Floor paint: assortment and features of choice

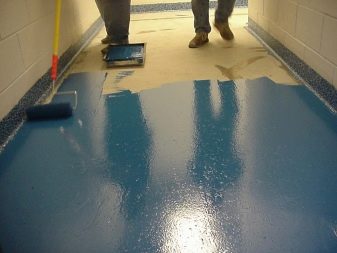

Often during the repair you have to face the need to paint the floor. Perhaps the old parquet flooring does not hold water anymore, sometimes there is a need to simply change the color solutions of the room.

Someone will need to paint the concrete, sheets of plywood or particleboard, forming the surface, but one way or another, it is paint that is basically the best finishing material for a floor covering.

Surface Features

There are a very large number of materials with which the floor is made or from which the floor is made, and each version has its own characteristics, advantages and disadvantages. For example, tile can be laid with a warm floor, and linoleum is cheaper than its counterparts.

Consider the most common types of surfaces:

- bulk floor;

- plywood;

- linoleum;

- cement;

- oriented strand board (OSB);

- wood chipboard (chipboard);

- fibreboard;

- tiled or ceramic tiles;

- corkwood.

Kinds and characteristics of paint

Paint can be:

- without smell;

- quick-drying (such dyes dry for less than half an hour);

- wear resistant;

- antistatic;

- natural (it is also called eco-paint);

- with filler;

- fireproof, providing fire safety.

Paint materials, based on the composition, are divided into several types:

- acrylic;

- alkyd;

- polyurethane;

- oil.

Acrylic

If we talk about dyes that have no odor, then the most common option would be acrylic water-based paint. She can paint any surface. As well as oil, acrylic is often used, if necessary, artistic painting.

Such paints and varnishes have a large number of advantages in comparison with analogues:

- The paint does not smell, therefore, the list of additives does not contain harmful toxins.

- The paint is safe for both builders and residents.

- Large fire resistance.

- Almost unlimited scope of application.

- These paints are very easy to cover any surface.

- High variety in the choice of colors.

- The coating is protected from cracking.

- Drying time, depending on the number of layers, may be less than half an hour.

- Such paints tolerate loads and resist abrasion.

- Ultraviolet radiation, high or dramatically changing temperature, a large percentage of moisture - with all this, such paint works fine.

As usual, it also does not do without minuses: such paints have a rather high price in comparison with others.

In addition, these dyes of the usual white color, therefore, in order to give the necessary shade, there is a need to purchase additional consumables - colorings. At this stage, however, this minus smoothly flows into a very significant plus: if you pick the right proportions, you can do it yourself, and using the services of specialists who are in many large hardware stores, you can achieve virtually any color.

In many acrylic paints in the production process, additives that are specialized in resistance to mold and fungus are sometimes mixed in, due to which the surface painted with such a composition will prevent their formation and spread.

This moment is relevant for kitchens, bathrooms, toilets and other rooms with high moisture content.

Alkyd

These materials are universal. They are used for work outdoors and indoors: such a wide range of paint applications has become possible due to their excellent performance characteristics. They perfectly prevent abrasion, retain their color gamut, brightness, saturation for a long time, these paints are not afraid of direct sunlight and detergents, mineral oils.

When applying several layers of this paint on a previously cleaned and primed surface, it will not change its performance even for several years. The film, created on the surface, resists temperatures from minus 50 to plus 60 degrees Celsius and does not lose outward beauty. Whereby, it is alkyd paint preferred for exterior decoration. They do an excellent job with tough external weathering.

Polyurethane

They are mixtures of different polymers. Such paints protect the surface well; their analogues do not possess these properties. Polyurethane paint is used both as a protective coating and as a layer of enamel.The material has an incredibly huge margin of safety.

The coloring composition is applied at temperatures from minus 10 to plus 30 degrees C. Such a parameter as the humidity of the air in this case is taken into account in the last turn: even at a rate of 90 percent or more, such paints can be applied to the surface.

At the beginning of painting it is necessary to prime the surface, otherwise the paint will fall badly, which will significantly reduce the service life of the coating and may lead to other problems.

The possibilities of exploitation of such compositions are completely amazing. They easily tolerate temperatures from minus 40 to plus 150 degrees Celsius. Thus, even boiling water spilled on the floor will not spoil it.

