Features and scope of use of powder paint

Progress does not stand still, and each industry gradually gets its development. The sphere of construction and repair always keeps up with the times, and therefore is constantly supplemented with new technologies and products. Powder paint is a new kind of similar materials, which has found its place in a number of similar and is actively used for painting various products and surfaces.

Special features

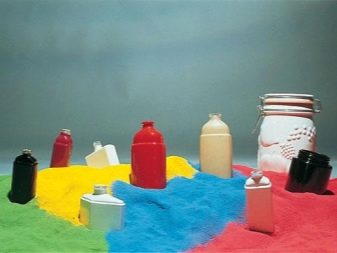

Powder paint was invented a long time ago, but right now it has become the most popular. Its peculiarity is that it is produced in the form of a powder and remains in this state even when applied to the surface. Such characteristics allow it to obtain a number of advantages related to the environmental friendliness of the product. Unlike ordinary paint, there are no organic solvents, so it is completely safe for humans.

The process of applying such material is carried out at the expense of special equipment, which allows you to work economically, without wasting more than necessary and not polluting the environment with elements that do not fall on the painted surface.

If we consider the composition of the paint, then it can be allocated only two components, particulate matter and air. A distinctive feature of this powder is its insolubility in water, the absence of odor and a certain color. By adding certain impurities, you can get the desired shade.

Considering the composition in more detail, you can find in it a hardener, a film-forming resin, a filler, a pigment and a target additive. The advantages of such paint are indisputable, and most importantly, when working with it there is no need to use a solvent, because the structure does not change its properties under any circumstances. The technical characteristics of this material allow it to be used to paint a wide variety of surfaces, among which are:

- metal surfaces;

- household appliances (microwaves, refrigerators and not only);

- sports equipment, equipment for athletes;

- furniture;

- lighting;

- glass and ceramic products;

- elements of machines.

Surfaces that are to be painted using powder paint can be very diverse. This type of painting acquires particular importance in the case of painting pipes inside, which are under high pressure. This material withstands high temperatures, so not every type of paint can be used for interior decoration.

Such an abundance of options for materials that can be painted with powder paint provides great opportunities. The properties possessed by the new coating make it possible not to be afraid for people's health, because the harm that some components of ordinary paintwork materials possess is completely absent in this composition.

Types and application

Unlike conventional paints, powder paints have a completely different principle of surface painting. Having electrical insulating properties, its particles are charged from the electric field, which differs from the surface that will be painted.Thus, falling on it, these tiny grains of sand just stick to the surface. At one time, it is not possible to paint the surface well, because this procedure is repeated twice. As soon as the surface was covered with a layer of paint, it is imperative that high temperatures be applied to bake it.

Depending on the surface on which it is necessary to apply the paint, whether it is outside or inside and some other properties allow classify this material into two main groups:

- Thermoplastic;

- Thermoreactive.

If we talk about the first option, it is often used for painting metal and chrome products. After the paint has been applied to the surface, a special protective film is formed due to the heating of the material, and then its cooling. It is heat-resistant, if the mode of operation with it is observed correctly, otherwise it will quickly dissolve the film.

Knowing the conditions in which the painted surface will be used, we can distinguish the following types of paint:

- Vinyl It is a base, but can be mixed with other additives and used for decorative purposes.The main element of the coloring matter is suitable for use only in the interior. The thickness of the layer is small, but even so, the level of protection is very serious.

- Polyvinyl chloride finds its application in the work on the external and internal surfaces of objects. It is applied both outdoors and inside it. Paints made on the basis of PVC have a composition that is resistant to chemicals and atmospheric phenomena.

- Polyethylene composition It has high rates of both physical and mechanical properties, which is why they are used to paint the pipeline.

- Paint with polyamide They are distinguished by good external indicators and are used to decorate the room outside and to perform all interior work.

If we talk about the second version of paints, they form a film after drying. The composition of such a coating does not experience any changes in the type of dissolution or melting, which means that the finished product will have resistant characteristics to various kinds of defects. Polyester and epoxy resins, polyurethane elements and acrylates are the basis of the composition.

Polymeric-epoxy structure allows you to successfully use this type of paint in engineering. The antistatic function is characteristic of polymeric powder paints. In order to give the car an interesting look, you can add a fluorescent pigment, so get a fluorescent paint for cars.

Epoxy substances in the composition allow to achieve high mechanical strength of the painted surface. The only factor that can contribute to the appearance of defects is ultraviolet radiation. Only mirror chrome can resist from similar factors. Polyester paint is just aimed at solving the problems of exposure to the sun, it does not respond to its radiation. This coating can be used to decorate any external surfaces that will retain their color for a long time.

Epoxy polyester paint contains polyester and epoxy frother in its composition, which start to react to each other in the process of hardening. These paints almost do not turn yellow and can withstand high temperatures.

Acrylate base resists when exposed to alkali.Pigment, which is responsible for color, can retain its properties for a long time. Dyes that are added to the powder paint, you can take a variety of, what is their uniqueness.

Of the difficulties can be noted only work with substances that are in different cartridges, you can not mix them together. The low-temperature environment is unacceptable for work with metal objects when they are painted.

