Rubber paint: characteristics and scope

Rubber paint is a relatively new type of paint and varnish products on the building materials market. Such material has already gained popularity due to its excellent technical characteristics and wide scope of application. The paint-and-lacquer product is suitable for internal and external work, and is also easy to apply on most types of materials.

What it is?

Rubber paint is a type of paint and varnish products, which is made on the basis of acrylic and water. The product does not contain solvents, which indicates the safety of the paint and its environmental friendliness. You can carry out finishing work in an unventilated area, as the paintwork does not smell.Rubber paint got its name due to the elastic film, which is formed after drying and visually looks soft.

Typically, the composition of such a material includes the following components:

- water, which most often makes up five percent of the total volume; This component is used as a solvent;

- acrylic latex is necessary to obtain a durable and elastic coating;

- organic solvent coalescent plays the role of a temporary plasticizer and promotes film formation;

- antifreeze makes the coating resistant to low temperatures;

- antiseptic substances provide long-term preservation of the material, as well as prevent fungal formations;

- special additives that affect the properties and application of paintwork.

This material must be stored at a temperature not below zero degrees.. Short-term exposure to low temperatures (not lower than minus twenty degrees) during material transportation is considered acceptable. In the case of freezing of the coloring mixture, it must be held in a heated room at a temperature of 25 degrees Celsius for 24 hours.More detailed storage guidelines can be found in the instructions for the material.

Special features

Like all paints and varnishes, rubber paint has its advantages and disadvantages. Due to its complex composition, rubber paint has many unique properties. We highlight the main advantages of this material:

- Good adhesion. This coating is easy to lay on most types of materials: wood, drywall, metal, cellular concrete, brick, and many others. It is worth noting that even galvanized steel sheets can be coated with rubber paint when other paints and varnishes are drained from such a material.

- The operating temperature range of such a coating is from -50 to +60 degrees Celsius.

- Resistance to precipitation.

- Good vapor permeability. Such quality is necessary for processing wooden products.

- Short drying time. Within a couple of hours at a temperature not lower than 20 degrees even the thickest layer of paint and varnish coating will dry.

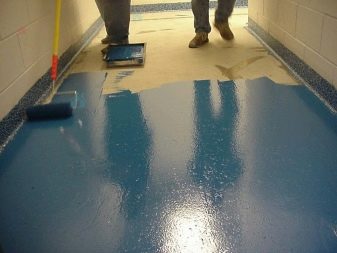

- After the paint has dried, a non-slippery surface is formed, which allows the use of such material for the steps of the porch or floors.

- Ease of application.

- Long service life of the coating, which can reach ten years.

- Health safety. The composition of the paint product does not include harmful substances.

- High strength coating.

The elastic film, which is formed after the material dries, can stretch by 400 percent. Due to this property on the paintwork does not form cracks. In addition, this material is able to protect from cracks the surface itself, on which it was applied.

Rubber paint, applied in several layers, perfectly protects products from rust, microorganisms and moisture. In addition to the significant advantages of paintwork, this material has its drawbacks. Consider the main disadvantages:

- The paint can peel off the surface to be treated if it (the surface) has not been properly prepared.

- Despite resistance to abrasion, certain areas of paintwork can deteriorate over time. It is quite easy to eliminate such a defect: it is necessary to cover the area with peeling off with a new layer of paint.

- The paintwork is matte and has no gloss.

Kinds

Rubber paint from different manufacturers may vary in color, composition, purpose, as well as the form of release. The following types of coating can be distinguished by application:

- Compositions for wood processing. They must include substances that prevent rotting and the formation of fungus.

- For cars produced special wear-resistant spray paint.

- For interior work.

- Extremely resistant to adverse conditions of use of the mixture are produced for external repairs.

Spray paint for vehicles can be applied to the old layer of paint. Previously you just need to carefully prepare the surface, cleaning and degreasing it. The elastic film protects the car from scratches and other defects that may form from tree branches, small stones or precipitation. As a result of external factors, the rubberized coating can be damaged, but a new layer of paint can easily be applied to the damaged area.

Liquid rubber can cover not only the outer part of the car.This aerosol is also used to paint the rims and some of the elements inside the cabin. It is easy to replace the paint: the old coating is quite simply removed, leaving no stains on the surface.

When carrying out exterior repair work, the paintwork is used for finishing residential and industrial premises, and also as a coating for some structures. The main areas of application of this material outdoors:

- sports facilities;

- facades of buildings;

- for roofing roof;

- garden paths;

- as a waterproofing coating on the surfaces of artificial ponds and pools;

- Walling;

- when carrying out road works for drawing a marking on asphalt.

Material

Rubber paintwork material can handle a variety of surfaces, both inside and outside the room. Suitable materials for this:

- plastic;

- all types of cellular concrete;

- asbestos cement sheets;

- asphalt;

- DVP, DSP, DSP, MDF;

- metal;

- wood;

- galvanized sheets;

- paving slabs.

Paint on a rubber basis on metal perfectly protects a surface from corrosion.However, it is worth remembering that it is impossible to apply such a paint and varnish product over rust.

Rusty surface must first be carefully cleaned. Mix for metal surfaces can be applied to some parts of cars. For these purposes, manufacturers produce a separate type of coloring coating.

Rubber paint reliably protects wood structures from the effects of moisture and precipitation. This coating is perfect for finishing wooden objects, which are located on the street.

Volume

The rubber paint produced is different in volume, which depends on the packaging. This coating is released in the following packaging:

- in cans;

- in a bucket;

- in the bank.

The volume of paint in cylinders most often makes 325, 390 or 450 ml. Mixtures in banks are available in volumes of 1, 3, 5 or 6 kilograms. In the bucket, the mass of the solution can be 12, 14 or 40 kilograms.

