Paint remover for metal: types and principle of operation

Sometimes it is required to remove paint from metal surfaces. There are several ways to remove old paint.

Special features

There are three ways to remove old paint from a metal surface:

- Mechanical - processing is performed by sandblasting machine or manually using emery paper. May cause metal damage.

- Burning out - heating the metal to high temperatures, due to which the paint itself lags behind. This method entails the risk of fire and surface damage.

- Chemical - the use of special compounds that corrode the paint in a short period of time.

The chemical method of removing the old coating is the most sought after and commonbecause the cleaning compositions destroy only the paint without affecting the surface itself. The compositions are easy to use and presented in a wide range.

Advantages and disadvantages

Chemical removers of old paint have many advantages over other cleaning methods. These include the resistance of the surface to the effects of chemicals in their composition (as opposed to mechanical cleaning methods) and ease of application and cleaning of paint and varnish products.

Paint strippers act fairly quickly. It depends on the type of cleaner, the number of layers of the old coating and the air temperature. On average, the dissolution of one layer takes from 20 minutes to 2 hours. To remove dissolved old paint there is no need to exert great effort - the old coating is easily removed with a spatula.

Often the flushing agent (remover) dissolves not only unnecessary coating, but also cleans the metal from corrosion, which saves time and eliminates additional actions.

Cons of metal washes:

- With a large thickness of paint is necessary to apply several times a means to remove it.

- Sometimes after using the remover, greasy stains remain on the surface. This is due to the specific composition of the wash. To get rid of these stains, after cleaning the surface, it is necessary to treat it with a degreasing agent.

Operating principle

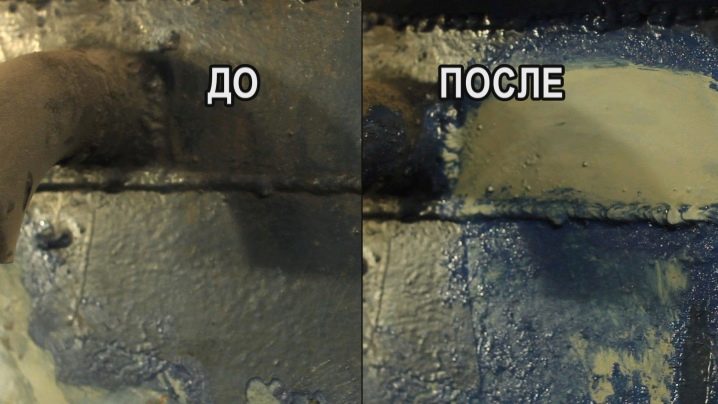

After applying the washing agent, after a while the paint softens, peels off and begins to swell. The coating loses its strength and density, the ability for adhesion is significantly reduced. This means that the solvent has worked.

After the time indicated on the tank with the remover will pass, you can proceed to removing the paint with a spatula. The coating is removed easily - under the influence of the flushing agent, it itself lags behind the surface.

Varieties and composition

Washes are divided according to the type of paint that must be removed:

- Universal - suitable for various surfaces: metal, concrete, wood. They have a high shelf life and can even dissolve powder coatings, but are useless for water-dispersion, acrylate and latex paints.

- For oil coatings. Composed of organic baking powder, thickener and solvent.Stir the mixture before use.

- For water-based coatings. The mixture is almost identical in composition with water dispersion eliminators. It is advisable not to purchase liquid with hydrochloric acid in the composition.

- Express washes. They have a fast exposure time - a few minutes are enough.

- For powder paints. Due to the high strength of powder coatings, stronger and more toxic washes are used.

Universal remedies have a lower price and are suitable for almost all types of paints, but it is recommended to use them in extreme cases, because often they do not immediately dissolve the coating, and thus their consumption increases.

Since the flushing fluid only works until complete evaporation, some wax or paraffin. These materials slow down the evaporation process, thereby improving the quality of the impact of the wash.. But they have a drawback: paraffin reduces the ability of the metal to adhere.

If you do not completely clear the surface of its traces, the new coating will not be able to gain a good hold on the surface.

