Varieties of primers for the floor: how to choose?

Today in the shops of building and finishing materials you can find different types of primers, designed for different reasons. Recently, high-quality flooring compositions have become very popular, because with their help you can not only level the surface with waves and differences, but also provide it with enhanced waterproofing characteristics. Today we will talk about the existing varieties of floor primers.

Purpose

Primer is one of the most common and sought-after finishing materials. It is used for different purposes. Consider them in more detail.

- Using a quality primer, you can level the surface of the subfloor.Many finishing materials (for example, porcelain tile, laminate, parquet, tile or linoleum) must be laid on a prepared base. To achieve the desired effect, it is simply impossible to do without soil.

- The primer is often laid on a cement screed. Due to this tandem, cement foundations become more pliable in operation. Laying on them other coatings becomes much easier.

- Finishing flooring materials that have been laid on the foundation, covered with soil, have a longer service life. This effect is achieved by increasing the degree of adhesion of the coatings. Due to this feature, the finish is not subject to the formation of cracks, chips or delaminations.

- Concrete floor surface becomes more durable after priming. Therefore, many consumers rush to repair floor bases with high-quality primer during repairs. Without it, concrete over time can break down.

- The primer is designed to protect the base of the floor from aggressive chemicals. Few people know that dampness and substances dissolved in it are able to penetrate the putty for various reasons.Often this leads to chemical reactions that have a detrimental effect on the finishing materials. With the help of high-quality primer mixture such problems can be forgotten.

- The primer can significantly save on subsequent finishing materials, because it closes the pores in the base structure.

- It is necessary to preserve the natural moisture level at the base. A surface that has not been trimmed with a primer is, as a rule, overdried or too damp, and this has a very detrimental effect on the durability and strength of the floor base.

- Special primer compositions with a high degree of moisture resistance are often used if the floor heating system is present in the room. Such mixtures are often used before laying tiles in rooms with a high level of humidity (kitchen, bathroom, bathroom).

The primer is necessary for me to prevent dust from accumulating on the base finish. It is a very useful addition to the subfloor. Due to it, the base and decorative material will serve for a long time, without causing any trouble.

Types and properties

Currently, there are several varieties of primers. Each of them has its own characteristics and properties. Due to the choice provided, a suitable composition can be purchased for any conditions.

Alkyd

Such primer mixtures are found in stores quite often. They are purchased primarily for finishing the whimsical surfaces of wood before painting them. There are two subspecies of alkyd primers. The choice of the best option depends largely on what kind of paint you plan to transfer to the wooden floor. After complete application, such mixtures dry in about 10 hours.

Glyphthalic

These types of soil are quite popular. They are in demand, as they are ideal for finishing metal surfaces. However, it is possible to use glyptal solutions only in the conditions of enclosed spaces in which there are no drafts. Such primer formulations dry in a day (sometimes a little longer). Today, in stores you can find a good alternative to the glyphthalic primer - zinc-rich mixtures.

Epoxy

This two-component mixture is most often used to decorate concretegrounds. With it, the surface of the base can be made more durable, reliable and durable. In addition, after applying the epoxy composition the floor becomes more moisture resistant. Epoxy mixtures are often used as a separate layer. They have high adhesion. The composition of epoxy primer is not aromatic solvents, so when working with him you will not feel an unpleasant and sharp smell.

Perchlorvinyl

Such primers are used for brick and plastered surfaces. However, experts say that perchlorovinyl formulations should be used only in cases where the object being processed is located on the street. These types of soil are often applied to concrete street platforms or screeds. If you are going to purchase this primer mix under the screed, then it should be selected based on the material from which the base is made (and not the screed itself). Perchlorvinyl mixtures dry quickly enough. It takes about 1 hour.

Polyvinyl acetate

These types of primer can be used if you plan to paint the base with polyvinyl acetate paint.The type of material from which the floor is made does not matter. This type of mixture dries in record time: it takes only 15-20 minutes.

Polystyrene

These types of soil should be purchased for wooden floors and plaster substrates. In addition, polystyrene primer compositions are often used for the subsequent installation of self-leveling floor. It is worth noting that polystyrene compounds can not be called environmentally friendly and completely safe.

In their composition are aggressive and toxic compounds. For this reason, it is strongly not recommended to use such mixtures in closed spaces, otherwise you may be harmful to your health.

Acrylic

One of the most popular and sought-after varieties of primer is acrylic blends. Such products are distinguished by the fact that they are suitable for almost any outdoor base. In addition, they do not have an unpleasant and acrid smell, so working with them is quite easy. Many consumers choose acrylic blends for base treatment because they can be used to finish a concrete floor.

The solutions penetrate into its structure to ensure increased adhesion. Such properties are especially useful if you plan to lay laminate or linoleum on the floor. Also, acrylic compositions can be used when making floor screed.

It is not recommended to use acrylic compounds for the finishing of dark iron: they can cause corrosion on such bases.

If you do not want to spend extra money, you are confident in your abilities and knowledge, you can make a primer yourself. Today, there are many different recipes, adhering to which you can create a really high-quality and practical soil.

