How to apply concrete contact on the walls?

When repairing or building, you may have an urgent need to glue together two materials that can not dock. Until recently, such tasks set even experienced masters in a stupor. Now to solve this problem using concrete contact. It allows you to combine with each other absolutely any product.

Features and specifications

Before starting work, it is necessary to understand what concrete contact is, how to use it properly. Many people believe that concrete contact is a common primer or its substitute. This is wrong, although they are similar in function: concrete contact improves conditions for working with any surface.

Before the appearance of concrete contact on the building materials market, the process of plastering ceilings was difficult and time consuming. It took a lot of different materialshowever, this did not guarantee successful work.

When using concrete contact, the work time was reduced, the quality of plastering improved. This composition is used for interior work, facades. Without the use of such a solution, decorative plaster may peel off within a year, which is not included in the plans of most consumers. Concrete can be applied to any surface. In this case, it is possible not to remove old coatings: this solution will increase adhesion in any case. The structure includes:

- the basis of polymers;

- quartz or quartzite;

- cement;

- special supplements.

When using concrete contact, a rough layer is formed, to which any glue and material can be fixed. The main characteristics of the finished composition should include low consumption and good waterproofing. All components of the concrete contact are allowed to use it with dusty bases. Sand from quartz increases the adhesion (especially with wooden surfaces), creates a rough layer.

Many of the additives in the composition, prevent the formation of mold and fungus. When used correctly, the composition retains its properties for several decades.The parameters that may vary depending on the working conditions include the consumption of the composition and the time of drying. The average consumption ranges from 250 to 450 g per 1 square. m surface.

Drying time is completely dependent on the humidity in the room, an average of 150 minutes.

Kinds

There is a large selection of ready-made concrete-contact compositions. Due to carefully selected proportions, all components play a certain role. After purchase, you only need to mix the contents: the solution will be ready for application to the surface.

Some people believe that you can prepare this composition yourself. However, considering that it is very difficult to calculate the proportions yourself, the need to purchase various materials and the time to prepare a solution, it is worthwhile to think a few times whether such a procedure would be beneficial. The price of ready concrete contact is acceptable, it does not need to be adjusted before application.

Consumption

This indicator can vary from 100 to 500 g per 1 sq. Km. m surface. Less consumption is obtained when applying the solution on the tile or painted walls (up to 150 g per square meter). Greater consumption is observed when working with brick or concrete surfaces: it ranges from 350 to 500 g per 1 square meter. m. The remaining surfaces have average consumption.

Application details

Applying a concrete contact with your hands does not require special skills. Absolutely everyone will cope with this task. Before starting work, clean the surface. Although some manufacturers claim that the solution can be used even on dusty surfaces, it is clean surfaces that guarantee high adhesion between materials. You can ignore small cracks - the solution will flood them.

To increase adhesion, it is better to treat the surface with a conventional primer. This action will make the surface cleaner and strengthen the top layer.

After priming the consumption of concrete contact will be reduced. It is possible to work with this solution at a temperature of from +5 to + 30 degrees. Work in a room with a negative temperature will be difficult, the drying time will increase. When freezing all the properties of the solution deteriorate, the work becomes meaningless.

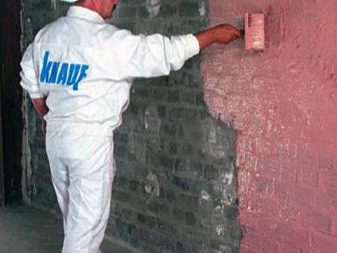

Apply concrete contact necessary foam roller or using a large brush. The thick composition is easily held on a roller or brush, it is distributed evenly and easily. Requires the same pressure on the tool.

It is better to continue finishing work immediately after the solution is completely dry, so that a layer of dust does not have time to appear on it.

Useful tips and tricks

In addition to the basic rules, there is a huge amount of advice from professionals working with concrete contact. Consider the basic recommendations.

- Do not use concrete contact on bitumen mastic. Increased adhesion will be minimal, the use of the solution in this situation is unjustified.

- In no case is unacceptable to dilute the composition with water or add any components by hand. It can only be diluted with water if the manufacturer has indicated this on the package, and in the dosage indicated on the package.

- It is better not to apply the composition to the entire surface at once, but only to the part on which you will quickly have time to carry out further finishing works.

- It is possible to use the solution for a long time only if you follow the rules of storage indicated on the package. If you notice that the composition has thickened or badly dries, it is better to buy a new package of concrete contact.

- It is possible to use this material when working with any surface: it is suitable for the floor, walls or ceiling.

- During the work with this solution it is not necessary to carry out additional processing of a surface.

- You can use concrete contact only after you have fully studied the instruction.

If you follow the simple rules, you can make repairs easier. In many cases, concrete contact is a necessity, it can be used as an alternative to the primer.

For information on how to apply concrete contact on the wall, see the following video.