Sometimes it is not enough just water and cleaning agent to remove paraffin or wax. In such cases, use acetone or other organic solvent. On the modern market, you can find washing means without paraffin, in their composition add more modern inhibitors of evaporation. Such agents do not require subsequent special cleaning of the surface.

By type of consistency, these types of washes are distinguished:

- liquid;

- in the form of a gel;

- sprays;

- water soluble powders;

- pasty.

Advantage gel solvents is the possibility of their application on a vertical surface and even on the ceiling due to their viscosity.

With sprays care must be taken: it is necessary to spray the composition at a distance of 25-30 cm from the surface and in a vertical position, at a great distance from sources of fire (they do not differ in fire resistance) and use closed clothes and safety glasses.

Spray removers well suited for profiled surfaces, because they penetrate perfectly into all the grooves that, for example, liquid solvent cannot cope with. Liquid formulations are best applied on level surfaces.

The coating remover can be applied with a brush if the surface has an uneven texture and fine details. For a large surface with a smooth texture, it is preferable to use a roller. Spray can be applied in a liquid state.

By types of components in the composition of the washing are divided into the following categories:

- acidic (hydrochloric acid is often present);

- alkaline;

- organic (characterized by the absence in the composition of alkalis and acids).

Basically for the metal are not terrible acid or alkali, but still for a successful result it is better to look closely to the washes with organic substances.

From the popular removers can be identified:

- Spray remover ABRO PR-600. It is safe and easily washed off with water, does not contain alkalis. Paint softening time is approximately 10-20 minutes. Suitable for washing acrylic, epoxy, polyurethane coatings.

- Wash "SP-7". The composition is based on organic ingredients, it is also safe. It is used to remove oil, acrylic, epoxy and alkyd coatings. This Russian-made remover has all the necessary advantages: fire resistance, rapid destruction of paint, penetration into the deep layers of the coating, removal of corrosive traces.It is applied both to horizontal, and to vertical surfaces.

Consumption

The amount of required liquid for removing paintwork coatings depends on the area of the treated surface, its condition (whether there are traces of corrosion), on the type of cleaning agent, the thickness of the old coating. The thicker the old paint, the greater the number of times it will be necessary to treat the metal surface with a wash, and therefore the consumption of funds will be more. Also for removing the oil paint will require more liquid than other types of paint.

The thickness of the washing agent layer must match the thickness of the coating layer.. Therefore, for an approximate calculation of the required amount of washing it is possible to focus on the amount of paint that was once applied.

Of considerable importance is the air temperature, since at its high rates the process of evaporation of the cleaning agent is faster, so it may not be able to completely dissolve the paint, and it will also be necessary to recycle the metal.

How to remove?

Before treating a metal surface with a solvent remover, you must first clean the dirt and dust from the metal thoroughly, and then proceed with the application of the wash.

The washing composition is kept on the surface for approximately 20-30 minutes; the exact time is indicated on the product packaging.. In order to increase the evaporation time, the applied composition is covered with a dense polyethylene film.

When the paint has softened well, shrivels and begins to peel off itself, you can begin take it off with a spatula or wire brush. Remove dissolved paint is easy. After the paint is completely removed from the metal, it is necessary to clean the surface from the remnants of the wash. The package also indicates the means that are intended for this purpose.

If after the first application of paint remover failed to completely clean the surface, you need to repeat this procedure the required number of times.

If necessary, wash the powder paint from the aluminum surface should take into account the fact that for aluminum compounds are selected without alkali, which can destroy it.

Considering that solvents are chemical and toxic substances, it is necessary to take care of safe work with these materials in advance - it is recommended to use protective clothing, goggles and respirators.

Do not allow flushing substances on the skin or mucous membranes. If, nevertheless, it was not possible to prevent it, then the affected area should be washed with plenty of water.

After using the wash, it is advisable to thoroughly ventilate the room..

Based on customer feedback, it can be concluded that removing paint from metal is an uncomplicated and quick process that anyone can handle on their own. There should be no difficulty in cleaning the surfaces, provided that the cleaning agent is correctly selected depending on the type of the old coating, and all the points in the instructions attached to the packaging are observed.

The following video presents the test of washers for the rapid removal of old paint from metal.