Colors

In addition to white and black paint, modern manufacturers produce material of many bright colors. The number of colors in the rubber paint line depends on the manufacturer and mainly ranges from 5 to 17 shades. Some manufacturers can make the desired tone to order or produce colors for white mixtures.

For painting cars produced blends with unusual color effects.You can purchase both matte and glossy finish. There are mixtures with a metallic effect and a luminous effect with the addition of crumbs.

Which is better to choose?

Rubber paint must be selected depending on the application and the material of the surface on which it will be applied. There are compounds with the addition of certain components that improve the technical characteristics of the paintwork material. When choosing a coating, you should pay attention to the following factors:

- assignment of work to be carried out (internal or external);

- the composition of the paint product;

- surface material;

- coating color;

- product manufacturer;

- the purpose of the room in which the repairs will be carried out.

Due to its excellent moisture resistance, rubber paintwork material can be used for exterior decoration, as well as in rooms with a high level of humidity (for example, for a bathroom).

For finishing wet rooms and wooden surfaces, you should choose the mixture, which include antiseptic components, which will prevent the formation of fungus.In the bathroom, you can paint the walls and ceiling instead of laying on the surface of the tile. In addition, the coating can be applied directly to the tile.

For painting the roof is better to choose a mixture with a high content of antifreeze. Rubber paints with a high latex content should be applied to the concrete surface. For the treatment of car parts produced a special spray paint in cans.

Tips and tricks

So that the rubber paint does not peel off after application, the surface of any material must be well prepared before painting. On the basis of it is desirable to clean the old finish, as well as remove dust, dirt, rust, mold and other types of pollution.

In addition, many materials need to degrease the surface. If the paint is applied to a surface with a porous structure, the structure must be pretreated with a primer. Concrete surfaces must be primed.

For a metal roof, before painting it is necessary to carry out a series of procedures for thorough cleaning of rust and degreasing the surface.The tree must be sanded and treated with an antiseptic before repair work.

Apply the paint product on a cleaned and degreased base should be in two or three thin layers. Before applying a new layer, it is desirable that the previous layer is completely dry.

Repair work should be carried out at a temperature not lower than 5 degrees Celsius. The humidity of the air should not exceed 80 percent. It is also not recommended to carry out finishing work in conditions of direct sunlight on the treated surface.. When painting products, the paint must be periodically mixed to a uniform consistency.

It is possible to apply mix on various designs and surfaces by means of a paint brush or the roller. Some manufacturers produce material in aerosol cans, which in certain cases makes the application process even easier.

Upon completion of the paint work do not forget about the care of the coating. You can use the following recommendations:

- Check the surface for defects. When peeling paint or deterioration of the coating on the problem area it is necessary to apply a new layer of paint material.

- Cleaning of the coating can be carried out only after the paint dries well and settles on the surface. It is recommended to wait a week after applying the paint material.

- Do not use aggressive detergents and solvents for cleaning. You can clean the surface with soapy water.

Manufacturers and reviews

Before you opt for one or another liquid rubber, you should familiarize yourself with popular manufacturers and reviews of their products. This approach will allow you to choose the best option paintwork material, suitable for price and quality.

Russian company Rubber paint manufactures products for tuning cars. The main direction in the production of this company is the manufacture of rubber paints for vehicles. Liquid rubber Rubber Paint is low cost and good quality. All products of this company have the appropriate quality certificates.

According to the staff of many service stations, liquid rubber for Rubber Paint cars is one of the best in the Russian market. The positive properties of the product include:

- ease of application;

- good quality at a low price;

- wide range of shades;

- soft-touch coating resembling soft rubber;

- does not form smudges on the surface;

- ease of dismantling;

- resistance to temperature extremes.

But for this product there is still a small amount of negative reviews. Buyers note the following disadvantages of coverage:

- unpleasant smell;

- stains remain after washing the surface at a car wash;

- high sensitivity to pollution;

- poor resistance to even minor mechanical stress.

Firm "SPE Rogneda" is a major Russian manufacturer of building materials. The company has a research base and a high-tech industrial complex. For the manufacture of materials used imported high quality components. Production technology is regularly upgraded.

SPE Rogneda "produces rubber paint" Dali " for finishing exterior walls, plinths and roofs. Paintwork is not only decorative, but also protective. This product can also be used to paint surfaces in rooms with a high level of humidity.

This material mainly has positive customer feedback. There are the following benefits of coverage:

- UV resistance;

- does not fade and does not deteriorate under the influence of direct sunlight;

- resistance to temperature range from -40 to +40 degrees.

The disadvantages of this material include a small number of colors in which paint is produced. This problem can be solved by adding a color scheme.

The company "Prom S" is engaged in the production of paints and building materials. Paints of this company differ in fire resistance. Each product has a corresponding certificate of quality.

Rubber paint company "Prom C" is produced under the brand name "Promkolor". This coating is ideal for almost any material, as well as for exterior repairs. Liquid rubber "Promkolor" has high quality and good technical characteristics. Customers note the following benefits of this product:

- keeps well on the surface;

- creates a beautiful coating;

- no odor;

- ease of application;

- frost-resistant;

- dries quickly.

In addition to the positive characteristics, some buyers have identified the negative qualities of the material. The disadvantages of paint "Promkolor" include:

- burnout under direct sunlight;

- exfoliates in some areas;

- liquid consistency.

In the modern paint and varnish market, liquid rubber of the following manufacturers is also popular: Tikkurila, Jassar, Optimist, Profilux, Super Decor. Buyers note the good quality of the products of these manufacturers, an acceptable cost and compliance with the declared characteristics.

On how to remove the rubber paint from the car, see the following video.