It is important to carry out the manufacturing technology as accurately as possible., in order to finally get the liquid the desired consistency and quality. Consider the features of the choice of purchased material.

How to choose?

As you can see, the range of primers is quite rich. Every consumer has the opportunity to choose for themselves the ideal option. Note the specific advice of experts in the field of construction and repair.

- The choice of the optimal composition, first of all, depends on the material from which the floor is made.For example, for finishing a concrete base, experts recommend buying acrylic or epoxy mixture.

- If you want to buy a primer for the floor consisting of wood (chipboard, MDF, OSB), you should look for a special option that has the ability to deep penetration. Alkyd, glyptal, polystyrene and acrylic solutions are suitable for this description.

- If you are going to ground the floor in a room that is characterized by a high level of humidity or does not have heating systems, it is better to give preference to the composition in which there are special water-repellent components.

- If you are going to primer the floor base under the varnish, you should choose a colorless transparent composition. With it, you can successfully emphasize the structure of the tree.

- If you want to achieve the effect under the paint, then you should get a color primer composition.

- When the subsequent laying of a tile is planned, it is worth using a primer which will provide the minimum absorbability of the basis. This is necessary so that the base does not take water from adhesives.

- For the floor under the fill is ideal polystyrene primer.However, when working with it, one should not forget about its toxic composition.

- Do not look for too cheap primer. Too low price may indicate poor quality of the composition. It is better to buy branded products of well-known and proven brands. Such mixtures will delight you with the durability of the floor covering and high quality.

Manufacturers

Today in the market of finishing materials there are many manufacturers that produce high-quality primer mixtures for floor finishing. From the long list should be highlighted the most popular brands. These include:

- Dulux;

- "Bolars";

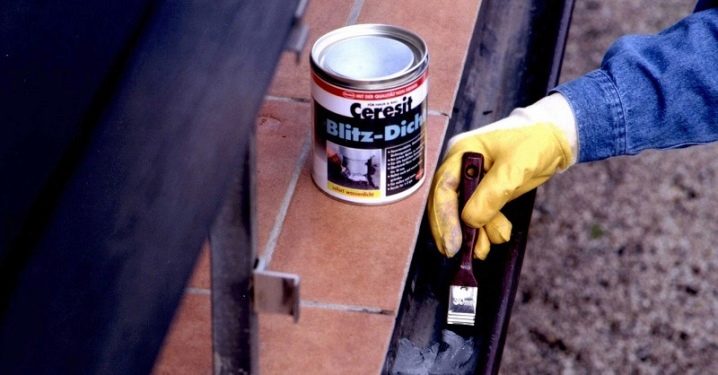

- Ceresit;

- "Expert";

- Clims;

- Uzin.

Products that produce these brands, is very popular among modern buyers, because of its high quality. The range of these companies is quite rich, so every consumer will be able to choose the optimal composition.

Application tips

Priming the floor is not the most difficult task. Even an inexperienced home master can easily cope with such work. Let's get acquainted with some simple tips of professionals who will help you to coat the floor base with a primer.

- Do not forget about the preparation of the foundation for the future application of soil. It needs to be dried if it is raw. In addition, from the floor you need to remove all debris, dirt and dust.

- Grind the substrate if necessary. After this cleaning should be repeated.

- It is necessary to prepare the mixture, based on the instructions that manufacturers indicate on the original packaging. If you do not want to mess with the dry composition, you should purchase a ready-made mixture that does not need to be prepared for finishing work.

- After that, you need to dip the roller in a container with a prepared primer. Apply the mixture on top of the cleaned base until dust has settled on it.

- First, the roller should be led parallel to one of the walls, and then perpendicularly (along the same wall). Such an application is considered the highest quality and most convenient.

- After that, you should properly grease all the corners in the room. You can use a brush. We should not forget about the joints, which are located between the floor and the ceiling.

- In no case do not miss any parts of the floor during the processing of the soil. Too much primer should not be applied too.

- Soil must cover the entire area of the rough floor base. After that he needs to be allowed to dry and then apply a repeated layer of the composition.

- If it is inconvenient for you to work with a roller, then you may well use a special brush with a long handle.

Security measures

Working with any primer mixture, we must not forget that it is a chemical product. Experts strongly recommend the use of thick gloves when working with such compounds. Try to avoid getting the solution on exposed skin. Sometimes the masters do not manage with ordinary gloves - they specifically acquire paint overalls. To some people, they seem uncomfortable, but in matters of security, this defect is not so important.

Do not forget that many types of primers are quite difficult to wash off from different surfaces. If you accidentally stain your hands with such compounds, they will remain dirty for several days. Polystyrene primers are rightfully recognized as the most toxic and hazardous to health. It is necessary to work with them especially carefully and prudently.In no case do not finish the floor with such a mixture in a fully enclosed room. Experts recommend that you always wear special masks and the highest possible gloves when working with polystyrene primers.

How to primer the floor, see the next video.