Enamel on metal: features of the choice and application

To paint any metal surface, you can use different compositions, which are represented by different price categories. The main thing is to choose the highest quality enamel for metal.

Special features

Enamel metal has a very important function: it protects any surface from corrosive action. It is used only for those metal objects that will regularly stay in the air or be in the water. At the same time, saturation should be emphasized, since paints for metal products give their appearance sophistication and beauty. But if you choose a bad product and do not comply with certain technologies, the coating will not look aesthetically pleasing.

When choosing enamel for metal, you need to look at its chemical composition, since it is not suitable for every surface.Coloring wood is much more difficult than applying paint to metal products. Many paints can not be used for galvanized objects, because they have very little adhesion.

Varieties and Characteristics

Enamels for metal are represented by such basic types as:

- oil;

- alkyd;

- acrylic.

Oily view paint is a budget and can be purchased at any building store. But there is a problem, because these enamels can hardly be called quick-drying. Because of the sun, they quickly lose their appearance and begin to fade. Such products are poorly protected from rust and leave much to be desired.

Oil enamels perform their function poorly at high temperatures. For example, for boilers or radiators their use is very dangerous, so it is better not to try.

According to anti-corrosion enterprise alkyd enamels are better. They have an increased stability to adverse weather conditions, so they are often used when performing outdoor work. Experts say that the best choice is the acrylic versions, since they are made on water.

The advantage of this enamel is that it does not cause any harm to a person, and also has no unpleasant smell. Using matt black anti-corrosion enamel, you can give the coating an attractive appearance.

According to the resistibility of the powerful heating and the adverse effects of the outer sphere, combinations based on acrylic are not worse than alkyd analogues. This allows you to increase the period during which metal objects retain their aesthetic appearance. Enamel dries quickly, and everyone likes it. Despite the advantages of powder painting metal is prohibited to be made at home.

Heat-resistant and fire-resistant enamels have nothing in common with each other. In the first case, the plane should remain unchanged with possible heating, and in the second, protect the base from the influence of fire. A two-component mixture includes epoxy, these are substances that destroy corrosion. A standard polyester coating often forms a glossy look on primed surfaces.

In addition to these types, there is also a dielectric, polymer, oil and petrol resistant, weather resistant, chemical resistant.

The consumption rate per 1 m² depends on the application conditions and the type of material that will be processed.

Colors

The color range of enamels for metal can be completely different (glossy, matte). Most people buy yellow or white paint. Yellow paint is used on any objects, it is easy to block rust. In the white color most often paint radiators and other parts that tend to heat up.

Scope of application

Before you start working, you should tune in to the artistic process, as well as prepare the surface. If you do not adhere to this point, then rust will soon appear. Coatings are different in properties and application. When choosing a paint should pay attention to the requirements for its use. For example, coatings that can be used when painting interior surfaces will not work for metal tiles.

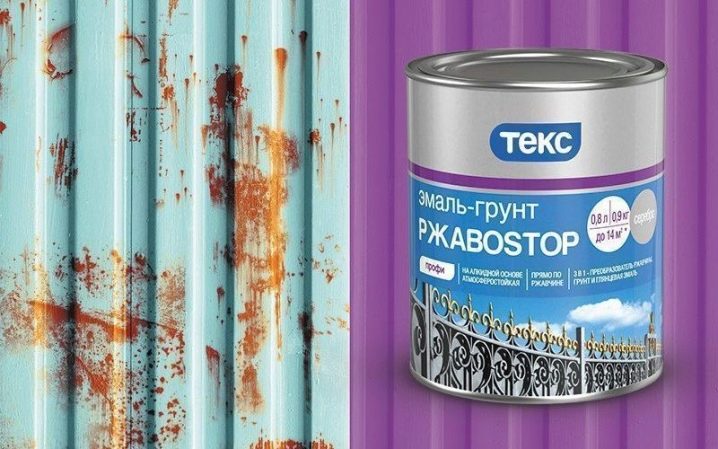

Manufacturers

Often people doubt which manufacturers are better. It is worth noting several companies whose products are very popular today. Company "Tex" produces high quality enamel for use on metal structures.

From among other manufacturers should pay attention to brands such as Tikkurila, Hammerite, "Commander".

Application Tips

Experts recommend to adhere to the following rules when working with metal enamel:

- First of all, you need to paint a small area, after it dries, you should look at it from the side. If you like everything, you can continue the workflow.

- It is necessary to process all corners with the help of special brushes. Rollers are used for the rest of the perimeter.

- A total of 2-3 layers are applied, but each of them requires application not earlier and no later than half an hour after the treatment of the previous layer has ended.

See the following video for a 3-in-1 Hammerlack düfa workshop on enamel metal 3-in-1.