Sofa in the kitchen with their own hands

Sofa - a convenient and very comfortable type of furniture. Perhaps that is why he was very popular. Now in furniture stores there are many varieties and models, but, unfortunately, it is not always possible to find exactly what you want to buy and what will best fit into the image of your interior. It is also not always possible to find a suitable ratio of price, quality and design. In this regard, there is a desire to make a sofa in the kitchen on their own, focusing on the style and design in which the rest of the kitchen is already made.

At first glance, the idea seems to be not only not very feasible, but even an impossible dream. However, you should pay attention to the fact that its implementation does not require any specific materials, accessories and tools.

As soon as you manage to understand this, worldly intelligence, knowledge and skill come to the rescue,in this case, it is enough to enlist the support of knowledge and, as a result, to get the subject of our unquestionable pride - the kitchen sofa of your dreams. An important advantage will be that you will know with absolute certainty all the materials from which it is made, and you will be able to choose exactly the functionality that you need. It is also worth noting that the financial side of the issue in this case also remains to be won, since the costs will be commensurately less relative to the options that can be purchased in the store.

Where to begin

First of all, you should decide on the appearance of the sofa that you would like to receive as a result. You should not overly complicate the design and introduce complex creative elements into it, because at home, not everything can be done at the proper level. It is worth staying at a simple, but convenient option that will delight you and your guests.

A standard sofa should have a frame resting on the legs, you can also use roller mechanisms. The design with folding seats give access to niches that can be used as drawers.At the same stage, you need to decide how soft the sofa you want, what should be the colors and material of the upholstery in order to make it easy to clean later.

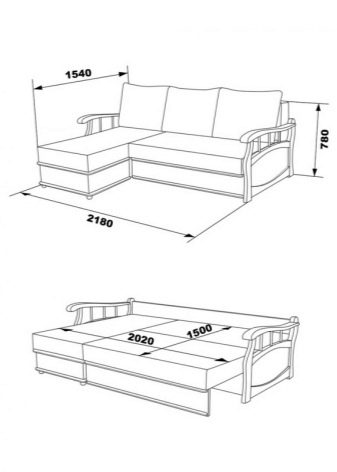

Very carefully, you need to consider planning the size of the future sofa, as the dimensions must be commensurate with the space that it should take. All measurements should be made in advance and a drawing for the manufacture of furniture should be prepared.

If this is your first experiment in making furniture at home, then it is worthwhile to dwell on a folding option, and not on making a corner. The rectangular shape of the sofa with legs is much easier to make, and it is much more difficult to make a mistake in calculating the size.

The frame can be made of timber, for this purpose, better fit pine trees, which are fastened with screws. To avoid the formation of longitudinal cracks, it is necessary to have fasteners at different levels. To make the construction as strong as possible, the bars should be screwed to the corners of the frames, which have a cubic shape.

Screws will act as fasteners, since it is most convenient for them to fix the wooden structure. The bottom of the sofa, like the seat covers, is better to make from plywood.

Frame materials

For the manufacture of the sofa does not require any specific materials, you can do with ordinary bars and plywood sheets. As a decor and as the closing elements it is possible to use the laminated wood chipboard (LDSP). Chipboard can be selected in the color of the kitchen facades, then you can get a single ensemble.

It is worth starting with the development of a drawing and a project, which takes into account all the details and dimensions, the angle of inclination of the back, the height of the legs, as well as the overall dimensions of the structure. The main load will fall on the legs and back, it is worth considering and make the foundation more durable. For work it is better to choose a timber with a size of small cross section of 60x60 mm, and plywood sheets should be waterproof with a thickness of 12 mm. These materials are running and can easily be found in the building stores of your city at fairly reasonable prices. Screws and steel corners should be used as fasteners to make the structure stiff. For work, you will also need a saw and a screwdriver.

Upholstery materials

Upholstery should be made using foam rubber, padding polyester and upholstery fabric.The thickness of the material should be calculated from the fact that when using 5 cm foam rubber seat you get a semi-rigid. When choosing a fabric it is worth paying attention to the fact that we are assembling a sofa for the kitchen, so the material should tolerate frequent cleaning and washing. However, there is another option, it is to make additional covers with zippers, which can be removed if necessary, in which case they will be conveniently washed in a washing machine.

Also, the idea with covers can be used in the future to update the interior, the more it is much less troublesome than to start hauling the entire sofa. All wooden elements should be sanded and varnished or varnished if you want to keep the texture of the wood or paint it in a suitable color.

Step by step assembly instructions

- It is worth starting with the preparation of the frame elements. Using tools to make the cut bars in accordance with the drawings. At this stage it is necessary to process all visible parts with stain or paint of your choice.

- The formation of the frame is made with screws, for a stronger connection, you can use glue for wood, it is non-toxic and is well suited for the pine species chosen by us.

- Having made the frame, you can proceed to the installation of the backrest structure. For fixing, you can use metal corners. It is also worth remembering that the vertical position of the back is undesirable because it is not ergonomic.

- The seat should be made of plywood sheets, from which the appropriate size of the cover is cut. If the free space under the sofa is planned to be used for storage purposes, then you should think about the possibility of free access to it. Covers can be fixed with the help of hinges, in this case they will recline to the side convenient for you, but at the same time they will remain fixed.

- The bench and backrest should be made of soft materials that can maintain their own shape and, during operation, will not slam and deform. The best choice is the choice of foam or its analogue of polyurethane foam, you can also use a synthetic winterizer. These materials have elasticity, flexibility, and the last of them, among other things, is not as hygroscopic as the others, which is of no small importance for the kitchen. In order to obtain the best result, you can combine materials at your discretion.In order to fix the filler, you can use glue, it will prevent slipping.

- If your design implies the presence of armrests, that is to cover up with soft materials and them.

- For skin suitable leather, leather or tapestry. Here you are limited by your imagination and financial side of the issue. The material is pre-cut, the edges should be processed to prevent shedding and spreading of the fabric. Raskruennye plating elements attached to the structure with a construction stapler or staples can be hammered with a hammer. First, it is necessary to sand all wooden surfaces and corners that will come into contact with the fabric in order to avoid abrasion and to prevent breaks in the future.

The process of covering is not anything complicated, you can even do without the help of others, the main thing is to be careful, not to rush and follow all safety measures. It should be remembered that if you stretch the fabric too much, it will wear out faster, and if the tension is insufficient, the appearance will suffer.

Calm and knowledge is your key to success.

In the manufacture of furniture, the main thing is patience, calm and knowledge.If you are not in a hurry, at the first stages you will thoroughly work out the scheme of the sofa and make its drawing with all sizes, then at the stage of cutting and assembling the structure there will be no problems. But everything is too early, it is worth being prepared for the difficulties in the process, especially if you are doing it for the first time. They should be treated as a normal working moment, do not panic and be upset if something went wrong as you wanted. We need to stop and think about how to fix this situation. You always have the opportunity to change everything and redo it, because that's the advantage of making a sofa with your own hands, that you can change all the flaws and shortcomings in the work at any moment.