Colors and textures

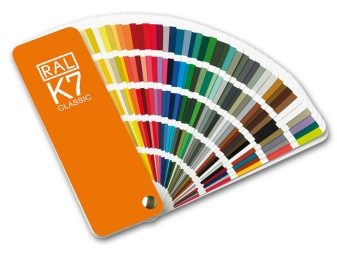

The color variety of powder paints is huge. When using additional dye can be given to the surface of the most diverse shade. In some cases, you can use several colors at once. There is no particular catalog in this case, each manufacturer creates their own colors.

It is customary to subdivide colors according to the RAL scale, which is considered to be the standard in paintwork. There are two types of colors:

- classic;

- designer

In the classic version, seven primary colors are distinguished, from which a huge number of shades originate. Each of them is produced in two versions:

- matte;

- glossy.

In order to make it easier to choose the desired color or shade, a special four-digit number for each color was developed, for example:

- For the yellow series it is 1000, 1005 and ends with 1034;

- For the purple series - 4001, 4005 and up to 4010.

As for the designer scale, there are much more colors here, namely 1688. It has a classic basis, but there is a separation in saturation and brightness of shades. In addition, the latest fashion trends generate peculiar color solutions. Popular is the color of antique, which gives an antique look to metal products. Painted surfaces can have a certain variety of shades, including bronze, copper and silver. Glossy surface is obtained under the influence of metallic effect.

You can paint the product under shagreen Its distinctive feature is the enlargement of the texture - it resembles an orange peel. With this option you can hide small surface irregularities. Paint helps to increase the durability of the material on which it is applied.

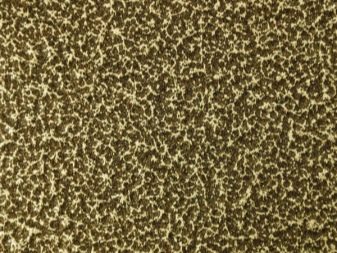

Another painting option is moire, which is characterized by the presence of fine-grained pattern.Externally, the surface resembles sandpaper, pleasant to the touch. The durability of the surface is enhanced, as is the scratch resistance. Painting under the crocodile skin helps to give the surface volume. You can use it indoors and outdoors, it is resistant to ultraviolet rays.

Another original option is painting with a hammer effect for those surfaces from which they want to get the look of old iron. The finished product has the form of a chased surface, on which they worked with a hammer. This paint is resistant to precipitation, temperature changes, vibrations, corrosion.

Metal parts can be applied chrome paint, which looks particularly impressive on cars. Powder paint for gold will be able to make any surface unique and give it an expensive look. The color palette of such paints has many options, but Black and white are still trendy and do not go out of fashion.

Manufacturers

If it is necessary to obtain the desired effect from the use of powder paint, it is important not only to comply with the application technology, but also to acquire good and high-quality products.One of the market leaders is the company. Pulver - The manufacturer of powder paint from Turkey, which exports products worldwide. All products have certificates and high quality indicators. The same good reviews can be heard about the company's products. Savipol, which also pays special attention to the quality of its goods.

Of the German manufacturers, the company Pulverit stands out, which produces quality products. Having on hand powder paint, you can safely paint aluminum and chrome parts, for which silver was previously used.

Every serious company that distributes its products around the world carries out serious tests of paints before putting them on stream and distributing them in different cities and countries. That is why, reading reviews about any global brand, one can see mostly positive reviews, and any problems that arise during the painting process are more often associated with the incompetence of those who perform the work.

Despite the abundance of foreign brands, you can always find good offers from domestic manufacturers.In this case, it is important to take a closer look at the choice, read the basic characteristics of the paint from the approved brands and compare them with ours.

The difference in the composition is minimal, or even none at all, and the price of Russian products is often an order of magnitude lower, which makes such a purchase more desirable.

Tips for choosing

In order to make the right choice of powder paint for a metal surface, need to focus on indicators such as:

- Manufacturer. It is best to choose well-known brands that have proven themselves in the market. Often they have in the assortment both expensive and more affordable paints, so people of different social strata can afford them.

- Selection of colors. Having a clear idea of how the finished coating should look like, you can accurately match the color and shade by selecting it from the catalog, which contains a huge number of options.

- The choice of texture for exterior painting. It is necessary to determine the type of surface - smooth or rough. By choosing the option with decorative irregularities, you can hide small surface defects, while maintaining all the properties of the material.

- Strength indicators and wear resistance depend on those additives that are in paints.

- Sustainability indicators to thermal and chemical effects. The surface coated with the polymerized layer is not subject to such effects, but at certain values it is possible to enhance the properties of the paint, making the necessary additives.

- Compliance with equipment. It is important that the paint matches the equipment with which it is applied.

- Storage. Choosing powder paint, it is important to pay attention to the shelf life and conditions.

- Packing Size. For each surface you need a certain amount of material, so in order not to buy too much, it is better to choose the appropriate packaging option.

Selection of powder can be done for non-metallic products, but it is important to know which one will be painted. For MDF it is one type, and for work on aluminum you will need another option.

It is possible to paint all surfaces only with the use of special equipment, which will make it possible to obtain a smooth surface with a uniformly applied layer of paint. It will protect the surface and will serve for a long time without loss of properties and color.

How to paint with powder paint in the next video.