Polyurethane enamels can be divided using the following options: by the method of application and by the type of material that requires coating.

Application Method:

- spray can;

- tassel.

Materials may be:

- metal;

- wooden;

- stone.

It is often necessary to protect these types of surfaces from the environment.. When using polyurethane paint for metal products, it is very important to prime them.

Wooden surfaces require thorough drying.Due to the fact that the tree absorbs too much all the liquids that are applied to it, it requires the use of two or more layers of coating. Otherwise there is a chance to get a muddy color floor.

The more layers will be applied, the better the color will be revealed.

Oily

Created on an oil basis, their feature is the absence of sharp odors. This composition consists of drying oil and pigment impurities, where the drying oil performs the function of a diluent. Such paints are both color and colorless.

Used for painting metal or wood products, plaster and many other materials.. Along with this, oil paints are used when there is a need for decoration - for inscriptions, drawings, patterns and other small details. The disadvantage is that they are relatively long-lasting.

Floor paint varnish

Very often, professional builders and amateurs are engaged in repairing using lacquers without color, impregnation and protective glazes. The main features are that they combine visual appeal, excellent wear resistance, moisture protection, UV resistance and the prevention of natural aging.There are varnishes containing pigments, additionally emphasizing the natural structure of the tree.

Cons: transparent coating needs constant updating - at least once every two or three years. These include polyurethane varnishes, which provide tinted wood, preserve its original appearance, and emphasize the unique structure of the tree, instead of its coloring.

Manufacturers

We list the most famous manufacturers of paints and varnishes:

- Tikkurila - one of the leading companies for the production of paints and varnishes. Representative offices operate in Sweden, Finland and Russia. The company supplies materials to stores in any price segment: both economy and premium or medium solutions.

- Aquastrong - this company supplies the market with high-quality paintwork materials for painting concrete, cement and brick floors in exposed areas, including garages and warehouses. This coating is highly resistant to moisture and alkalis, as well as perfectly cope with oils, gasoline, saline solutions.

- Lacra - one of the largest manufacturers of paints and varnishes in Russia.The products of this company are manufactured in factories of Russia, Germany, Poland, Switzerland, Estonia, France and Canada. By production the most advanced technologies are applied. The company's products meet the highest international quality standards.

- "Prestige" - it is a paint and varnish holding, which has the most modern and innovative manufacturing enterprise. In the shops installed the latest equipment from world leaders. The first production line was launched in 2005, since then the company's products have repeatedly won various awards and certificates, and, most importantly, positive feedback from satisfied customers.

How to choose?

When choosing a suitable dye material consumption is considered to be a very important criterion. On average, as indicated by manufacturers, consumes 1 liter per 1 m².

Another important point is the interior design: in some cases it is better to use light paint, in others - dark.

Needles or hardwood always look great on the floor. But to preserve it, protect it from rotting, cracking and deformation, it is necessary to soak in antiseptic solutions and apply paintwork materials.

To select a floor or staircase, consider the following:

- Breed and texture of wood.

- Time and intensity of exploitation of the floor.

- The percentage of humidity, temperature and other conditions of the room.

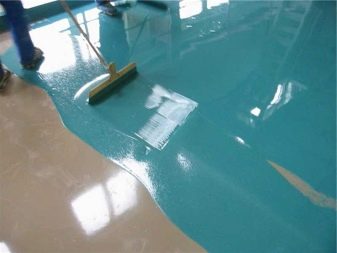

In the apartments, self-leveling floors are used very rarely, but this coating is suitable for various industrial, commercial or warehouse premises. Concrete is also used in a private house: in garages, basements, storage rooms, waiting rooms, as well as on balconies, open verandas, courtyards, terraces, etc. or toilet.

Concrete floors have high strength and durability, they have no seams, but such coatings, in the absence of proper maintenance, are too prone to dust accumulation on the surface and have a nondescript appearance. Therefore, the coloring of such a floor is a very important stage for increasing practicality and improving its aesthetic appearance.

In order not to be mistaken in the selection of coatings for concrete floors, the following factors are taken into account:

- Open or closed room.

- The temperature and humidity of the environment.

- The level of strength, anti-static, elasticity, chemical wear resistance.

- The required service life of the coating.

From the video below you will learn how to paint the floor in a wooden house.