the store of goods for repair, you can choose easy-to-install reliable loopback gas closers. After fixing the hinge into a special hole, you need to insert a closer to click.

Installation of the sliding closer on a box of a kitchen cabinet also will not take a lot of time. First, fasten long guide rails. Then the main part of the mechanism is fastened on the box with self-tapping screws. Putting the box in place, it is necessary to check the smoothness of the sliding structure on the rails.

When mounting massive kitchen doors, the main piston part of the closer is fixed on the fixed shelf, and the rest is fixed on the door. On the case of furniture closers fasten with screws.

After installation of the mechanisms, it is necessary to carefully adjust with the screw on the case. From the correct adjustment depends on the sliding speed of the sliding system, the opening speed and tightness of the cabinet door.

Furniture closers are fairly simple mechanisms, so their damage almost never happens. In the process of daily use of kitchen cabinets, it is necessary to periodically lubricate the mechanisms of the closers, to clean them of contamination using napkins moistened with soapy water. It is not allowed to handle the mechanisms of closers with cleaning powders containing abrasive particles.